Novel micro channel evaporator

A micro-channel, evaporator technology, applied in evaporator/condenser, refrigeration components, refrigerators, etc., to achieve the effect of balanced pressure distribution, balanced distribution of working fluid, and improved heat exchange performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific embodiment and accompanying drawing, set forth more details in the following description so as to fully understand the present invention, but the present invention can be implemented in a variety of other modes different from this description obviously, Those skilled in the art can make similar promotions and deductions based on actual application situations without violating the connotation of the present invention, so the content of this specific embodiment should not limit the scope of protection of the present invention.

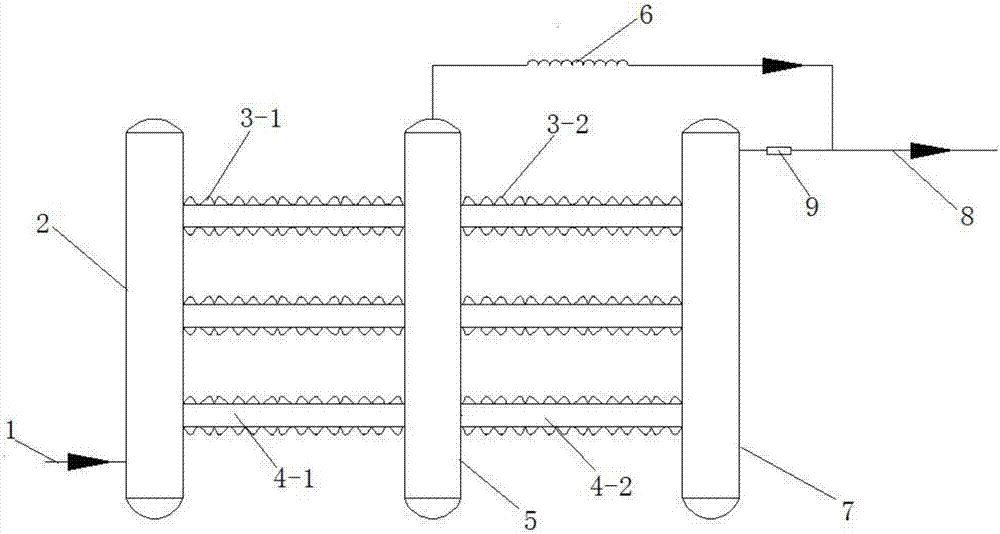

[0012] Such as figure 1 As shown, a new microchannel heat exchanger consists of a working fluid inlet header 2, an intermediate gas-liquid separation header 5, a working fluid outlet header 7, several flat tubes with fins, and a capillary tube. A viewing mirror constitutes. One end of the working fluid inlet header is the working fluid inlet 1, the working fluid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com