Chipless blanking device for copper pipe

A technology for equipment and copper tubes, applied in the field of copper tube chipless cutting equipment, can solve the problems of port burrs, broken copper chips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

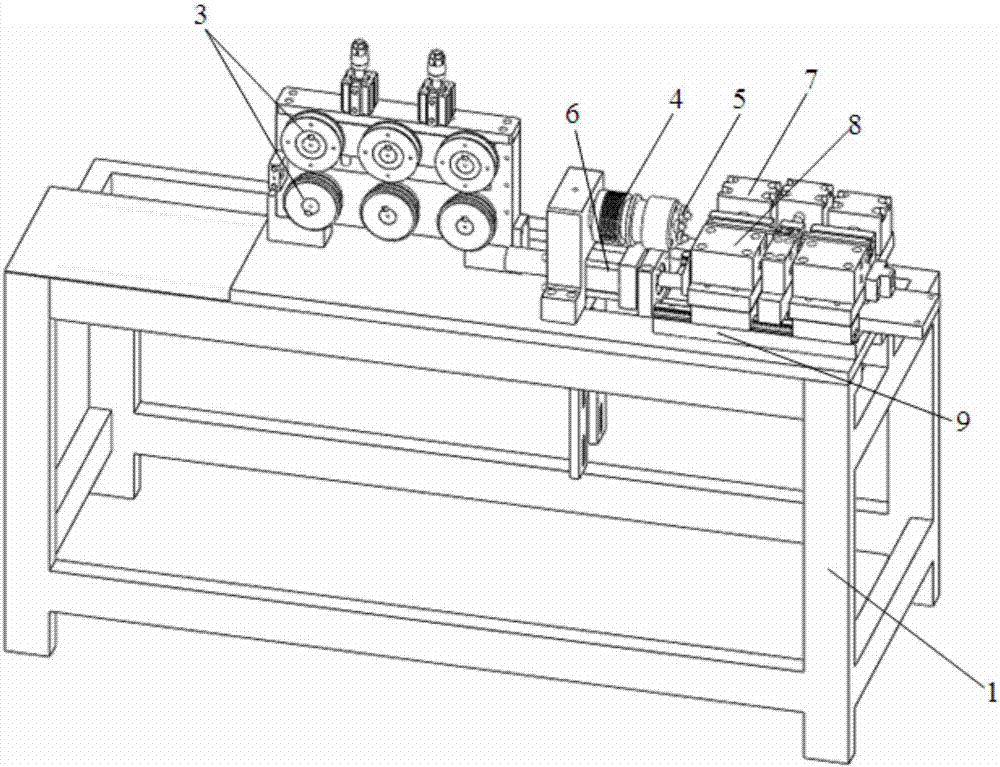

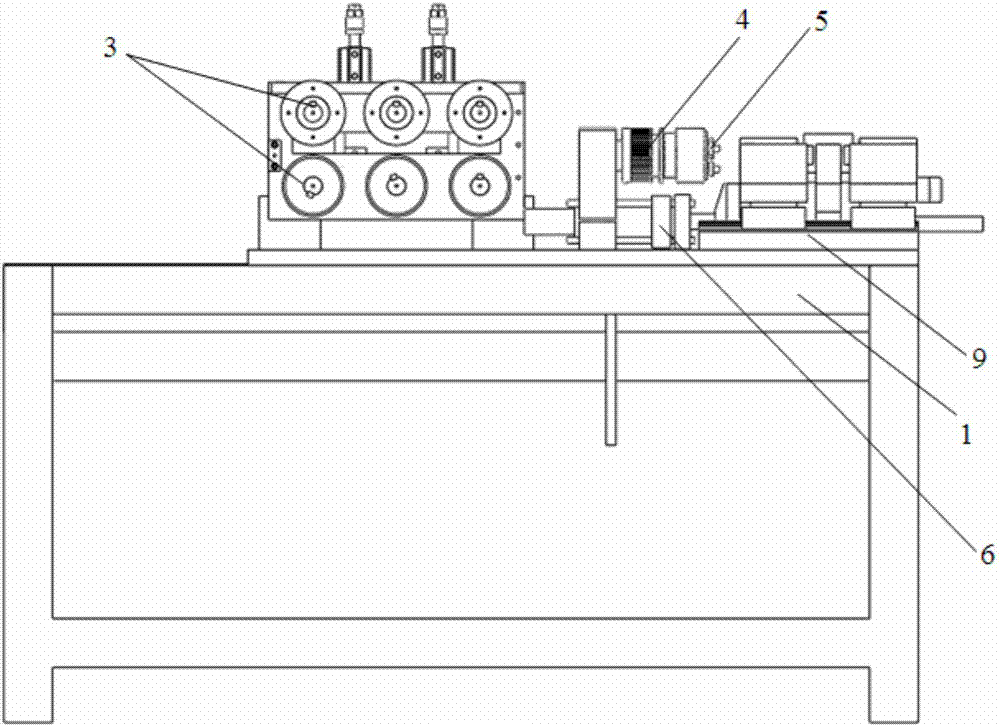

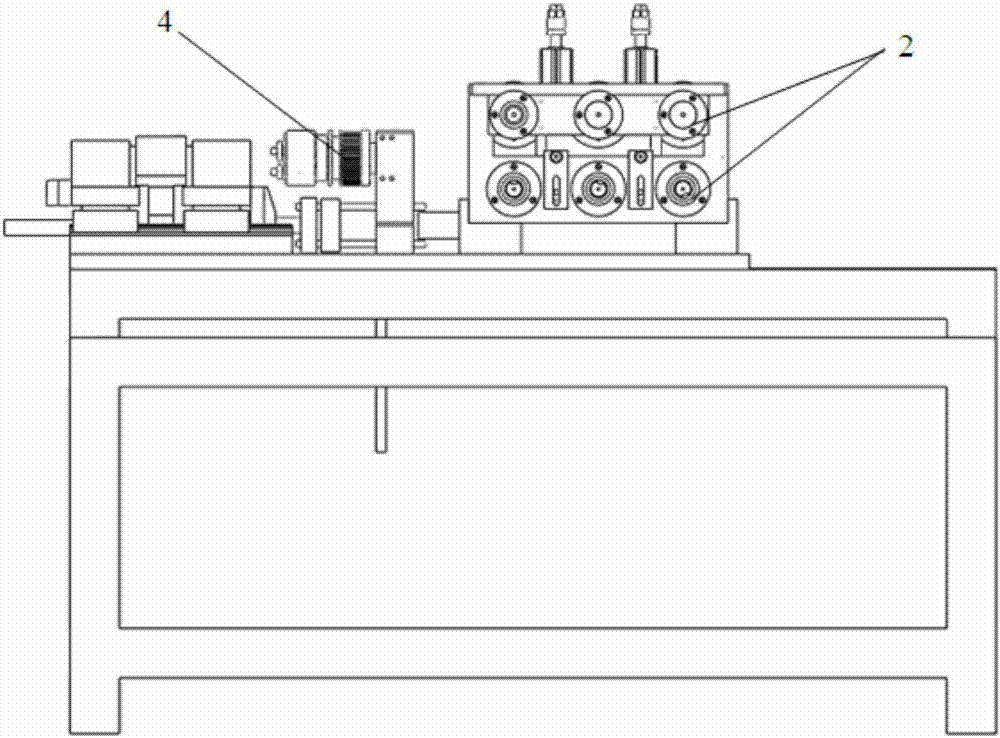

[0013] See attached Figure 1-5 As shown, a copper pipe chipless blanking equipment includes a frame 1 and a feeding mechanism, a chipless cutting mechanism and a breaking mechanism arranged on the frame 1 in turn. The feeding mechanism consists of a vertically symmetrical The stepper motor 2 drives the transmission wheel 3 which is connected with it and interlocks with each other to form, and the chipless cutting mechanism is formed by the motor 4 driving the cutter head 5 through the synchronous pulley; the breaking mechanism includes the first cylinder 6, the second Two air cylinders 7, clamps 8 and slide block 9, described slide block 9 is located on the described frame 1, and described first air cylinder 6 is connected with described slide block 9, and described clamp 8 is fixed on described slide block 9, the second cylinder 7 is connected to the clamp 8. The principle is: the copper pipe passes between the interlocking transmission wheels 3 of the feeding mechanism, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com