Mold automatic demoulding structure

An automatic demoulding and mold technology, applied in the field of EPP mold automatic demoulding structure, can solve the problems of broken parts, unsafe, difficult demoulding, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

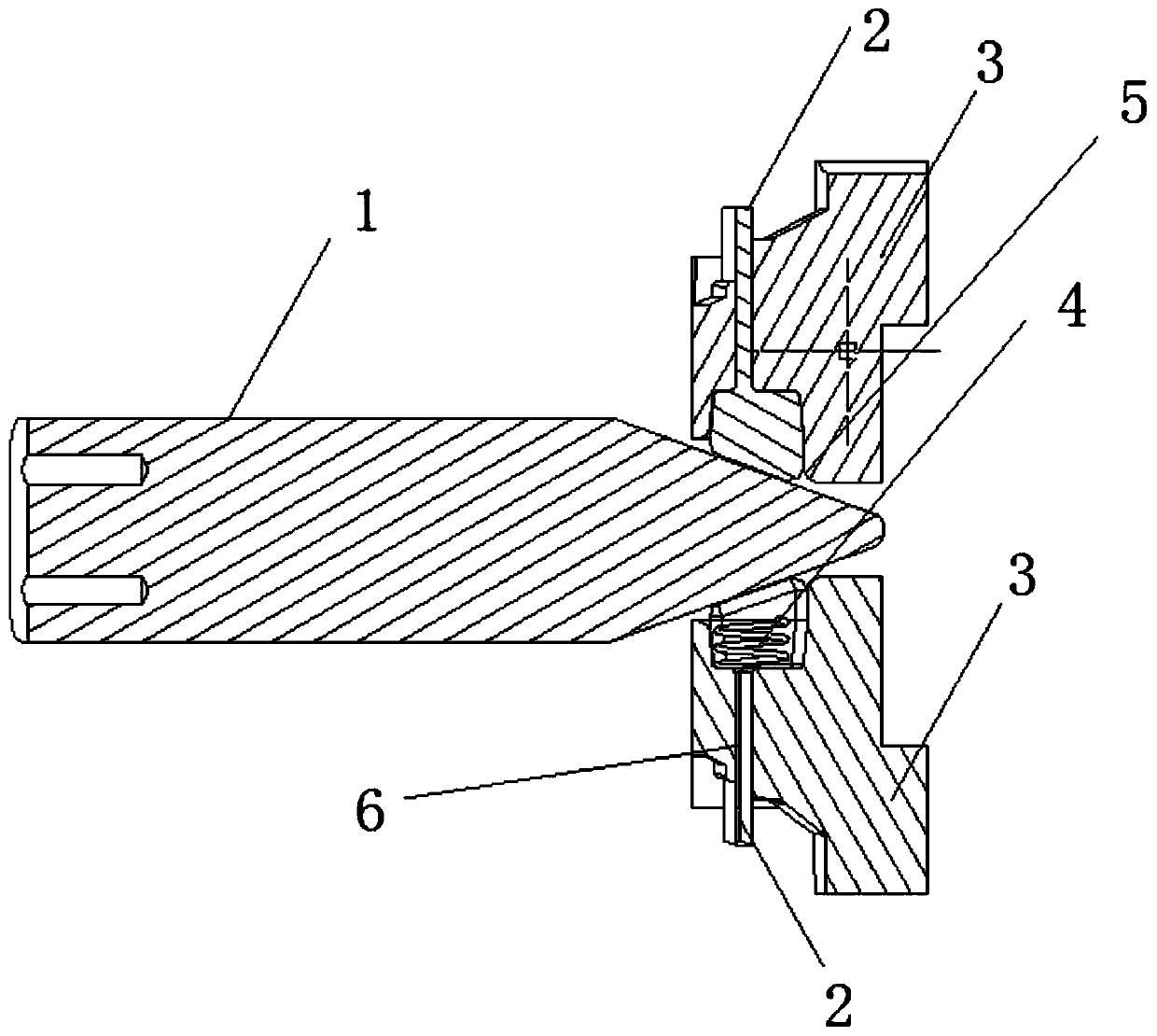

[0027] A kind of mold automatic demoulding structure, its structure sees figure 1 As shown, it is used to realize the demoulding of the mold of the molded part with an undercut structure, the mold includes a movable mold and a solid mold that match each other, and the automatic mold demoulding structure includes being installed in the cavity of the movable mold and following The movable mold pin 1 that moves together is provided with a mounting groove 5 on the base 3 of the solid mold at the position facing the bottom end of the movable mold pin 1 , and the side wall of the mounting groove 5 is processed with an outwardly extending and penetrating The chute 6 of the chute 6 is equipped with a fixed mold sliding block 2 sliding along it, and one end of the fixed mold sliding block 2 located in the installation groove 5 is the inner end, and the other end is the outer end, then the fixed mold sliding block 2 The end face of the inner end of the mold sliding block 2 is processed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com