Device for lifting articles bound together by a strapping device

A technology for bundling devices and articles, which is applied to the device field of articles, can solve problems such as the structural complexity of hooking cranes, and achieve the effect of simplifying the lifting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

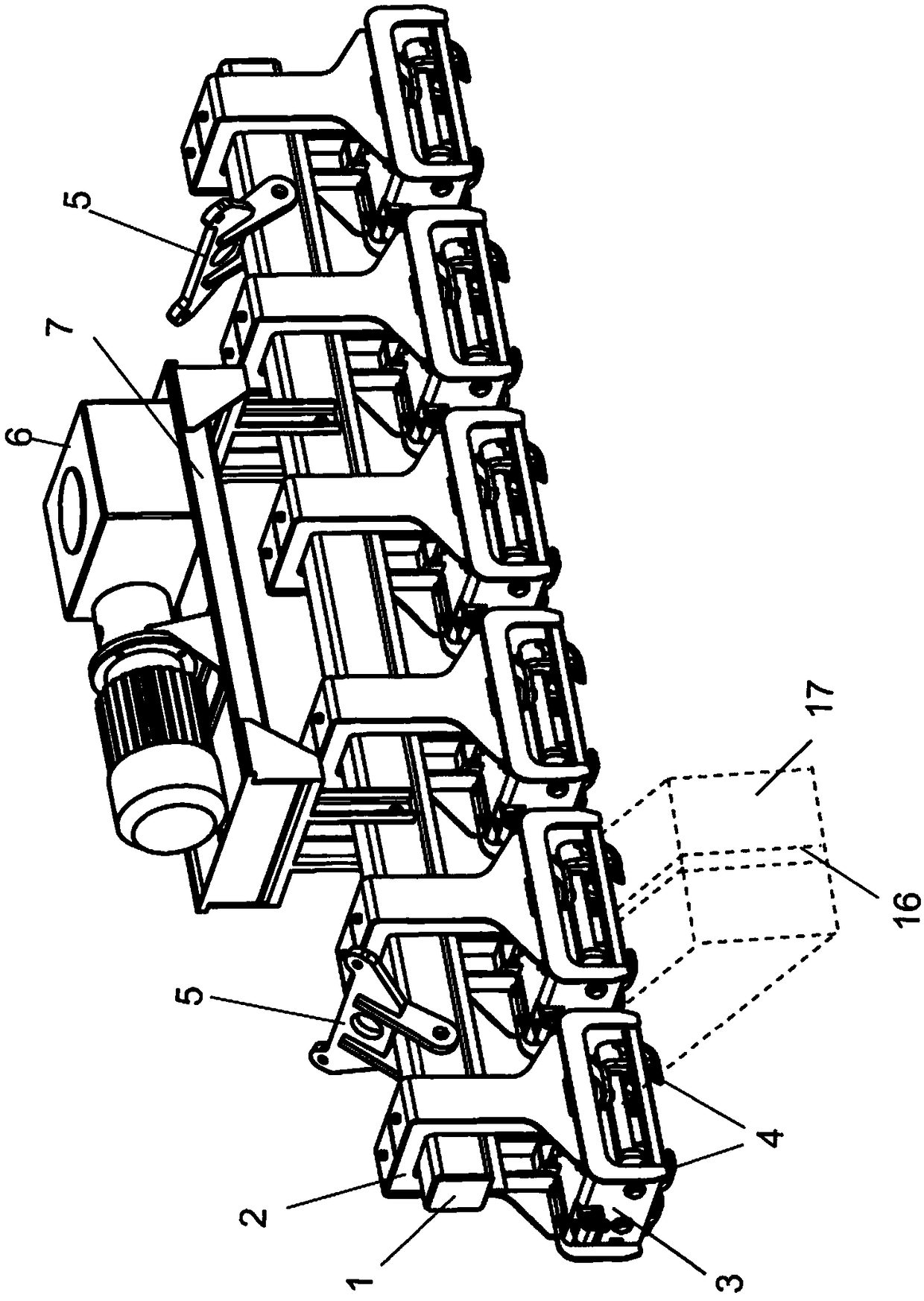

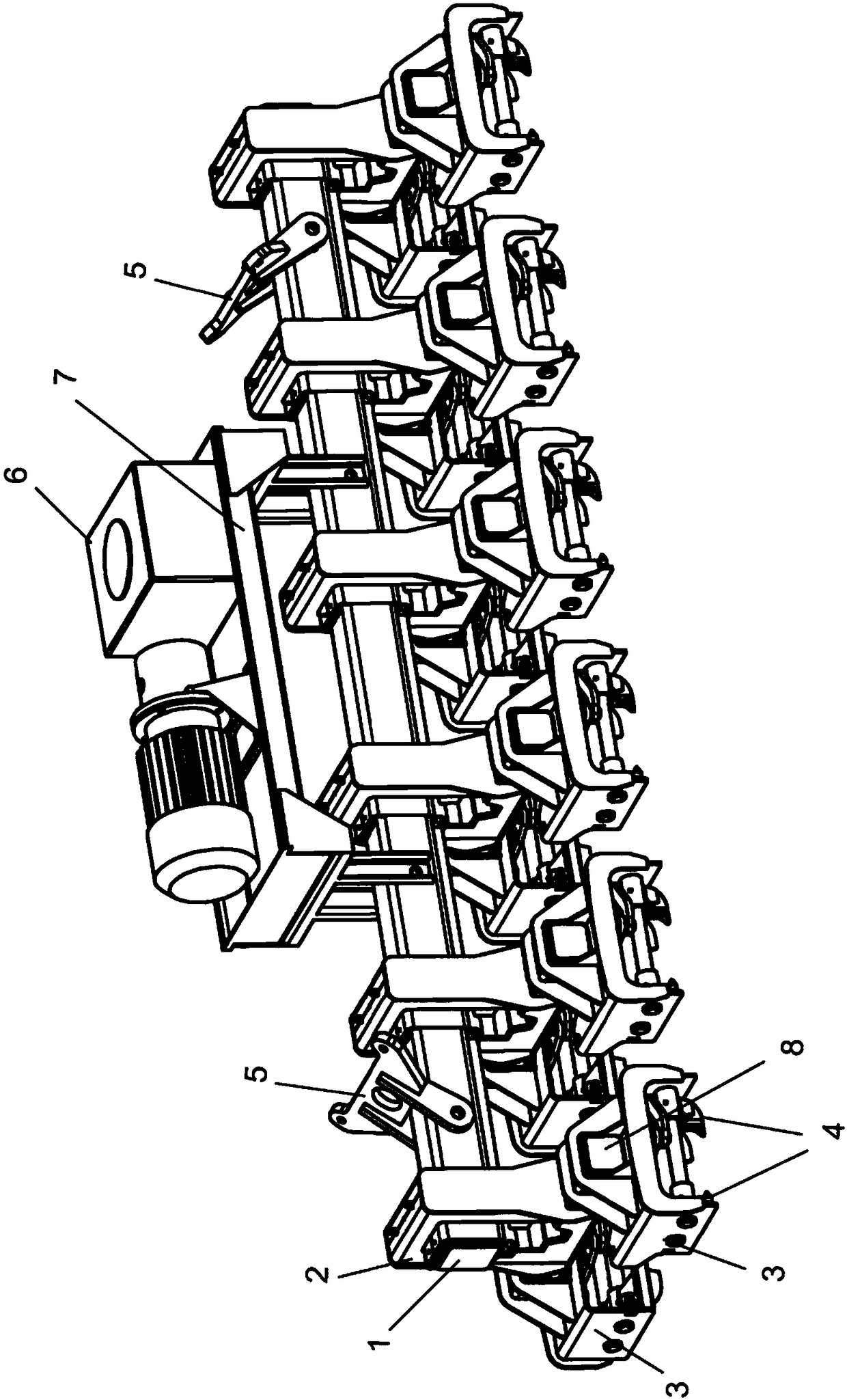

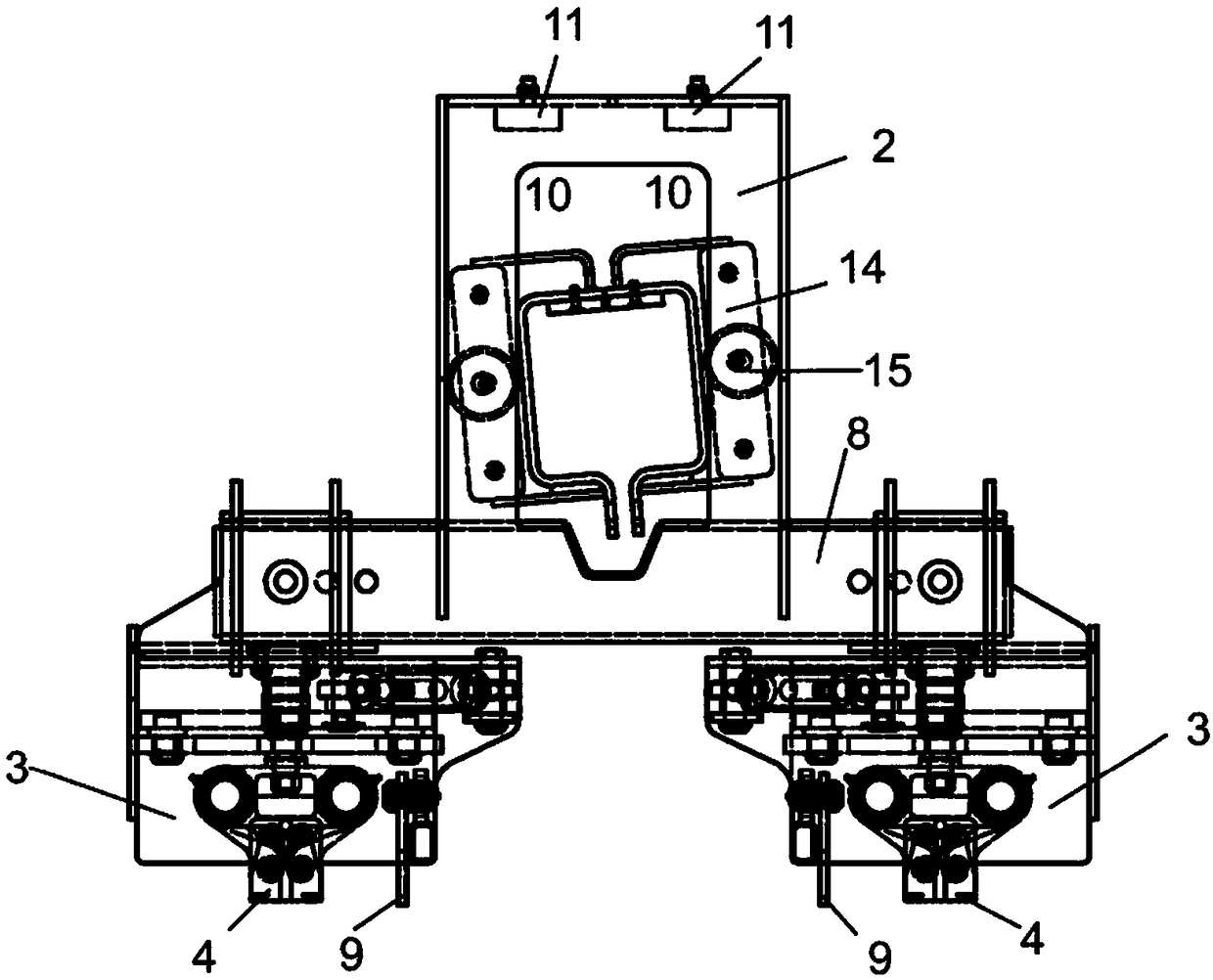

[0015] figure 1 Shown are hook trolleys 3 placed on the horizontal beam 1 of the lifting device, each hook trolley each comprising two gripping member pairs 4 at a distance from each other. This distance may even be as small as 30% of the width of the raised pulp unit 17, ie as small as 30% of the length of the sling / wire 16 on the top surface portion of the pulp unit. This makes it possible to provide a narrower and at the same time lighter hitch crane 3 . The hook crane 3 is suspended on the horizontal beam 1 by the groove member 2, and the horizontal beam 1 can move in the vertical direction in the groove gap and can also tilt therein. The hitch trolley 3 can be moved along the horizontal beam 1 in a manner known per se by means of moving means, such as hydraulic cylinders or electric drives, arranged on the bottom surface of the horizontal beam 1 . The gripping member 4 is also moved by means of moving means such as hydraulic cylinders or electric drives. figure 1 The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com