Rolling brush component with height capable of being accurately adjusted

A technology of height adjustment mechanism and roller brush, applied in the direction of using tools for cleaning, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of large adjustment gap, difficulty in ensuring accuracy, and inability to adjust the non-operating side independently. To achieve the effect of synchronous precise adjustment and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

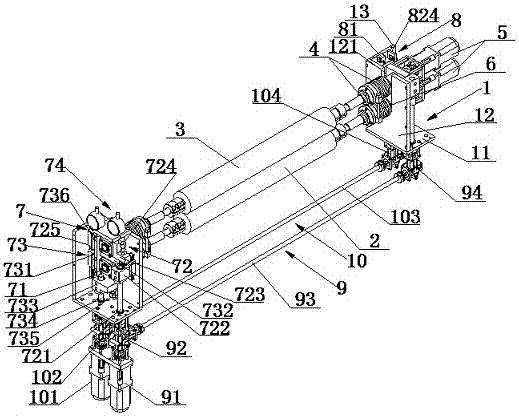

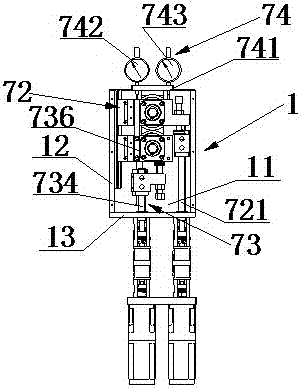

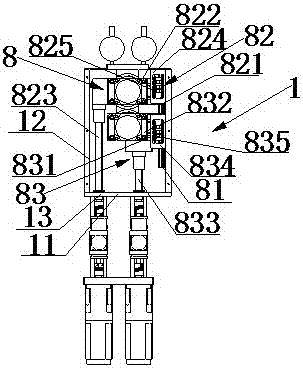

[0027] Such as Figure 1 to Figure 3 The height-adjustable roller brush assembly shown mainly includes a support frame 1, a lower roller brush 2, an upper roller brush 3, a first height adjustment mechanism 7, a second height adjustment mechanism 8, a first synchronous lifting mechanism 9 and The second synchronous lifting mechanism 10 etc.

[0028] Wherein, there are two groups of supporting frames 1, which are arranged on the same horizontal plane and arranged at intervals; each group of supporting frames 1 includes a bottom mounting plate 11, a support vertical plate 12 fixed on the upper surface of the bottom mounting plate 11 and perpendicular to it, and a fixed On the upper surface of the bottom mounting plate 11 and the side plates 13 perpendicular to the bottom mounting plate 11 and the supporting vertical plate 12 respectively, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com