Injection molding piece die with inner thread and demoulding method thereof

A technology of injection molded parts and internal threads, which is applied in the field of injection molded parts molds and their demoulding, which can solve problems such as difficulty in improving demoulding efficiency, failure to achieve automatic demoulding effect, time-consuming and laborious demoulding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through a complete specific embodiment.

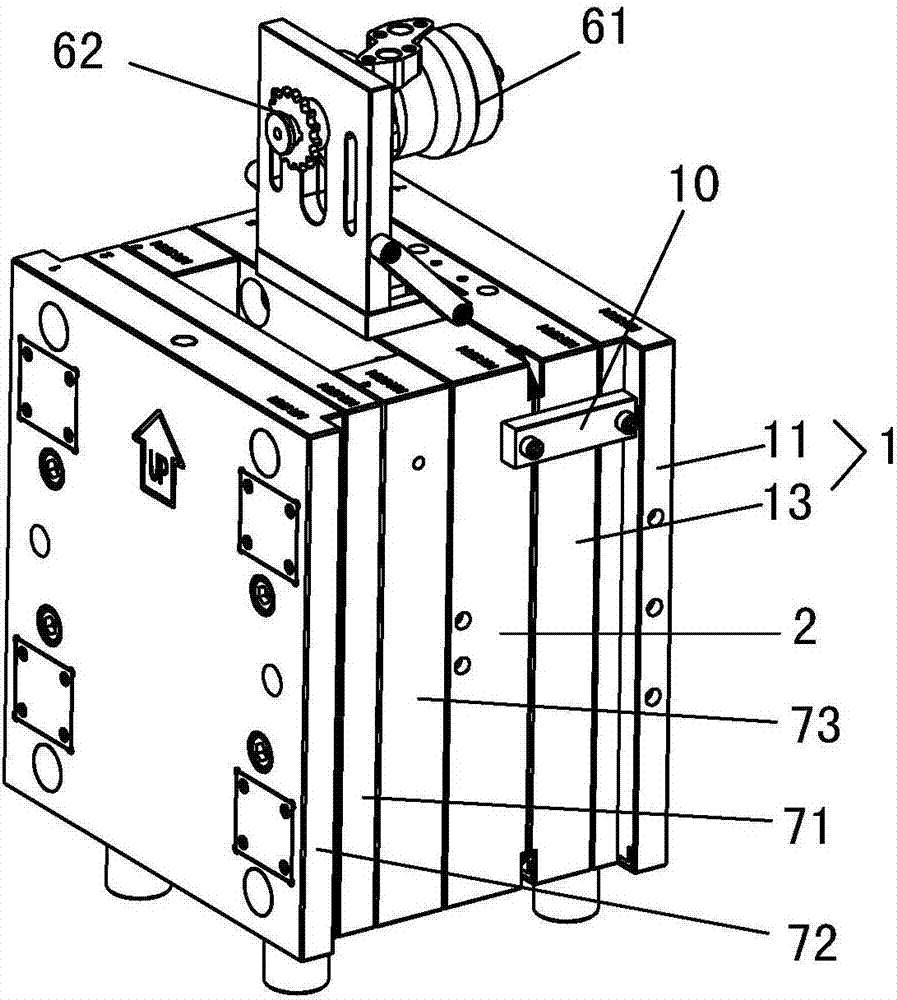

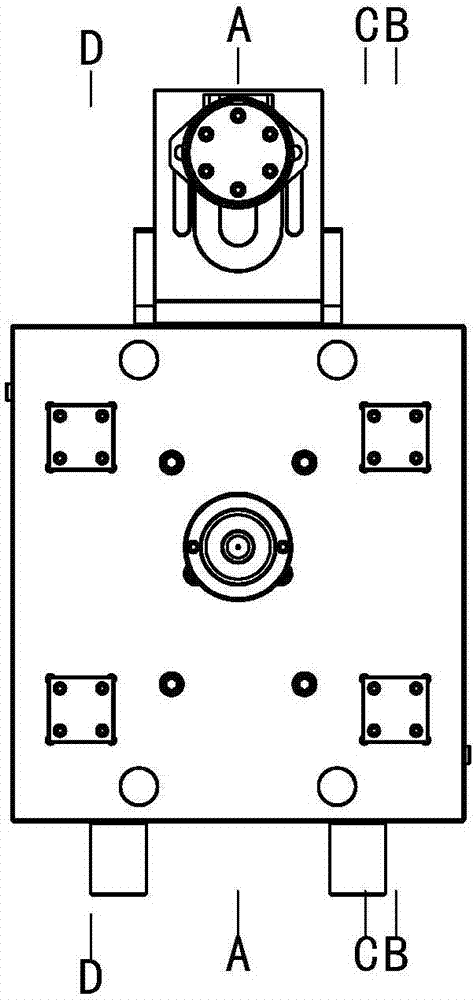

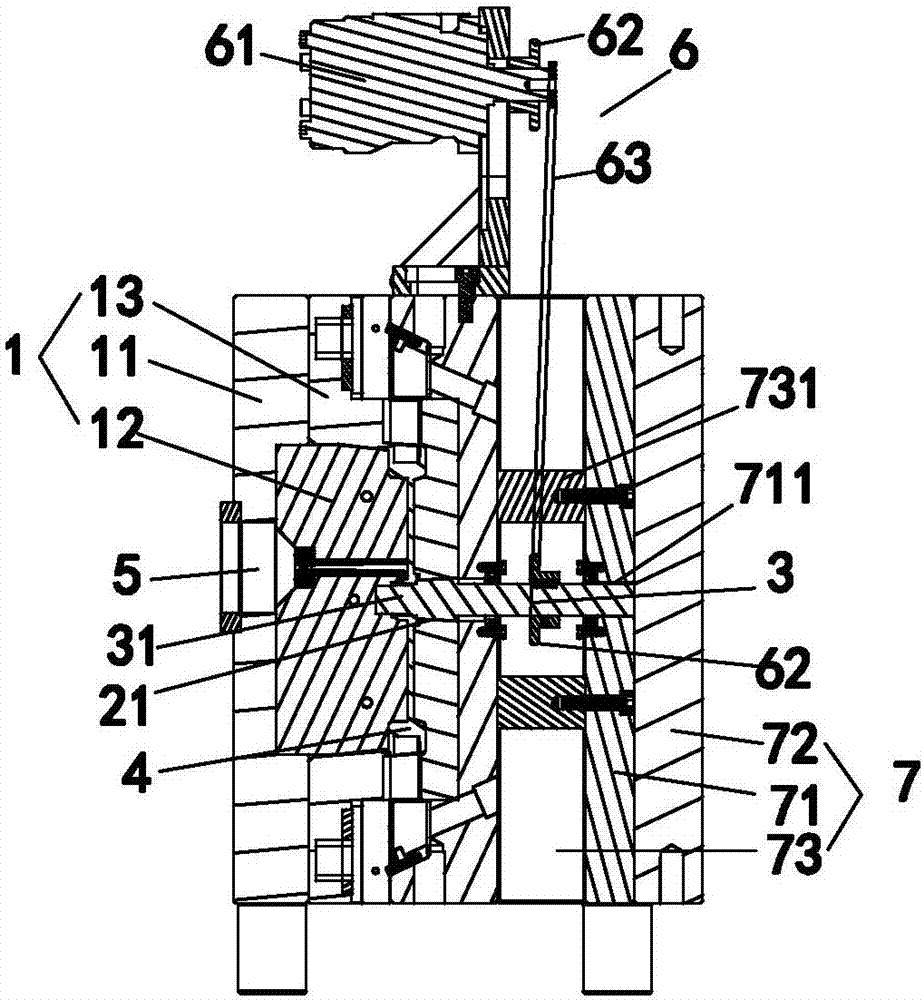

[0041] The injection mold of the tool internal thread disclosed by the present invention, such as Figure 1-6 As shown, it includes a first mold 1, a second mold 2 and a shaft 3, the second mold 2 is provided with a first through hole 21 matching the shaft 3, and the shaft 3 can rotate and slide through the Located in the first through hole 21, it can be set by a bearing. One end of the shaft 3 passes through the second mold 2 and is provided with a threaded core 31. The threaded core 31 is connected with the first mold 1 and the second mold. The molds 2 are combined to form the injection cavity 4 of the injection molded part. The first mold 1 or the second mold 2 is provided with an injection hole 5 leading to the injection cavity 4 , which is arranged on the first mold 1 in the figure. Let me ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com