Anti-overflow method for cooking equipment

A cooking equipment and anti-spill technology, which is applied to beverage preparation devices, kitchen utensils, home utensils, etc., can solve the problems of heating power adjustment, abnormal performance, and inability to automatically judge, so as to avoid overflow and improve the effect of anti-spill performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

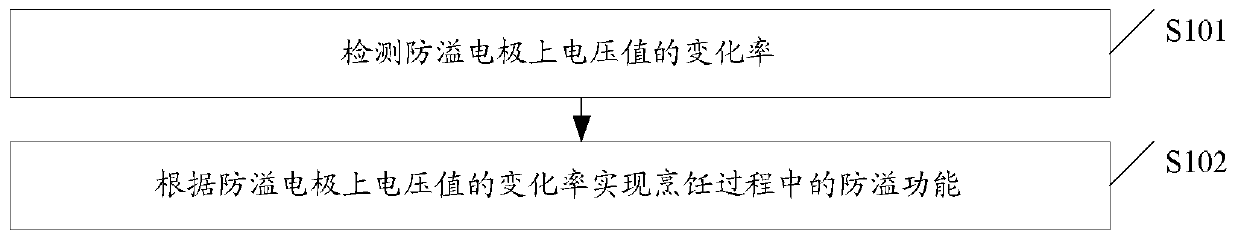

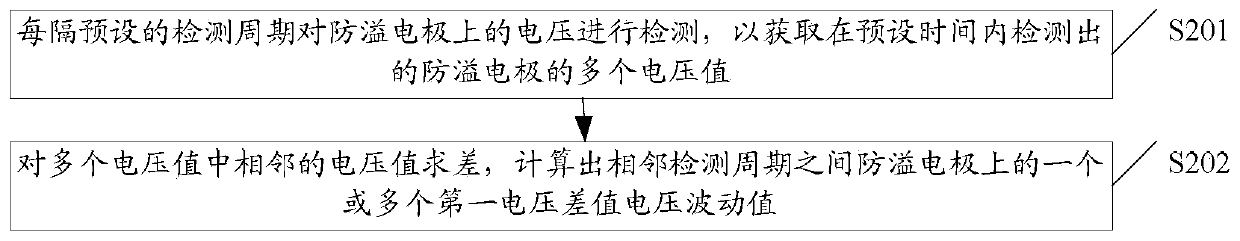

[0060] A method of preventing overflow of cooking equipment, such as figure 1 As shown, the method includes S101-S102:

[0061] S101: Detect the rate of change of the voltage value on the anti-overflow electrode; the rate of change of the voltage value refers to the range of change of the voltage value within a certain period of time.

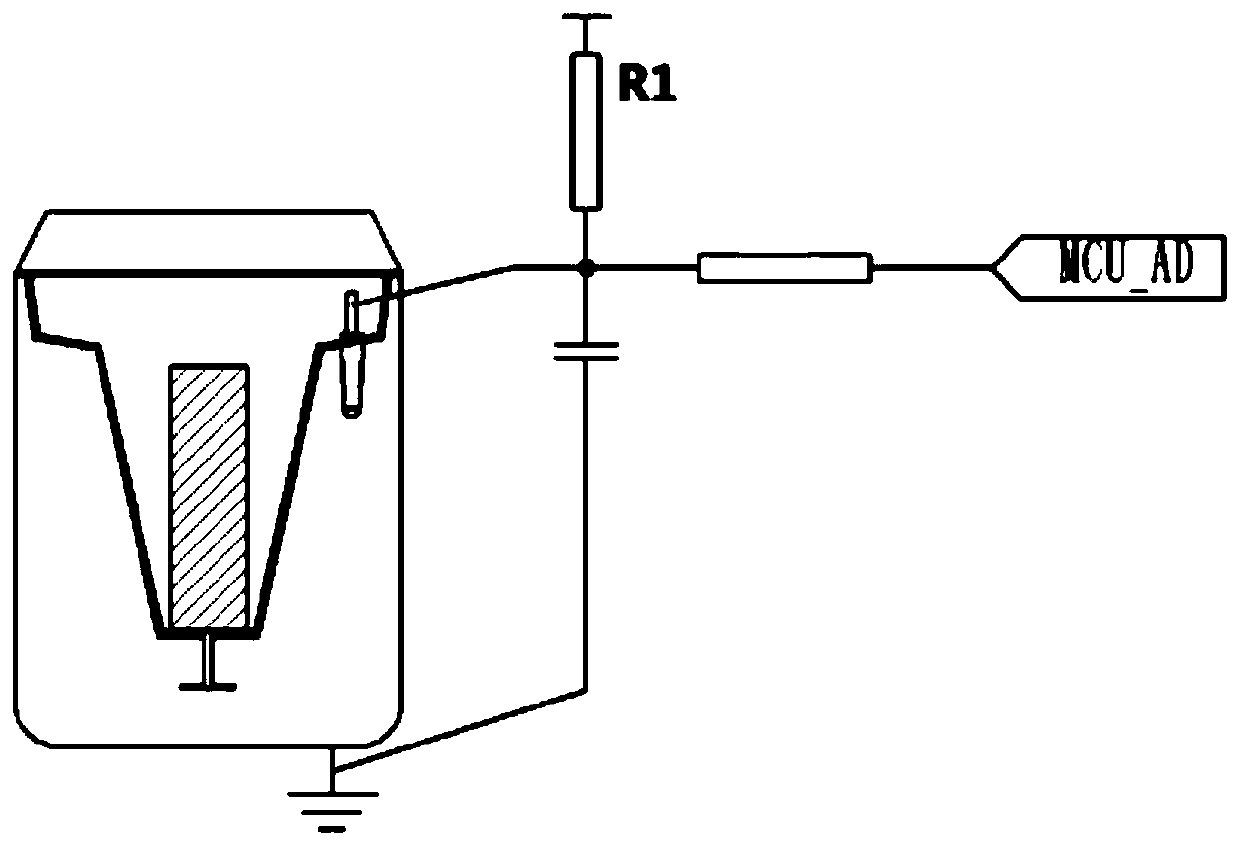

[0062] In the embodiment of the present invention, the installation structure diagram of the anti-overflow electrode is as follows figure 2 As shown, the anti-overflow electrode can be set on the top of the stirring chamber of a cooking device (such as a soymilk machine), the bottom of the stirring chamber is grounded, and there is a dielectric resistance R2 (not shown) between the anti-overflow electrode and the stirring chamber, pull up One end of the resistor R1 is connected to the power supply VCC, and the other end is connected to the overflow prevention electrode, and R1 and R2 form a voltage divider circuit. When the slurry in the stirring c...

Embodiment 2

[0105] The difference between this embodiment and the first embodiment is that a corresponding power adjustment scheme is adopted according to the judgment of the overflow and sticking state in the first embodiment.

[0106] Optionally, the method further includes: calculating the entire anti-overflow duration during the anti-overflow process, and adjusting the heating power according to the anti-overflow duration;

[0107] Among them, the anti-overflow duration includes:

[0108] The length of time to reach the overflow state directly, and,

[0109] The length of time to reach the stuck state and the length of time to reach the overflow state in the stuck state.

[0110] In the embodiment of the present invention, because of different working conditions (such as water level, amount of material, material type, voltage value, etc.), the originally set heating power may not be the best or the most suitable. The anti-overflow duration of the above-mentioned anti-overflow duration th is us...

Embodiment 3

[0119] The difference between this embodiment and the first embodiment is that the material judgment function is realized on the basis of the overflow prevention function realized by the overflow prevention electrode.

[0120] In the embodiment of the present invention, since the current distinction between beans and rice materials can only be distinguished by inputting function keys, it cannot be automatically determined. If the function keys do not correspond to the actual materials, it may cause abnormal performance and heating power. It cannot be adjusted according to the overflow prevention. For this reason, the embodiment of the present invention proposes a solution for judging whether the material is correct based on the voltage value on the anti-overflow electrode.

[0121] Optionally, the method further includes: pre-recording voltage reference values of different materials, and judging whether the current heating material is correct according to the detected voltage val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com