Stern shaft seal gland for high speed ship

A sealing device and stern shaft technology, which is applied to the sealing of the engine, the transmission device using synchronous propulsion components, the water acting propulsion element, etc., can solve the problem of increasing the complexity of the management personnel's work, severe wear of the stern shaft, and large shaft power loss, etc. problems, to avoid pollution and rust in the cabin, high quality and cost-effective, and reduce shaft power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

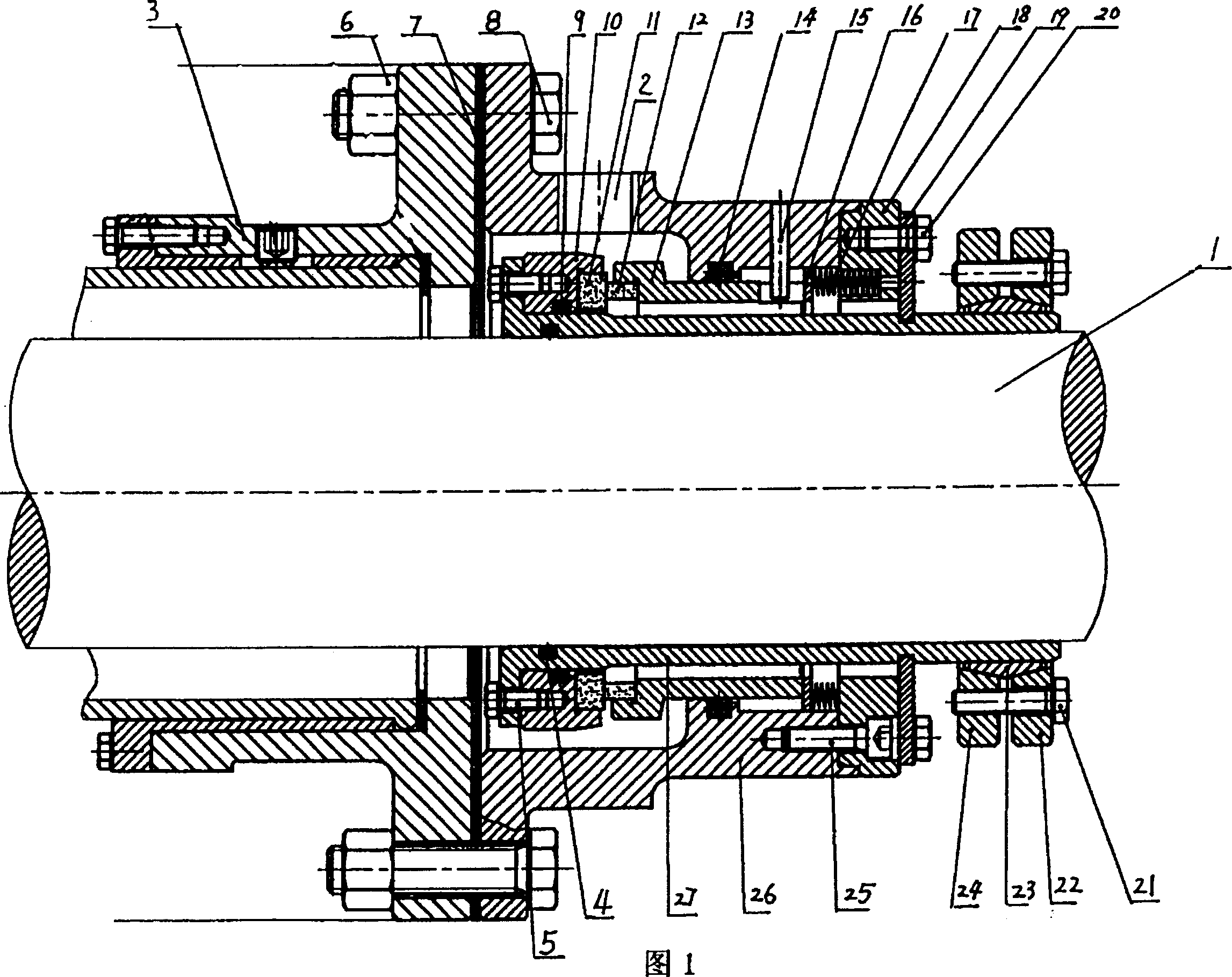

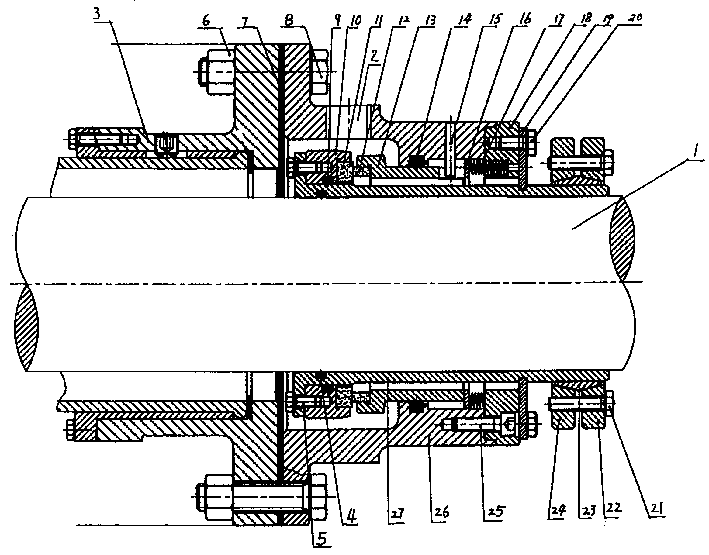

[0029] Embodiment: See Figure 1, its structure and principle have been described above, and the numbers of each part include: stern shaft 1, water inlet 2, stern shaft bearing sleeve 3, shaft sleeve "O" ring 4, transmission bolt 5, nut 6 , Stern shaft bearing sleeve gasket 7, bolt 8, moving ring "O" ring 9, moving ring seat 10, moving ring 11, static ring 12, static ring seat 13, static ring "O" ring 14, anti-rotation Pin 15, push ring 16, spring 17, spring seat 18, spacer 19, spacer bolt 20, locking ring bolt 21, locking ring 22, 23, 24, spring seat screw 25, gland 26, bushing 27 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com