A kind of nd-fe-b thin strip magnet and preparation method thereof

A nd-fe-b, thin strip technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of performance degradation, research inconvenience, and far difference in performance theoretical values, etc., to achieve good hard The effect of magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The first step, raw material preparation:

[0038] According to the content of each element after adding Alnico alloy to Nd-Fe-B alloy, calculate the atomic percentage content of each element in the alloy, use Nd 11.36 Fe 81.17 B 5.67 al 0.54 Ni 0.40 co 0.74 Cu 0.09 Ti 0.01 Si 0.01 Nb 0.01 Express, and then calculate Nd according to the atomic percentage 11.36 Fe 81.17 B 5.67 al 0.54 Ni 0.40 co 0.74 Cu 0.09 Ti 0.01 Si 0.01 Nb 0.01 The mass percentage of the constituent elements in the composition is taken by weighing the component raw materials pure Nd, pure Fe, pure Al, pure Ni, pure Co, pure Cu, pure Ti, pure Si, Fe-B alloy and Fe-Nb alloy by mass percentage. This completes the preparation of raw materials. In the raw materials of the above-mentioned composition, B uses Fe-B alloy as raw material, wherein the content of B is 18~21% (mass percentage), and Nb uses Fe-Nb alloy as raw material, wherein the content of Nb is 50~ 80% (mass percentage);

...

Embodiment 2

[0048] The first step, raw material preparation:

[0049] With embodiment 1;

[0050] The second step is to melt the raw materials to prepare master alloy ingots:

[0051] With embodiment 1;

[0052] The third step, the preparation of Nd-Fe-B thin strip magnet products:

[0053] The Nd obtained in the second step 11.36 Fe 81.17 B 5.67 al 0.54 Ni 0.40 co 0.74 Cu 0.09 Ti 0.01 Si 0.01 Nb 0.01 The master alloy ingot is loaded into the melt quenching furnace, and after remelting, the melt is quenched on the cooling molybdenum roller rotating at a peripheral speed of 5m / s, and the element composition is Nd 11.36 Fe 81.1.7 B 5.67 al 0.54 Ni 0.40 co 0.74 Cu 0.09 Ti 0.01 Si 0.01 Nb 0.01 Nd-Fe-B thin strip magnet products; the magnetic properties of the thin strip magnet products are: intrinsic coercivity: 52.1kA / m, remanence: 0.21T, magnetic energy product: 10.2kJ / m 3 , the thickness of the thin strip magnet product is 78 μm, and the average grain size of the main...

Embodiment 3

[0055] The first step, raw material preparation:

[0056] With embodiment 1;

[0057] The second step is to melt the raw materials to prepare master alloy ingots:

[0058] With embodiment 1;

[0059] The third step, preparation of Nd-Fe-B thin strip magnet:

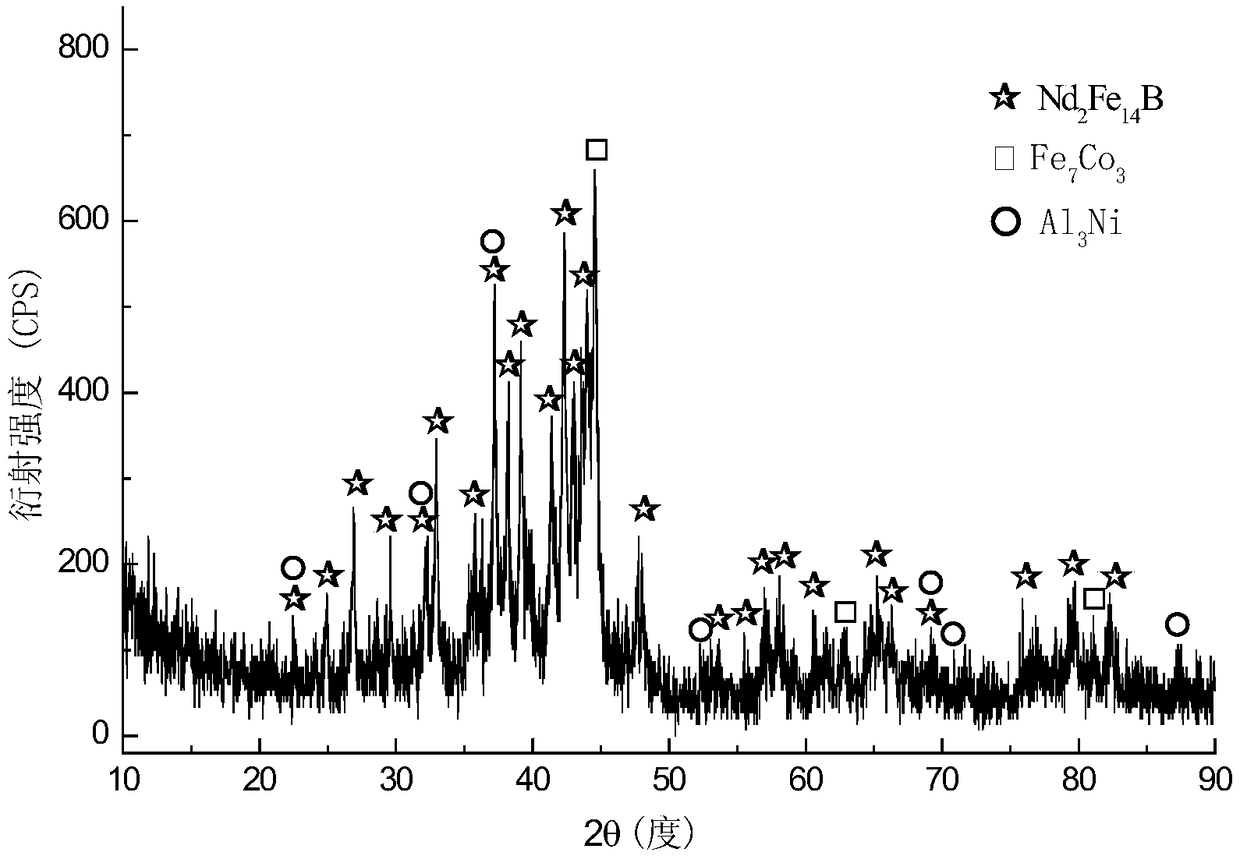

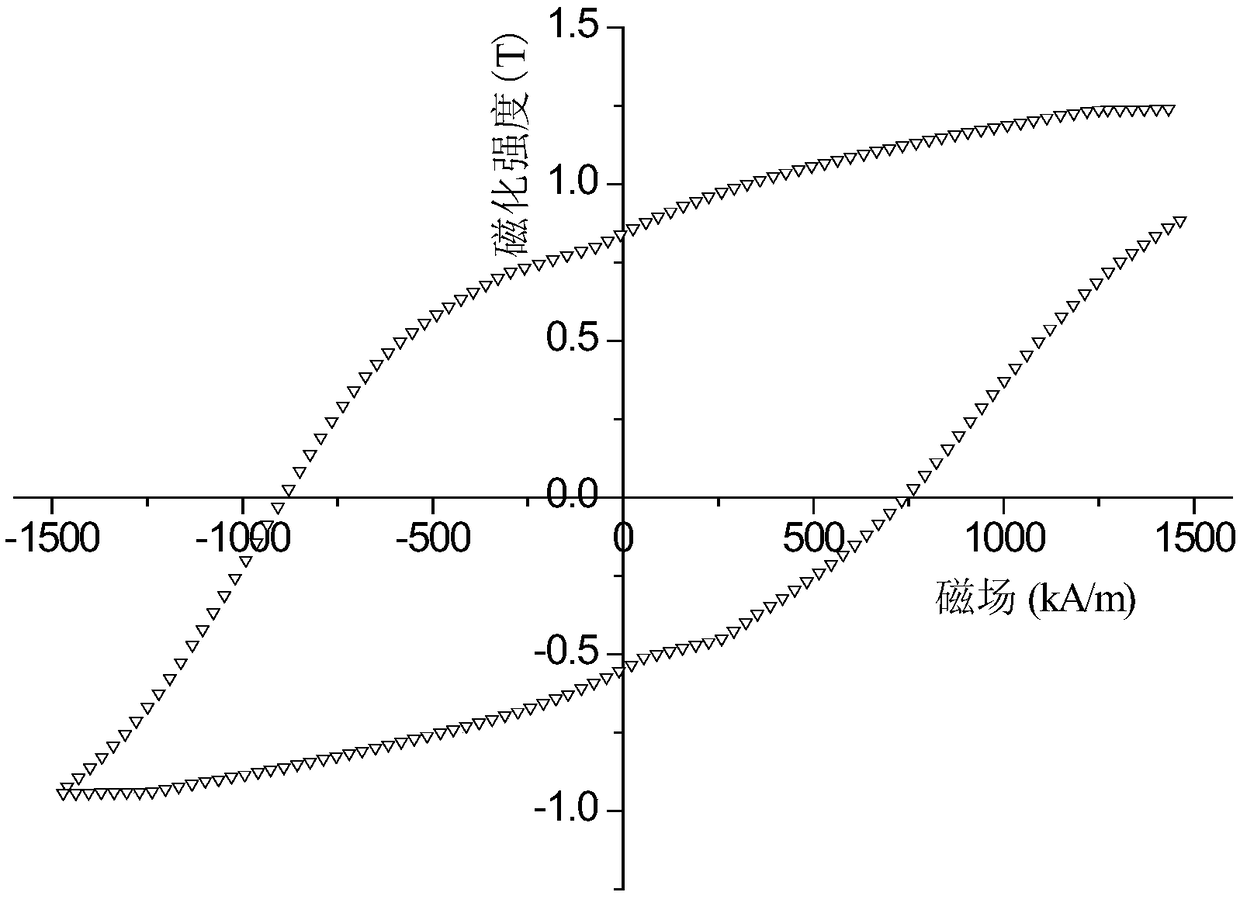

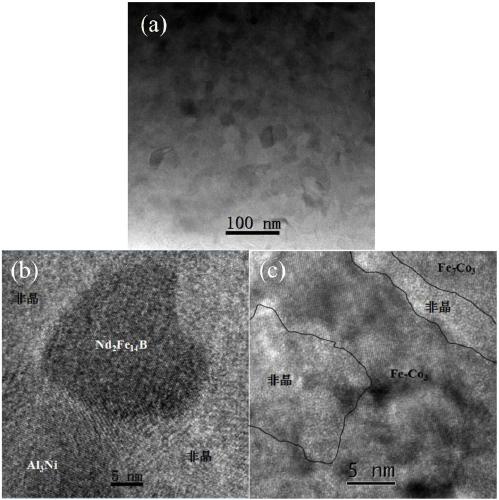

[0060] The Nd obtained in the second step 11.36 Fe 81.17 B 5.67 al 0.54 Ni 0.40 co 0.74 Cu 0.09 Ti 0.01 Si 0.01 Nb 0.01 The master alloy ingot is loaded into the melt quenching furnace, and after remelting, the melt is quenched on the cooling molybdenum roller rotating at a peripheral speed of 20m / s, and the element composition is Nd 11.36 Fe 81.17 B 5.67 al 0.54 Ni 0.40 co 0.74 Cu 0.09 Ti 0.01 Si 0.01 Nb 0.01 Nd-Fe-B thin strip magnet products; the magnetic properties of the thin strip magnet products are: intrinsic coercivity: 296.6kA / m, remanence: 0.42T, magnetic energy product: 26.0kJ / m 3 , the thickness of the thin strip magnet product is 52 μm, and the average grain size of the main crystal pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic energy product | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com