Single-column lifting machine

A lift and single-column technology, applied in the direction of lifting devices, etc., can solve the problems of high use cost, high cost, complicated control process, etc., and achieve the effects of wide application range, convenient adjustment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

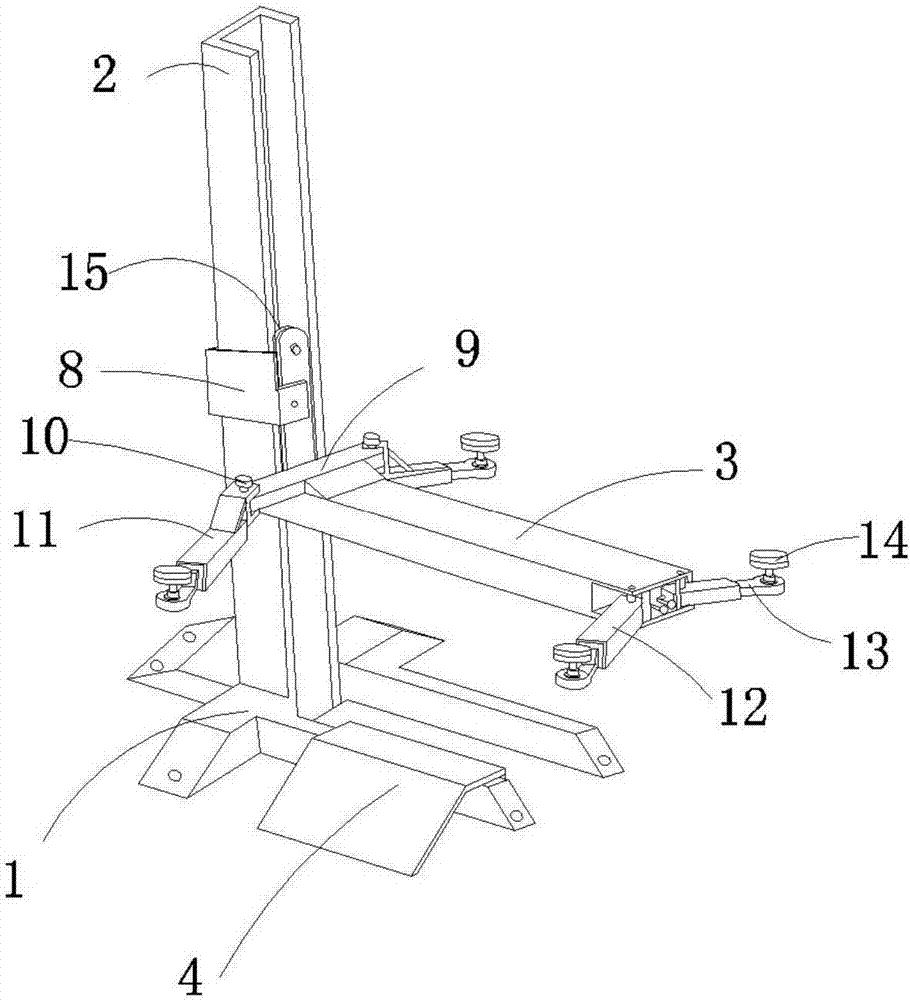

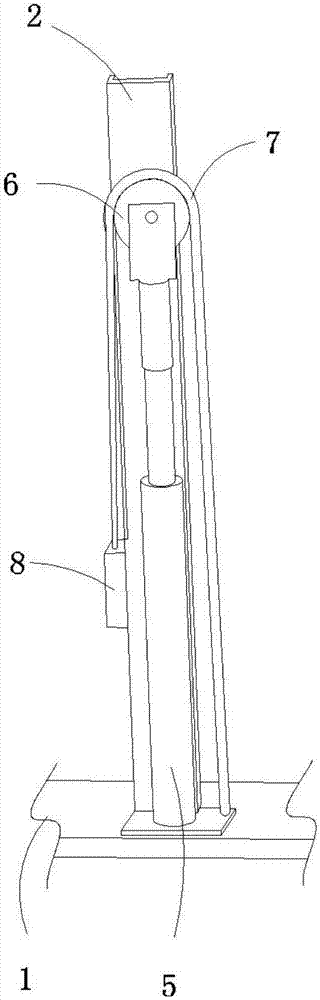

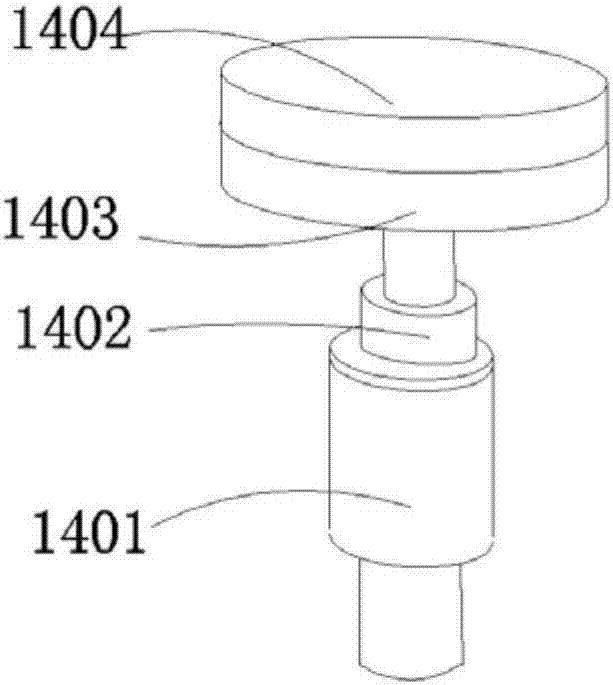

[0025] Examples, see attached Figure 1~3 , a single column lift, comprising a base 1 and a column 2 fixed on the base, a lifting arm 3 is slidably connected to the column, the column is an angle steel structure, and a slide rail is installed in the angle steel channel of the angle steel structure, and the slide A slide block 15 is installed on the rail, and the lifting arm is fixed on the slide block; a lifting assembly that drives the slide block to move along the slide rail is installed on the column.

[0026] The upper board 4 can be overlapped on the base, and the upper board does not need to be installed, as long as it is overlapped on the base, it can be collected immediately after use, and the operation is simple and convenient.

[0027] The base is provided with mounting holes capable of fixing the base on the floor of the workshop or the floor of the factory building, and the base can be fixed on the floor of the workshop or the floor of the factory building through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com