A Calculation Method of Particle Sliding Velocity in Pump Based on Clean Water Internal Flow Calculation

A technology of slip velocity and calculation method, which is applied in fluid velocity measurement, velocity/acceleration/impact measurement, instruments, etc., and can solve problems such as the slip velocity of particles in the pump that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

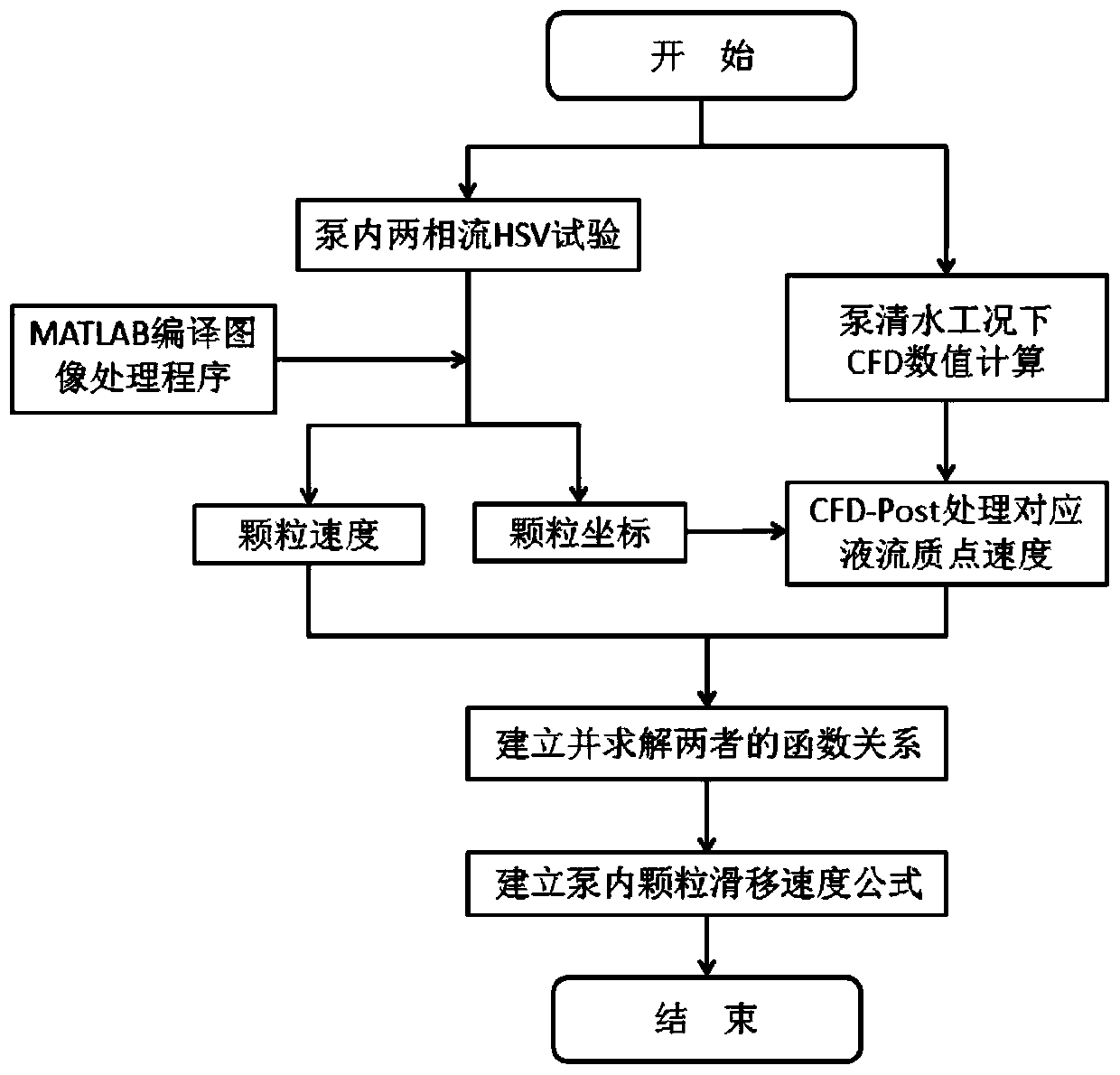

Method used

Image

Examples

Embodiment

[0034] A double-vane pump with a specific speed of 111, its design working condition: Q d =26m 3 / h, H=2.68m, n=750r / min.

[0035] Step 1. Use high-speed photogrammetry to measure the trajectory and velocity distribution of particles in the pump.

[0036] (1) Selection of measurement area and particles with different physical properties.

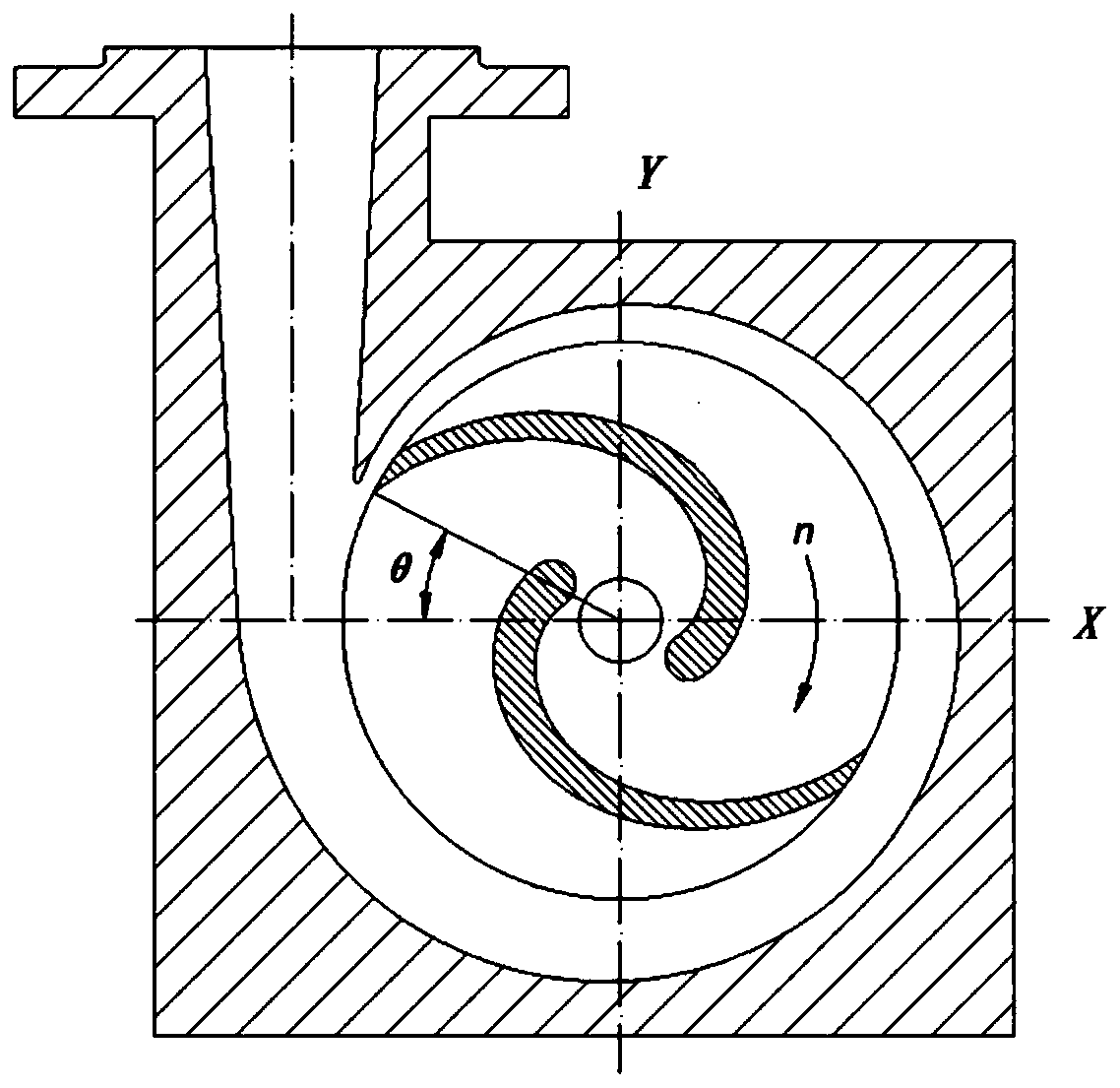

[0037] Select the middle section of the double vane pump as the measurement plane, such as figure 2 shown. The impeller rotates clockwise, and the angle between the suction surface of the blade facing the tongue and the X axis is θ=28°.

[0038] Select spherical rubber ball particles with a density slightly greater than that of fluid medium water, with a particle size of 12mm and a density of 1.09g / mm 3 , 1.2g / mm 3 , 1.75g / mm 3 .

[0039] (2) The measurement method of the velocity field in the pump.

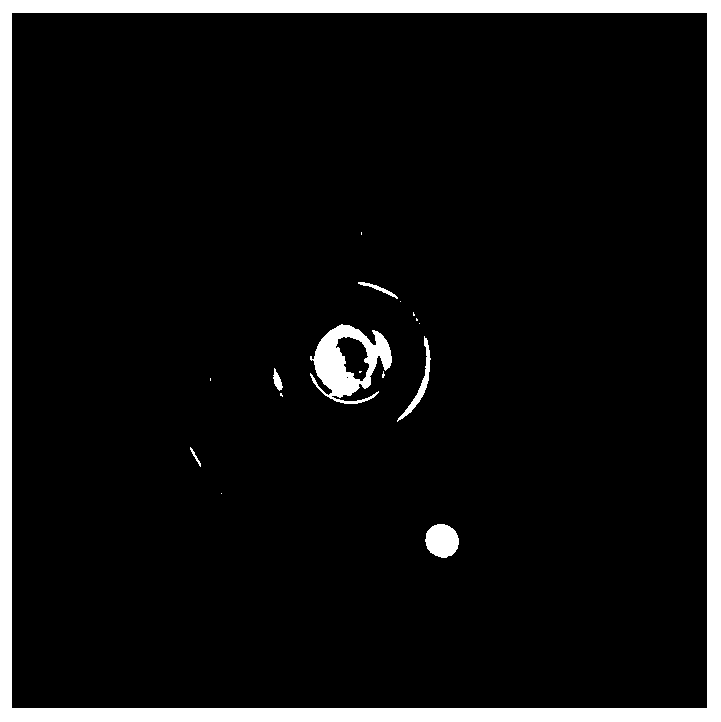

[0040] The particle motion in the pump is measured using the phase averaging method. The absolute velocity field of the two-phase f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com