A connection structure of heat exchange tube and tube sheet for preventing crevice corrosion on shell side

A tube-sheet connection and heat-exchange tube technology, which is used in air-conditioning, heat-exchange equipment in the petrochemical industry, and coal chemical industry, can solve problems such as corrosion of tube-sheets, and achieve the effects of extending service life, simple structure and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

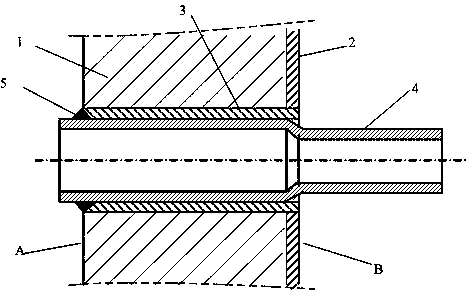

[0033] One of the specific implementations of the heat exchange tube and tube sheet connection structure for preventing shell side crevice corrosion of the present application includes a tube sheet and a heat exchange tube 4, the tube sheet is provided with tube holes, and the tube sheet It includes a tube sheet body 1, one side of the tube sheet body 1 is the tube side A, and the other side of the tube sheet body 1 is the shell side B, wherein the tube sheet also includes a preset A bidirectional composite layer composed of the first composite layer 2 on the shell side B of the tube sheet body 1 and the second composite layer 3 preset on the inner wall of the tube hole (along the radial direction of the tube hole), the heat exchange The tube 4 passes through the bidirectional composite layer and is fixed and sealed with the tube sheet.

[0034] Specifically, a second composite layer 3 is provided on a partial surface of the inner wall of the tube hole, and the heat exchange t...

Embodiment 2

[0041]A second specific implementation of the connection structure between heat exchange tubes and tube sheets to prevent shell-side crevice corrosion. The main technical solution of this embodiment is the same as that of embodiment 1. The features that are not explained in this embodiment are adopted in embodiment 1. The explanations in , will not be repeated here. refer to figure 2 As shown, the difference between this embodiment and embodiment 1 is that the second composite layer 3 is provided on the entire surface of the inner wall of the tube hole. It has the best anti-corrosion effect, but weakens the strength of the tube sheet body 1 to some extent.

specific Embodiment approach 3

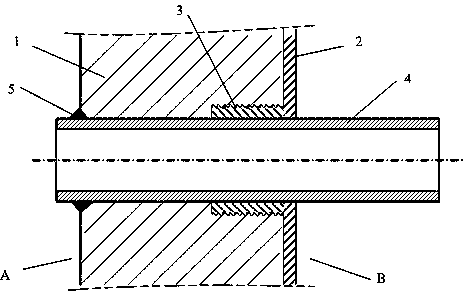

[0043] A specific implementation of the heat exchange tube and tube sheet connection structure for preventing shell-side crevice corrosion III. The main technical solution of this embodiment is the same as that of Embodiment 1. The features not explained in this embodiment are adopted in Embodiment 1 The explanations in , will not be repeated here. refer to image 3 As shown, the difference between this embodiment and Embodiment 1 is that the second composite layer 3 is provided with external threads on one side of the tube sheet body 1, and the tube sheet body 1 is provided with external threads that cooperate with the external threads. Connected internal thread, the heat exchange tube 4 passes through the bidirectional composite layer, and is fixed and sealed with the tube sheet.

[0044] Part of the second composite layer 3 on the inner wall of the pipe hole is connected to the pipe hole through threads. After the second composite layer 3 is compounded in the pipe hole, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com