Ball poking device

A technology of picking the wheel and magazine, which is applied in the field of picking devices, which can solve the problems of inaccurate picking, loose structure, complex structure, etc., and achieve the effect of easy and convenient picking, ingenious design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

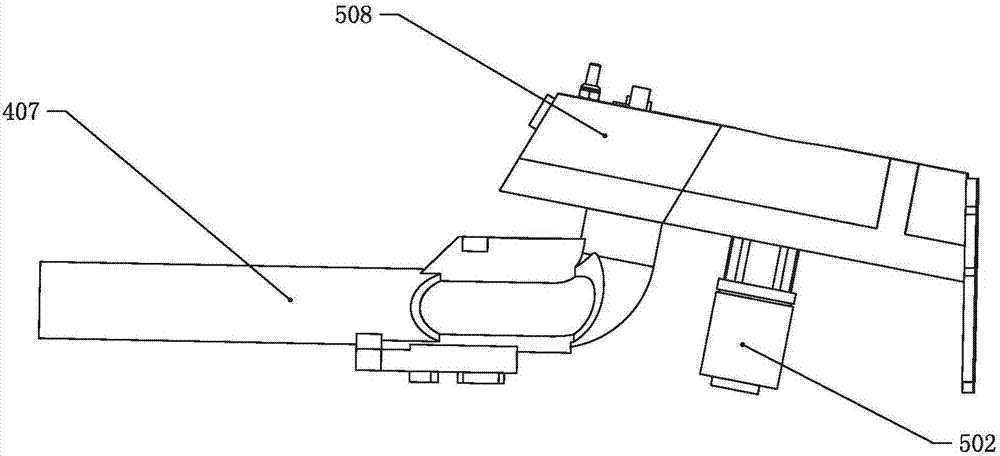

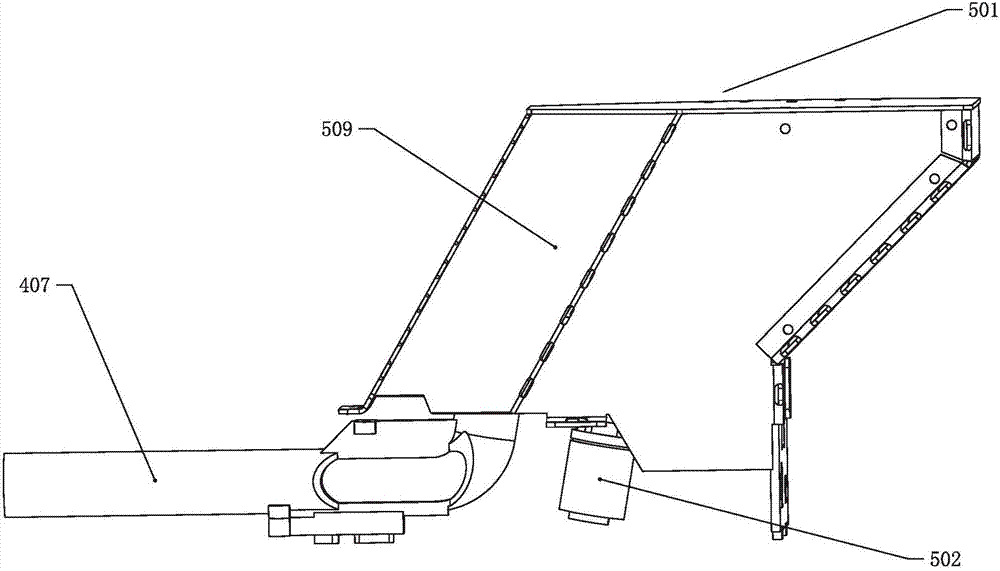

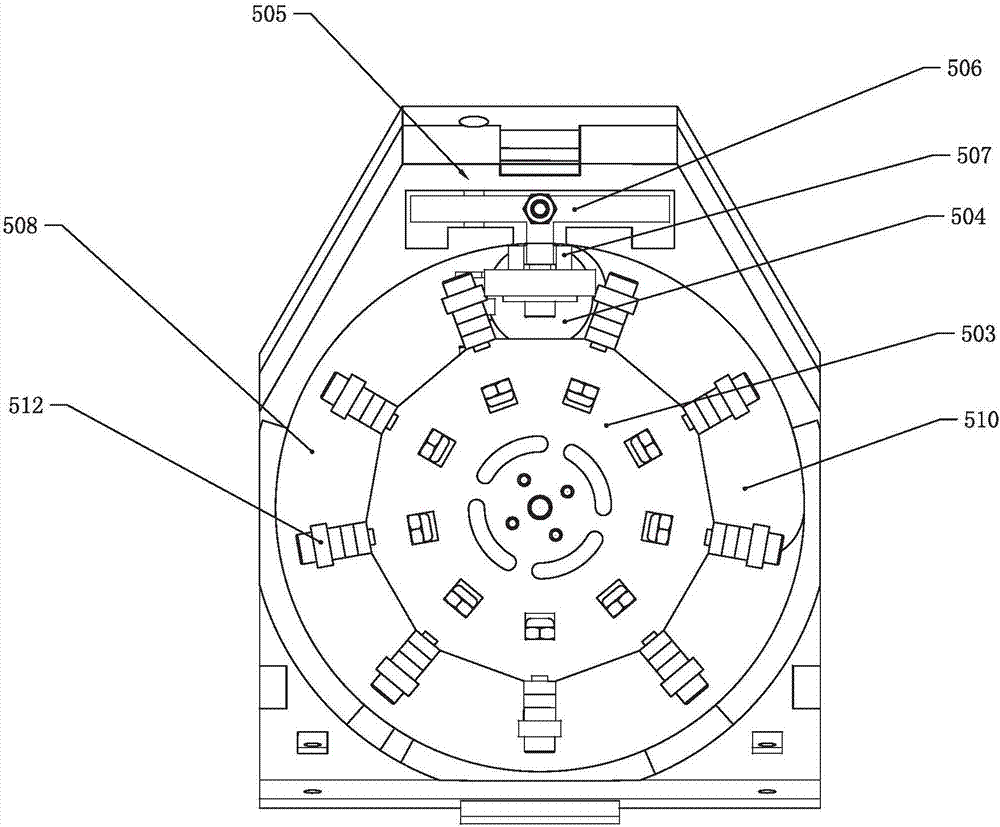

[0025] Such as Figure 1 to Figure 3 As shown, a kind of strumming device provided by the present invention includes a magazine 501, the bottom of the magazine 501 is an inclined bottom plate 508, a baffle plate 509 is provided around the bottom plate 508, and a bullet hole 504 is provided at the top of the bottom plate 508. , the bullet hole 504 is communicated with the material inlet of the launch tube 407, a bullet distributor 505 is installed above the bullet hole 504, and a rotatable dial wheel 503 is installed on the bottom of the base plate 508, and the magazine 501 is turned when the dial wheel 503 rotates. The spherical material in is transferred in the launch tube 407.

[0026] The bottom plate 508 is a circular structure surrounded by the baffle plate 509, the center of the circle of the bottom plate 508 coincides with the center of circl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com