Sanitary towel with three-dimensional leakproof enclosures and manufacturing method thereof

A production method and technology of hygienic products, applied in the fields of pull-up pants, hygienic pants, hygienic products manufacturing, sanitary napkins, and paper diapers, can solve problems such as short height, poor body feeling, and side leakage, so as to improve quality and comfort , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

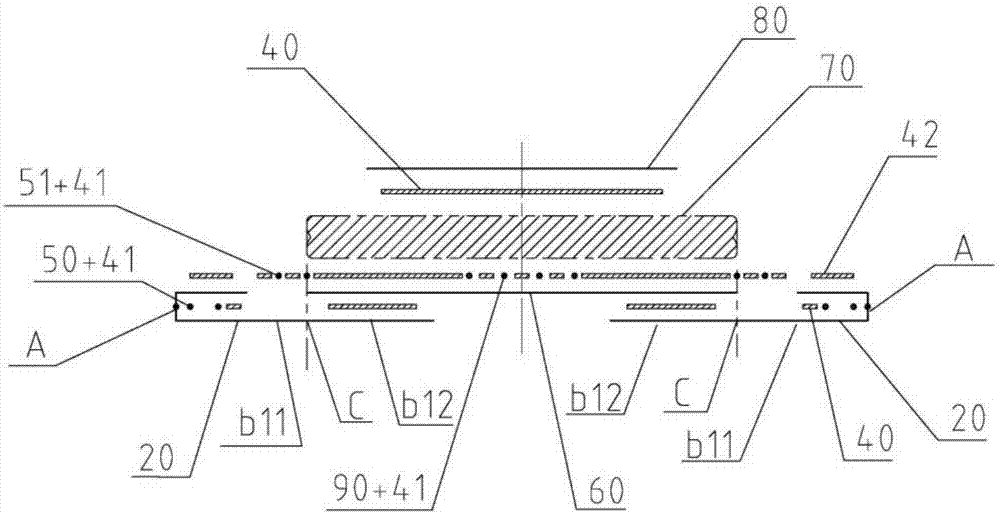

[0037] like Figure 1 to Figure 3 Shown, the preparation method of the sanitary article that the present invention has three-dimensional leak-proof enclosure, comprises the following steps:

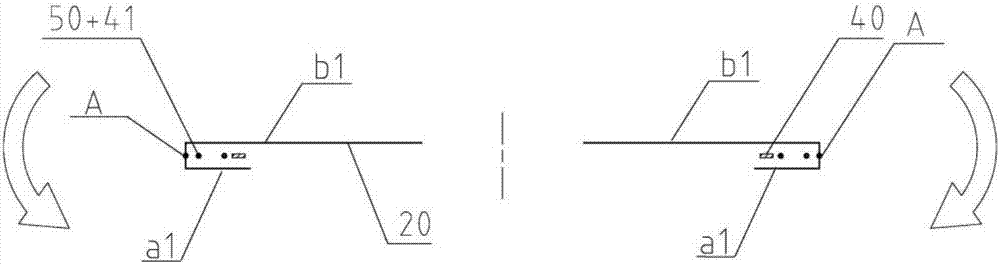

[0038] Step 1, the first cladding device 10 (see Figure 8 ) Bending down the two left and right guards 20 along the first covering position A to perform the first covering, so that the guards 20 are divided into the first covering section a1 and the first uncoating section a1 along the width direction. segment b1, and the width of the first covered segment a1 is smaller than the width of the first uncoated segment b1; the width of the first covered segment a1 can be properly adjusted according to the enclosure height of different products. The sum of the width of the first covered section a1 and the width of the first uncoated section b1 is the total width of the enclosure 20 .

[0039] Before the above-mentioned first coating device 10 performs the first coating, the first fixing glue...

Embodiment 2

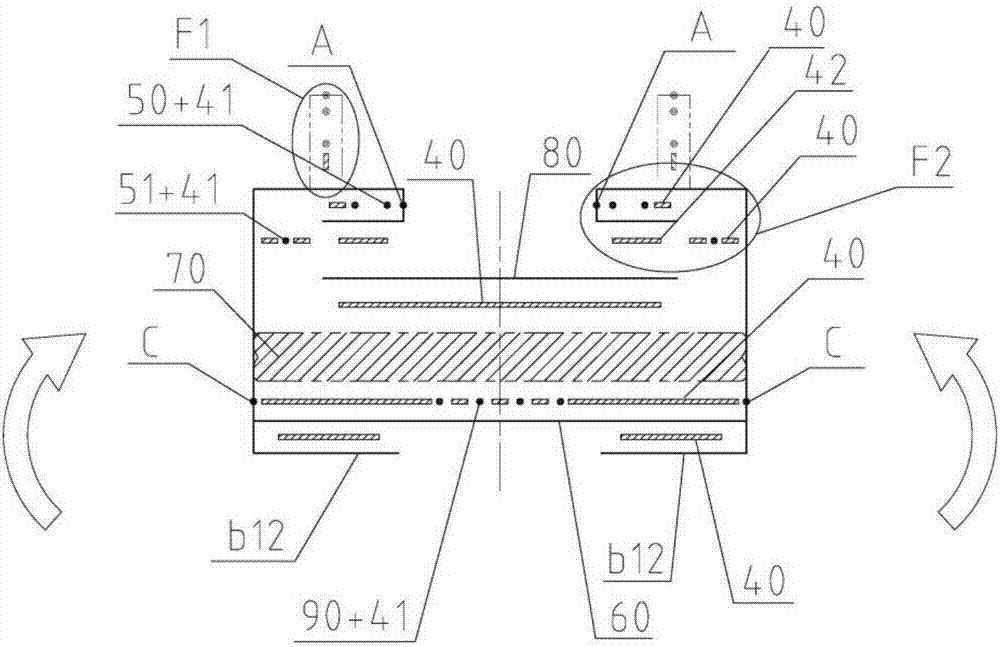

[0049] Such as Figure 4 to Figure 7 As shown, this embodiment is different from the above-mentioned embodiment 1. On the basis of the above-mentioned embodiment 1, a second coating process is added. The setting of the second coating process is to better form the inner double-layer edge protection twenty one. In this embodiment, the ends of the enclosure along the length direction are fixed to form two double-layer edge protections. In the middle section of the enclosure, due to the stretching effect of the inner enclosure elastic member 50, a ratio of implementation will be formed. In Example 1, the height is higher and the inner double-layer edge protection is better, so the three-dimensional leak-proof effect of Implementation 2 is obviously better than that of Example 1; and in Example 1, the end of the enclosure arranged along the length direction Only one double layer is formed (ie the inner double edge), but in the middle section of the enclosure, an inner double edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com