Con-focal laser measuring method

A laser measurement and confocal technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inconsistency and achieve the effect of measuring data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

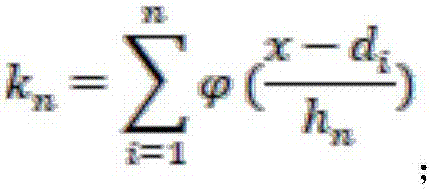

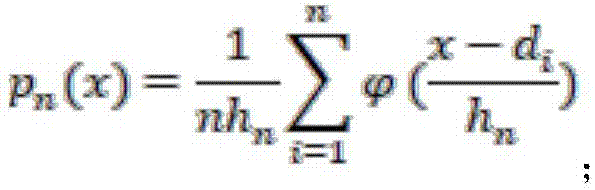

[0029] A confocal laser measurement method, the light beam is measured from the inside to the outside along the radius of the contact surface of the ball head, and is measured according to the step length of concentric circles with different radii, such as figure 1 As shown, a set of data is obtained: (x, y, depth), and a three-dimensional simulation diagram is drawn.

[0030] Further, the light beam is measured from the inside to the outside along the radius of the contact surface of the ball head, and is measured according to concentric circles with different radii to obtain a set of data: (x, y, depth) The specific operation steps are:

[0031] S1. Set the range of concentric circle radius r to [0, r], the origin coordinates (x, y) to (0, 0), and the sampling step to step;

[0032] S2. Calculating all the sampling radius lists radius;

[0033] S3. Add the origin to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com