Multi-fuel nozzle, fuel ejection system and turbine engine thereof

A multi-fuel and nozzle technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of single fuel for turbine engine nozzles, single fuel for turbine engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

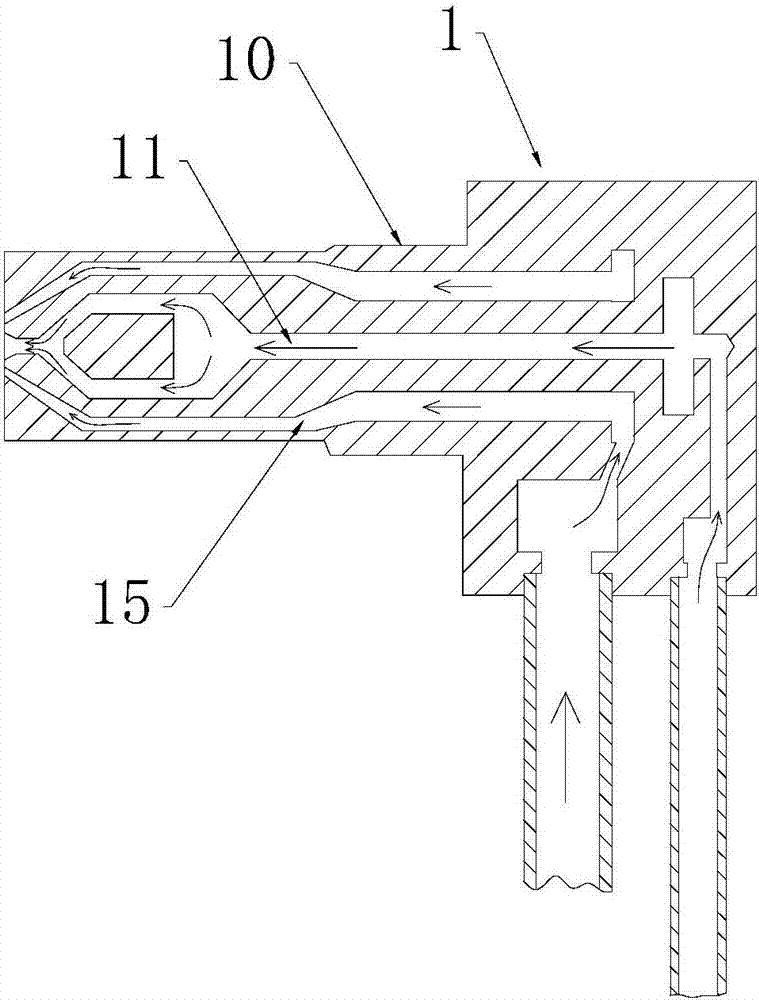

[0055] Such as figure 1 As shown, the multi-fuel nozzle 1 provided in this embodiment includes a nozzle body 10 in which a first fuel flow passage 11 and a second fuel flow passage 15 are provided. On a cross-section perpendicular to the fuel flow direction, The first fuel flow passage 11 is arranged in the middle, and several second fuel flow passages 15 are arranged in the circumferential direction of the first fuel flow passage 11.

[0056] A plurality of second fuel flow passages 15 are evenly arranged in the circumferential direction of the first fuel flow passage 11.

[0057] Among them, the number of the second fuel flow passage 15 is 3-20.

[0058] Preferably, the first fuel flow channel 11 has a narrower aperture at the end of its fuel injection. The second fuel flow path 15 narrows the aperture at the end of the fuel injection.

[0059] The second fuel flow passage 15 approaches the first fuel flow passage 11 in the radial direction of the nozzle body 10 at the end of the f...

Embodiment 2

[0064] The structure of this embodiment is basically the same as that of embodiment 1, and the difference lies in:

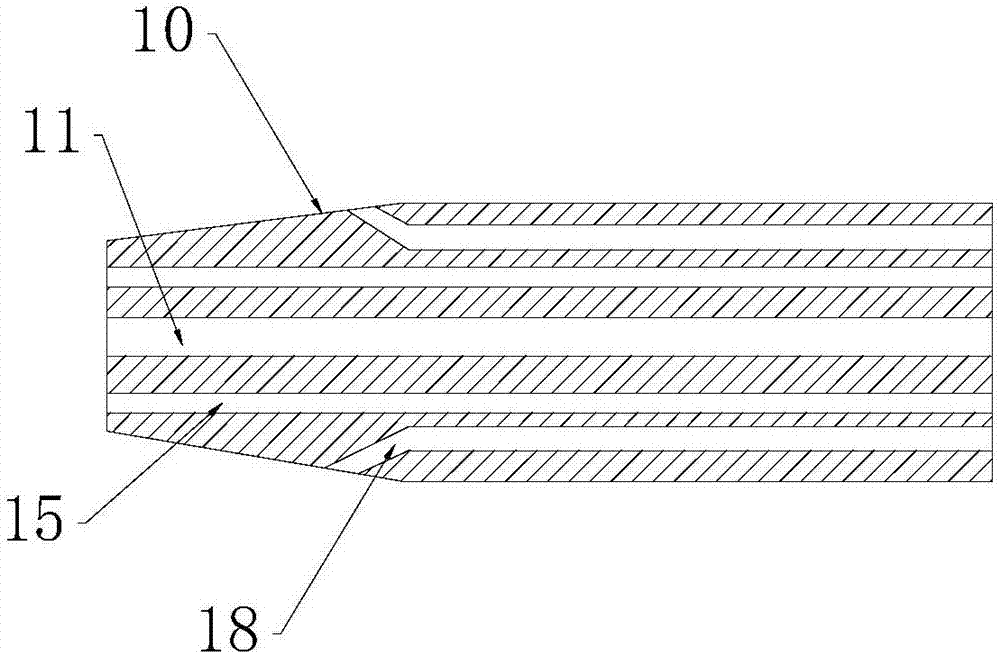

[0065] Such as figure 2 As shown, the nozzle body 10 is also provided with a number of third fuel flow passages 18, in a cross section perpendicular to the fuel flow direction, a number of third fuel flow passages 18 are provided in the circumferential direction of the first fuel flow passage 11, In the radial direction, the second fuel flow passage 15 is provided between the first fuel flow passage 11 and the third fuel flow passage 18.

[0066] That is, on a cross-section perpendicular to the fuel flow direction, the first fuel flow channel 11, the second fuel flow channel 15 and the third fuel flow channel 18 are sequentially arranged from the inside to the outside.

[0067] The third fuel flow path 18 is away from the first fuel flow path 11 outward in the radial direction of the nozzle body 10 at the end of the fuel injection. That is, the fuel outlet of the thi...

Embodiment 3

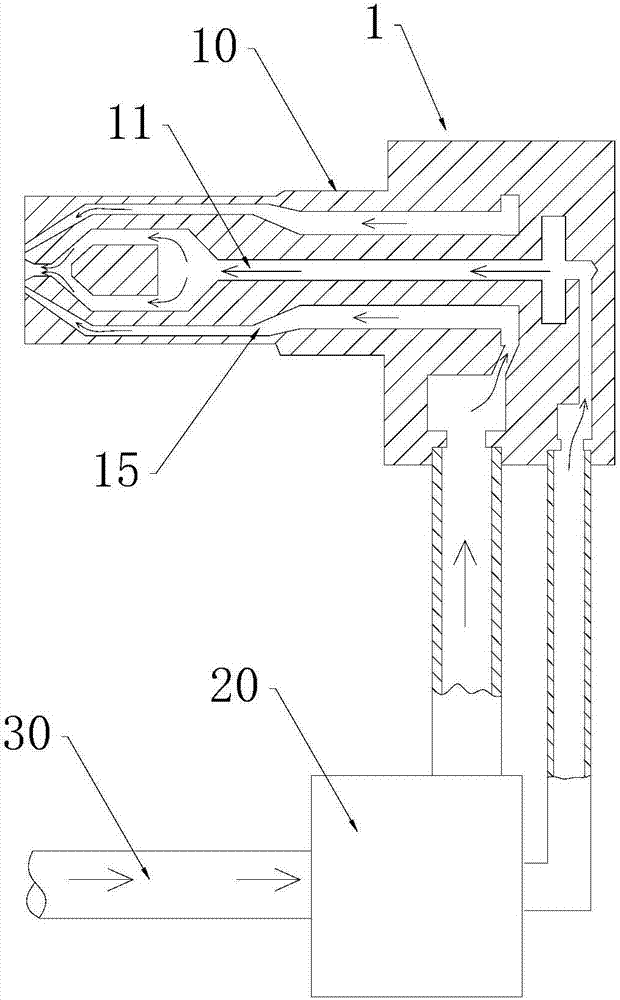

[0070] Such as image 3 As shown, the embodiment of the present invention also discloses a fuel injection system using the above-mentioned multi-fuel nozzle 1, which further includes: a fuel supply pipe 30 and a fluid distribution device 20;

[0071] The fuel supply pipeline 30 is connected to the multi-fuel nozzle 1 through the fluid distribution device 20;

[0072] The fluid distribution device 20 is used to split the fuel from the fuel supply line 30 into the first fuel flow passage 11 and the second fuel flow passage 15.

[0073] A regulating valve (not shown) is provided in the fluid distribution device 20 for dividing or proportionally distributing the fuel from the fuel supply line 30 to the first fuel flow passage 11 and the second fuel flow passage 15.

[0074] By controlling and adjusting the regulating valve on the fluid distribution device 20, all the fuel from the fuel supply pipe 30 can be diverted to the first fuel flow passage 11 or the second fuel flow passage 15, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com