Automatic chestnut shelling machine

A sheller and automatic technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of low chestnut shelling efficiency and unsatisfactory shelling effect, and achieve the effect of high-efficiency shelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

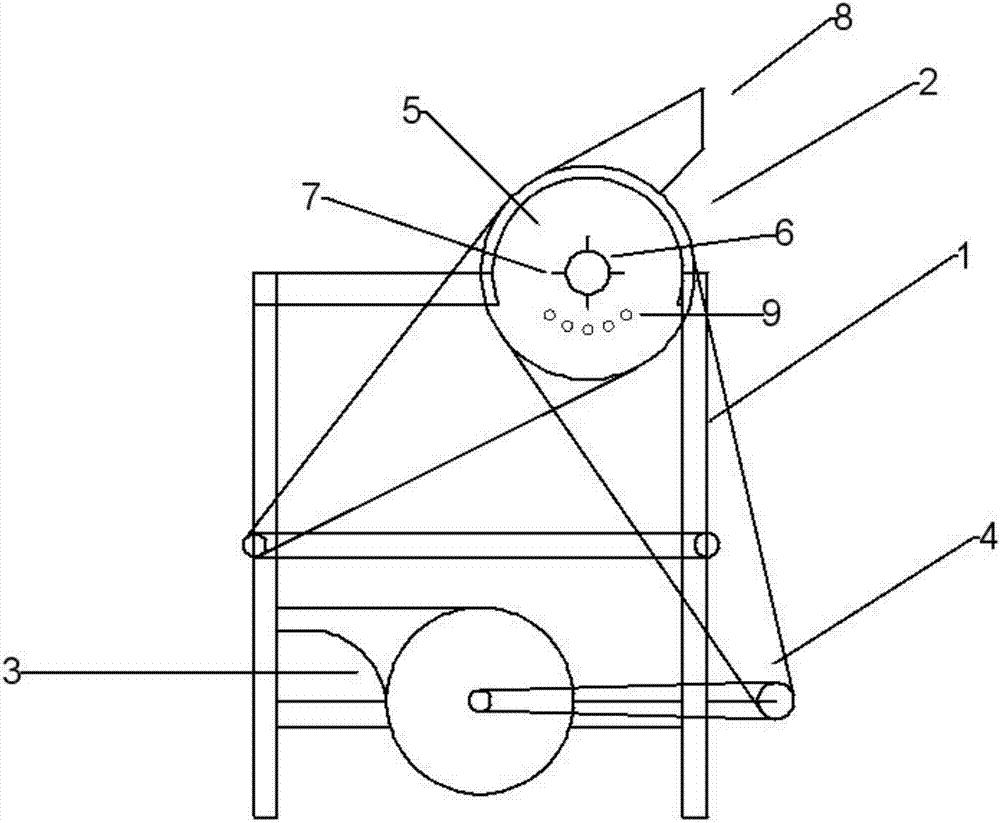

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] When in use, the chestnuts are put into the shelling device (2) through the feeding port (8), the shelling inner cylinder (6) is driven by the motor (4) to rotate, and the rotating shelling pieces (6) and the threaded steel grid (9) When the chestnut is squeezed, since the shelling sheet (6) is composed of iron sheet and rubber skin, the chestnut can be flexibly and evenly stressed without damaging the chestnut rice. Crushed chestnut burrs and chestnut rice fall to the conveyor belt. The conveyor belt is driven by the shelling outer cylinder (5) and the motor (4) through the belt. The quality of the chestnut burr and the chestnut rice is different and the force under the action of the wind is different, the wind generated by the blower (3) separates the falling chestnut burr from the chestnut rice, and the blower (3) is driven by the motor (1) to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com