Metal rectangular rounded-corner/non-rounded-corner straight wave rolling device

A rectangular and rounded technology is applied in the field of metal bellows sheet pressure wave processing devices, which can solve the problems of low efficiency and complex process of large-scale metal bellows, so as to achieve improved work efficiency, simple and easy production process, and stable shape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution will be described in detail below through a best embodiment, but the protection scope of the present invention is not limited to the embodiment.

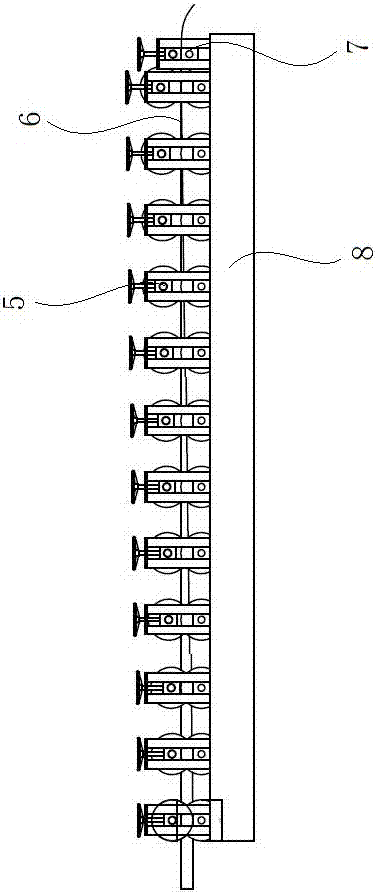

[0022] Such as figure 1 As shown, the metal rectangular rounded corner / non-rounded straight wave rolling device includes a pre-pressed plate 6, a guide device 7 and several corrugated pressing devices 5, and the guide device 7 and the corrugated pressing device 5 The boards are on the same horizontal plane and aligned. The pre-pressed plate 6 passes through the guide device 7 and several corrugated pressing devices 5 in sequence. A pre-flattening and straightening mechanism is provided on the guide device 7 .

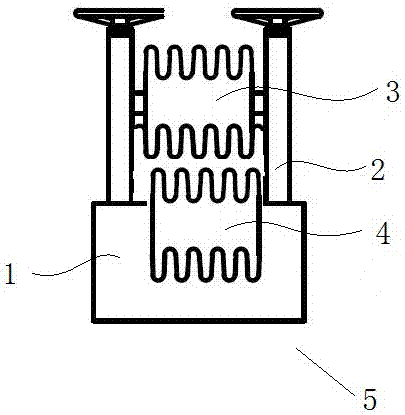

[0023] Such as figure 2 As shown, the corrugated pressing device 5 in the present invention includes a traveling console 1, two vertical pillars 2, an upper shaping gear 3, and a shaping gear 4. The two vertical pillars 2 are arranged on both sides of the traveling console 1, so that The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com