Electric food processor

A conditioner and electric technology, applied in household appliances, applications, kitchen utensils, etc., can solve the problem of nutrient content reduction, achieve the effects of preventing reduction, reducing manufacturing costs, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

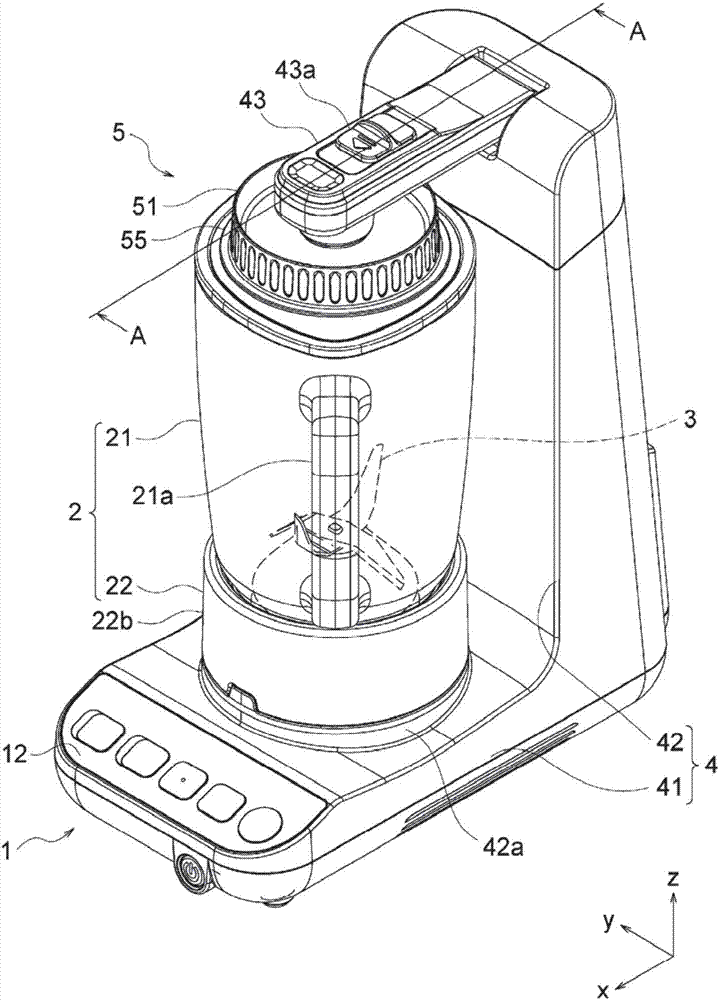

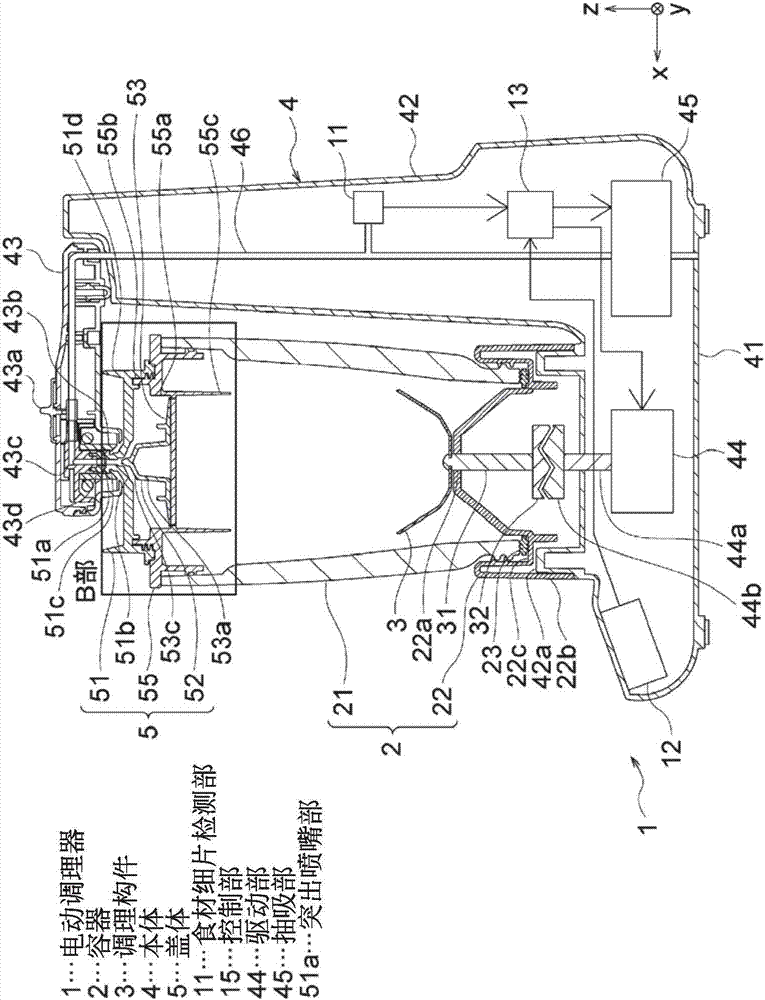

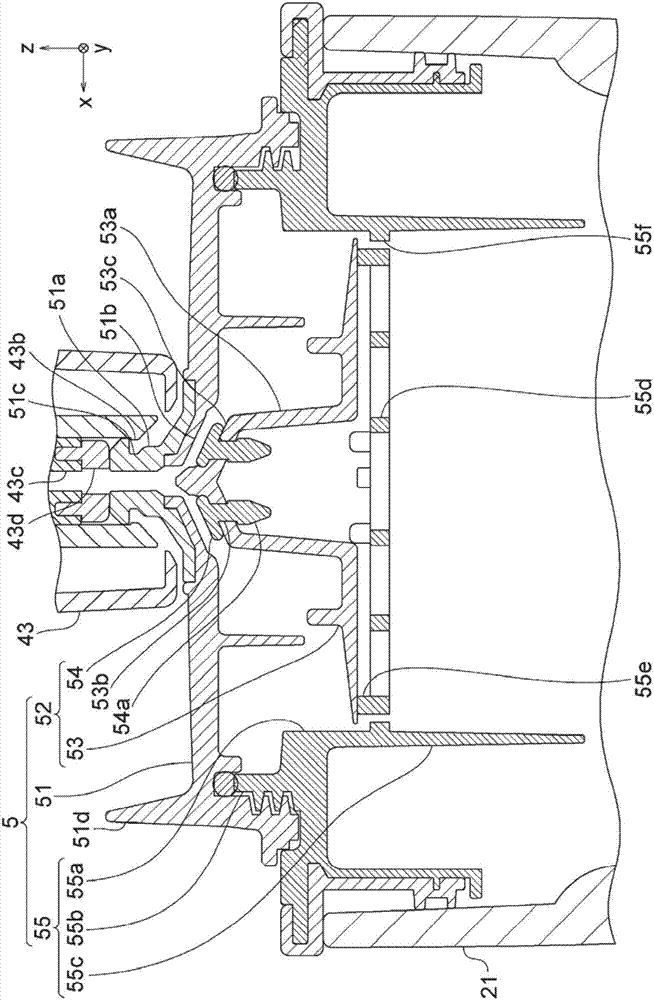

[0098] Hereinafter, an electric conditioner 1 according to a first embodiment of the present invention will be described with reference to the drawings.

[0099] figure 1 It is a perspective view of the electric conditioner 1 of the first embodiment, figure 2 for figure 1 The cross-sectional view seen when the A-A line is cut off, Figure 3A for will figure 2 A magnified view of part B in the magnification, Figure 3B for Figure 3A Enlarged view of closing the protruding nozzle part with the swing closing valve in Figure 4 for display figure 1 A perspective view of the cover body 5 in the electric conditioner 1, Figure 5 for will Figure 4 The expansion diagram that the cover body 5 is expanded, Figure 6 for display Figure 5 The oblique view of the rocking shut-off valve 52 in Figure 7 for will Figure 6 The expansion diagram that the rocking closing valve 52 is expanded, Figure 8 for display Figure 5 A perspective view of the lower side cover 55 in ...

no. 2 example

[0149] The electric conditioner 1' of the second embodiment is only different in the structure of the rotating connection part 43', the cover body 5' and the control part 13' of the first embodiment, so only these different structures will be described, and other structures will be described. Since it has the same structure as that of the first embodiment, its description will be omitted.

[0150] In addition, the coordinate system is the same coordinate system as that of the first embodiment.

[0151] Figure 11 It is a schematic sectional view of the electric conditioner 1' of the second embodiment.

[0152] The base end of the pivot connection portion 43' is rotatably pivotally supported, and an engaging claw 43b is formed on the front end side to move in conjunction with the operation lever 43a. The engaging claw 43b is formed so that according to the user's operation on the operation lever 43a, the engaging claw 43b is engaged with the protruding nozzle portion 51a desc...

no. 3 example

[0165] The electric conditioner 1" of the third embodiment is only different in the structure of the rotating connection part 43', the cover body 5' and the control part 13' of the second embodiment, so only these different structures will be described, and other structures will be described. Since it has the same structure as that of the first embodiment, its description will be omitted.

[0166] In addition, the coordinates are the same coordinate system as that of the first embodiment.

[0167] Figure 12 It is a schematic sectional view of the electric conditioner 1" of the third embodiment.

[0168] Such as Figure 12As shown, the cover body 5 "has: an upper side cover body 51" that is connected to the rotating connection portion 43 "and formed with a protruding nozzle portion 51a as the suction port of the suction portion 45; and the opening end of the container body 21 Fitted underside cover 55". The cover 5" is made of, for example, a resin material.

[0169] Such...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap