Rotary conveying device for shoe-making beading machine

A technology of transmission device and edge pressing machine, which is applied in the direction of shoemaking machinery, footwear, application, etc., can solve the problems of low efficiency and achieve the effect of improving work efficiency, reasonable design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

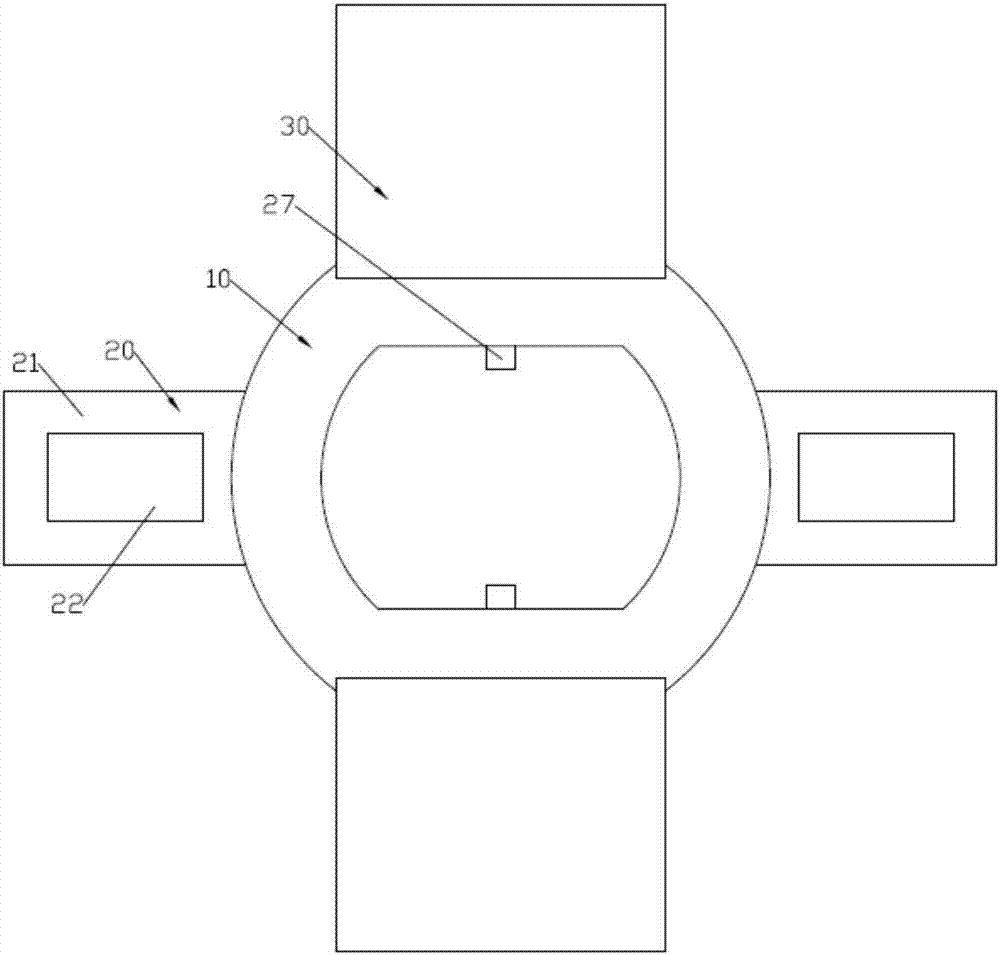

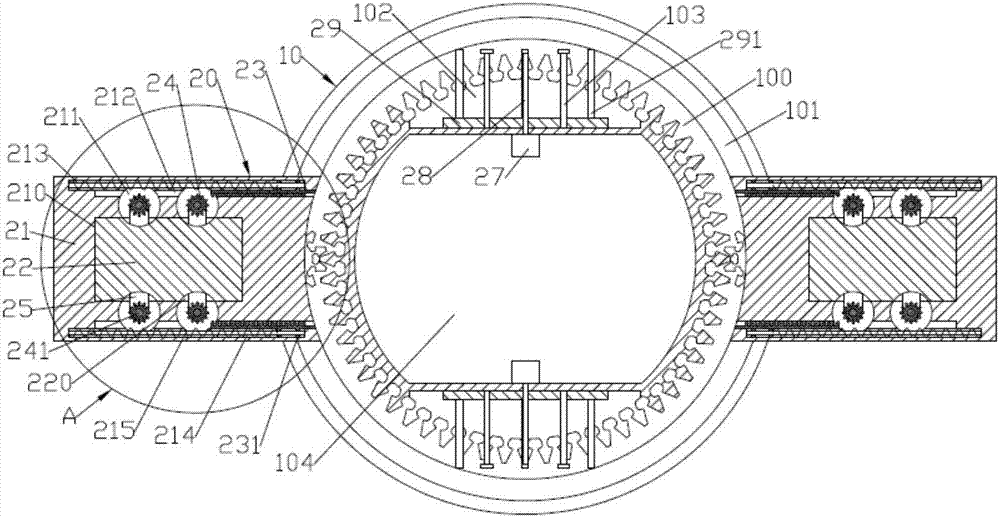

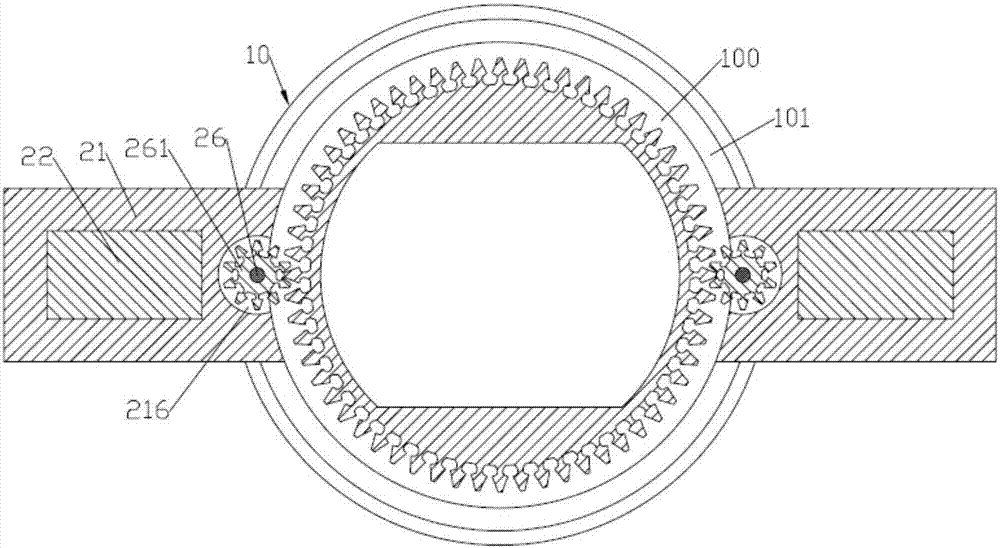

[0017] Such as Figure 1 to Figure 4 As shown, a rotary transmission device for a shoe-making edge press includes a frame 10, a pair of symmetrically arranged loading platforms 20, and a pair of front and back symmetrically arranged edge presses 30; the frame 10 includes a cylindrical Support frame and several support legs; several support legs are evenly fixed on the lower end surface of the support frame; the middle part of the support frame is provided with a long hole-like operation slot 104 that penetrates up and down; the outer cylindrical surface of the support frame is formed with a circular rotating Groove 100; a pair of loading platforms 20 are slided and arranged in the rotating slot 100; the loading platform 20 includes a square platform body 21, a square lifting center platform 22 and a limiting device; the lifting center platform 22 is installed on the platform through the limiting device On the main body 21 ; the upper parts of the front and rear sides of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com