Triple eccentric metal seal butterfly valve

A metal-sealed, triple-eccentric technology, applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of triple-eccentric butterfly valves that are difficult to meet high temperature requirements, increase the cost of valves, and flexible graphite is easy to be damaged. Self-centering performance, enhanced elasticity, and reduced pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

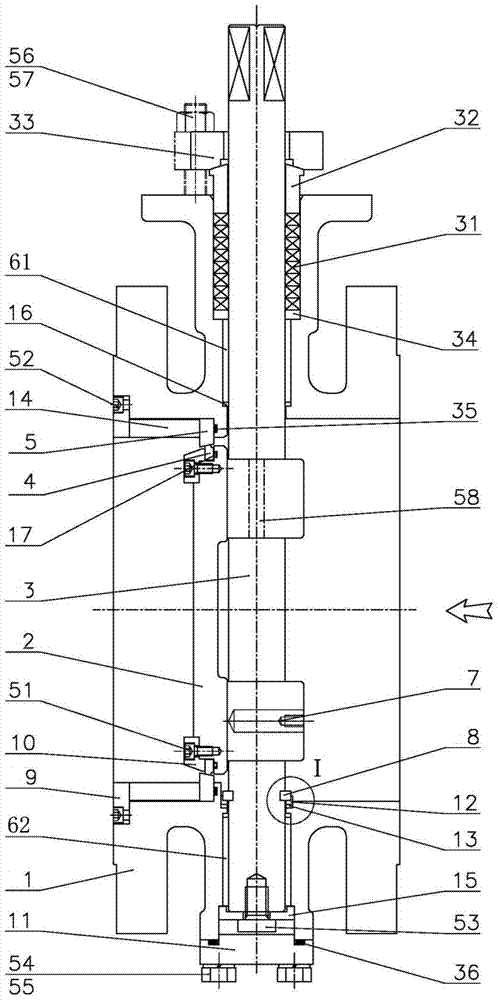

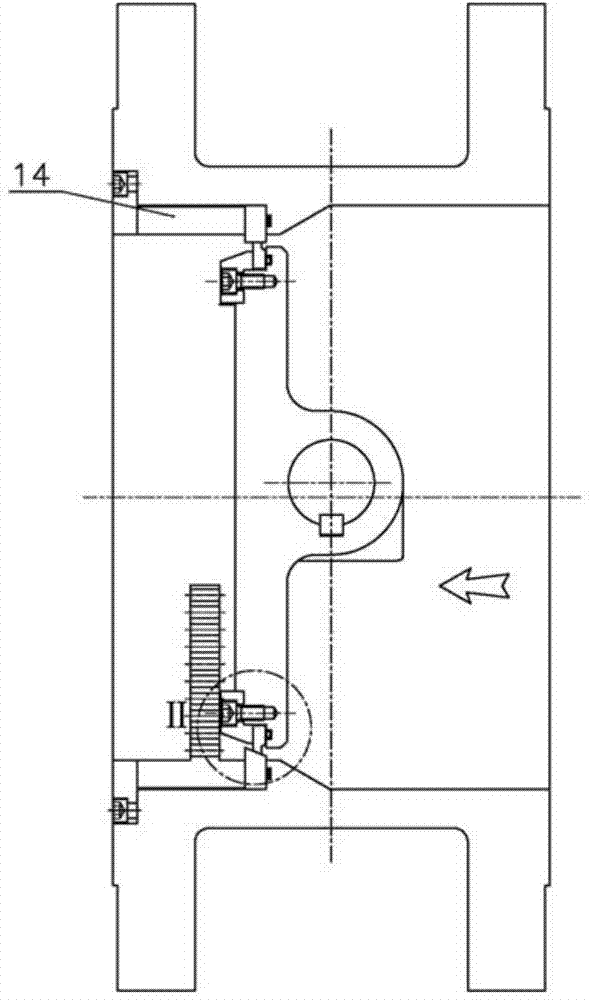

[0025] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

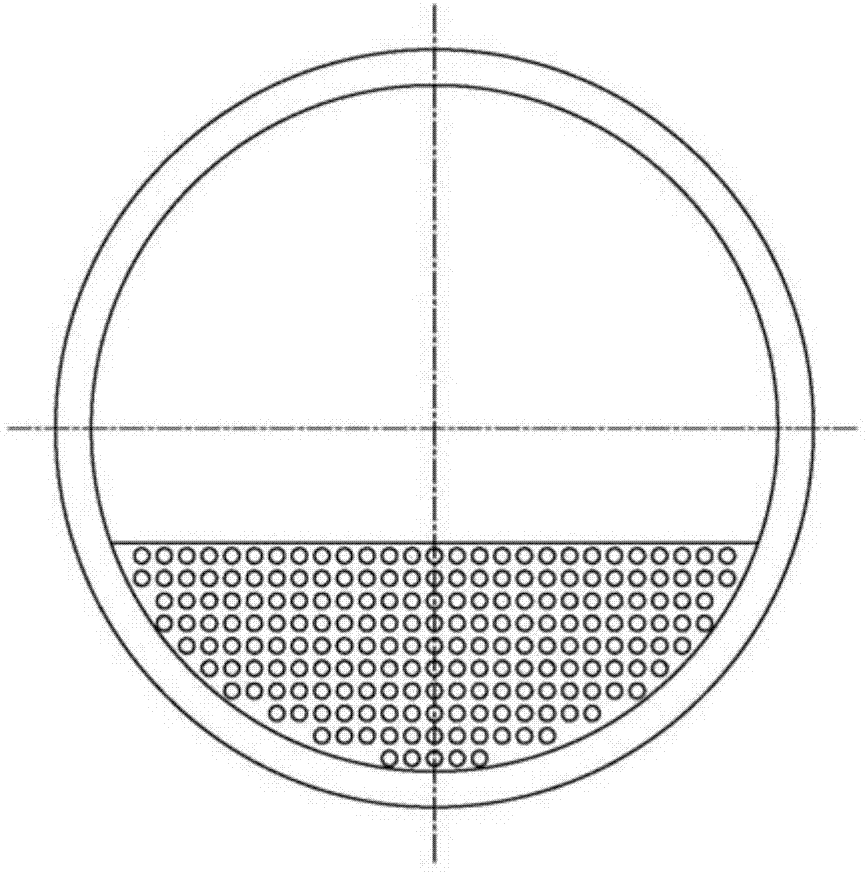

[0026] Such as Figure 1-Figure 5 As shown, including valve body 1; valve plate 2; valve stem 3 (packing 31; packing gland 32; packing gland 33; packing gasket 34; valve body sealing ring gasket 35; bottom cover gasket 36); valve plate seal Ring 4; valve body sealing ring 5 (hexagon socket head cap screws 51, 52; limit screw 53; hexagon head bolt 54; spring washer 55; stud stud 56; hexagon nut 57; keyway 58); the first metal bearing 61. The second metal bearing 62; pin 7; limit semi-circular ring 8; valve body pressure ring 9; valve plate pressure ring 10; bottom cover 11; thrust pad 12; gasket 13; unilateral porous pressure ring 14; Limiting plate 15; Bearing pad ring 16; Metal hollow O-ring 17.

[0027] In the present invention, the connection between the valve stem 3 and the valve plate 2 is installed in the valve body 1 by means of an upper key a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com