Platform-based transformer lead wire manufacturing platform

A technology for manufacturing platforms and transformers, which is applied in the manufacture and connection of inductors/transformers/magnets, and circuit/collector components, etc. It can solve the problems of low safety factor in aerial work, cumbersome and time-consuming processes, and low production quality. Good performance, shortened installation time, standardized uniform cable length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

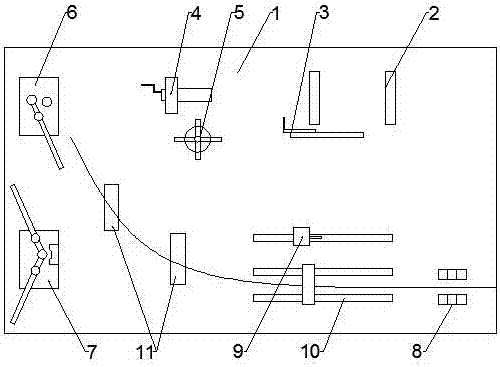

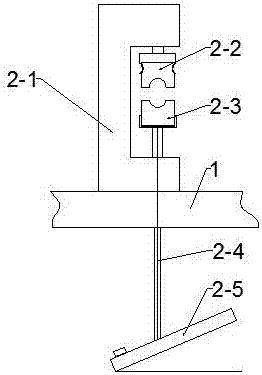

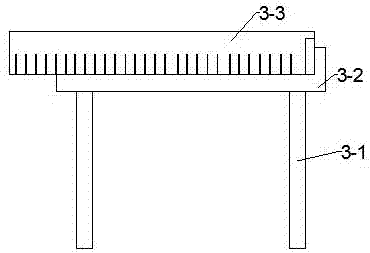

[0024] Such as Figure 1-9 As shown, a bench-type transformer lead wire manufacturing platform includes an operating platform 1, and an insulating layer stripping device, a wire binding manufacturing device, a wire radian manufacturing device, and an insulator and clamp assembly device are arranged on the operating platform 1; wherein, the insulating layer The stripping device includes a wire fixing bracket 2 and a moving ruler 3. The moving ruler 3 corresponds to the wire fixing bracket 2. The lead wire is fixed with the wire fixing bracket, and then the moving ruler is moved to mark the distance of the insulating layer to be stripped, and then the rotary stripping device is used. Wire pliers are used to strip the insulation layer to a fixed length. The binding wire making device comprises a binding wire winding device 4 and a binding wire seat 5, the binding line winding device 4 is fixedly connected with the operation platform 1, and the binding line seat 5 is movably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com