Trolley with lifting and conveying functions

A technology of transmission function and trolley, which is applied in the field of trolleys, which can solve the problems of falling goods, inconvenience, and the need for manpower to carry, so as to achieve the effect of protecting heavy objects and facilitating manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

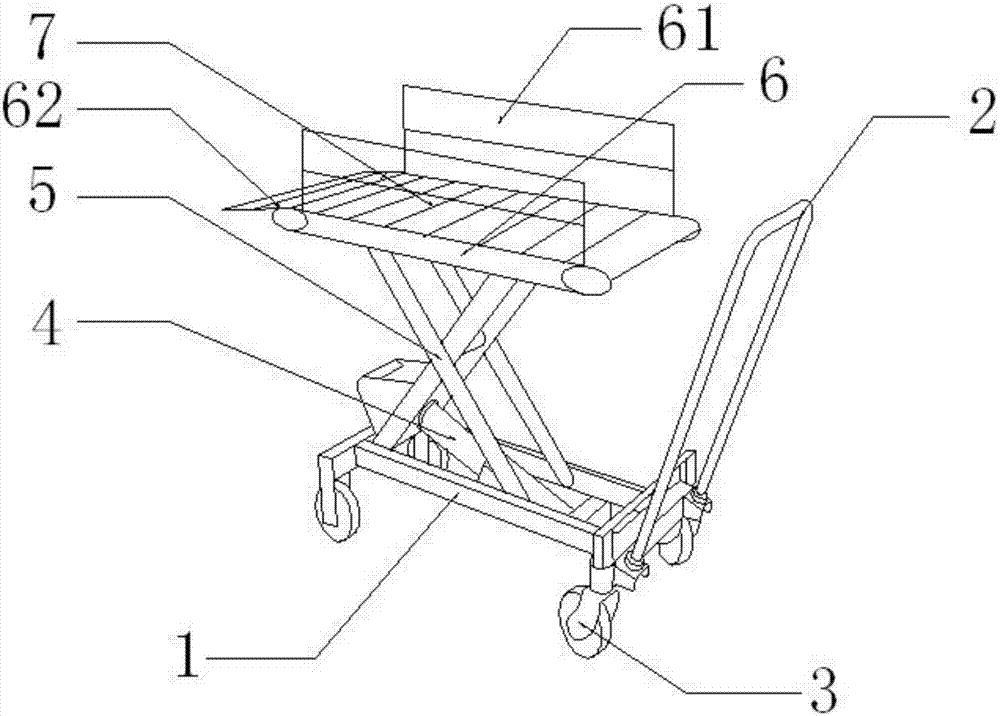

[0017] Such as figure 1 As shown, the trolley with lifting transmission function of the present invention includes a push handle 2 arranged on one side of the bottom frame 1, the bottom frame 1 is a rectangular structure, casters 3 are respectively installed on the four corners of the bottom frame 1, and the middle part of the bottom frame 1 A lifting device 4 is provided, and the lifting device 4 is connected with the support frame 5, and the support frame 5 is provided with a storage board 6, and a conveyor belt 7 is installed on the storage board 6, and the transmission direction of the conveyor belt 7 is opposite to the direction where the push handle 2 is located. Place the heavy object on the storage board 6, lift it to a required height by the lifting device 4, start the conveyor belt 7, and move the heavy object from the storage board 6 to the target area. The storage board 6 is provided with a baffle 61 , and the installation direction of the baffle 61 is the same as ...

Embodiment 2

[0019] Such as figure 1 As shown, the difference between this embodiment and Embodiment 1 is that the lifting device 4 includes a hydraulic cylinder, a lifting rod, a blocking head, and a slider. The rod cavity of the hydraulic cylinder is connected to the lifting rod, and the lifting rod is connected to the blocking The head is connected, and a slider is set under the blocking head, and the slider is set on the support frame 5. Through the pressure release of the hydraulic cylinder, the lifting rod is extended and retracted, and the blocking head is driven by the slider to move, and the lifting device 4 is lifted. at the predetermined height. Described caster 3 is swivel caster and fixed caster, and wherein two swivel wheels are installed on push handle 2 one side, and two fixed wheels are installed on push handle 2 side away from.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com