Overlay error measuring device and method

A technology of overlay error and measuring device, which is applied in the field of integrated circuit manufacturing and can solve problems such as influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

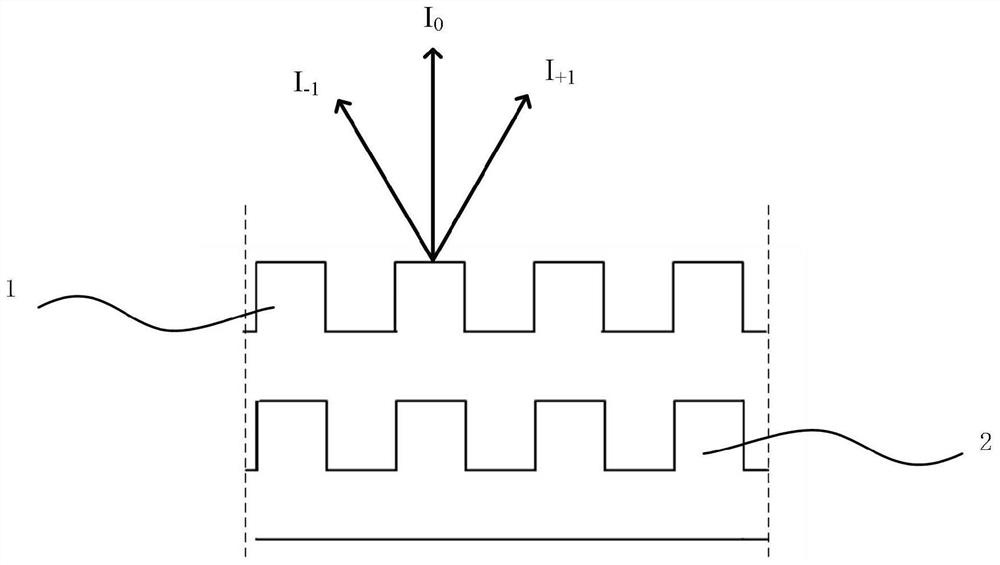

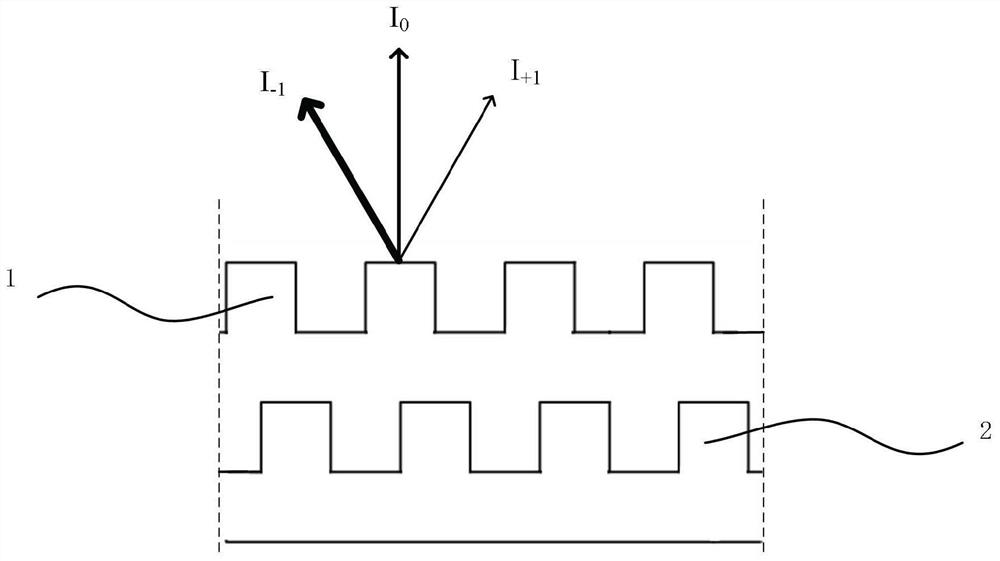

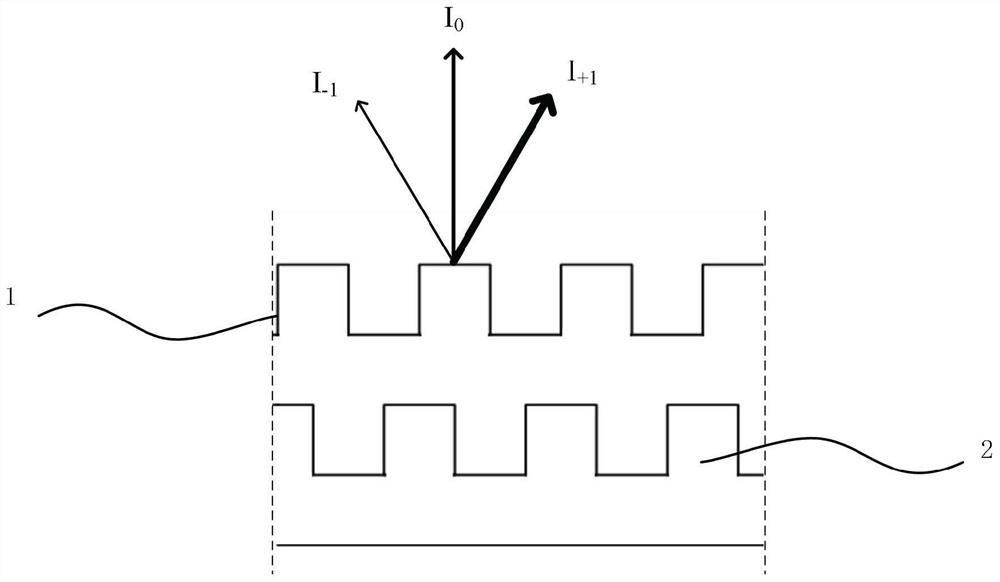

[0077] As mentioned above, in the commonly used devices or methods for measuring overlay errors, the influence of the non-uniformity of the measurement illumination spot itself on the overlay error is often ignored, or the calibration overlay mark is moved to make it located at the multi-point of the measurement illumination spot. The system is calibrated according to the sample measurement results at different positions, but due to too little sampled data, the characteristics of the marks used for calibration are not easy to control, and the calibration effect for the unevenness of the illumination spot itself is not good, and the calibration process is complex and time-consuming very long.

[0078] Therefore, there is a need for an overlay error measurement device and method that can achieve more accurate calibration of the non-uniformity of the measured illumination spot itself, thereby improving the detection performance of the photolithography machine and obtaining a more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com