Self-powered maintenance device and method for photoelectric equipment

A technology for maintenance and equipment, which is applied in general control systems, instruments, computer control, etc., can solve problems such as many manual steps involved, battery overcharge damage, high laser pulse trigger frequency damage equipment, etc., to improve the efficiency of power-on maintenance , reasonable design and simplified manual operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

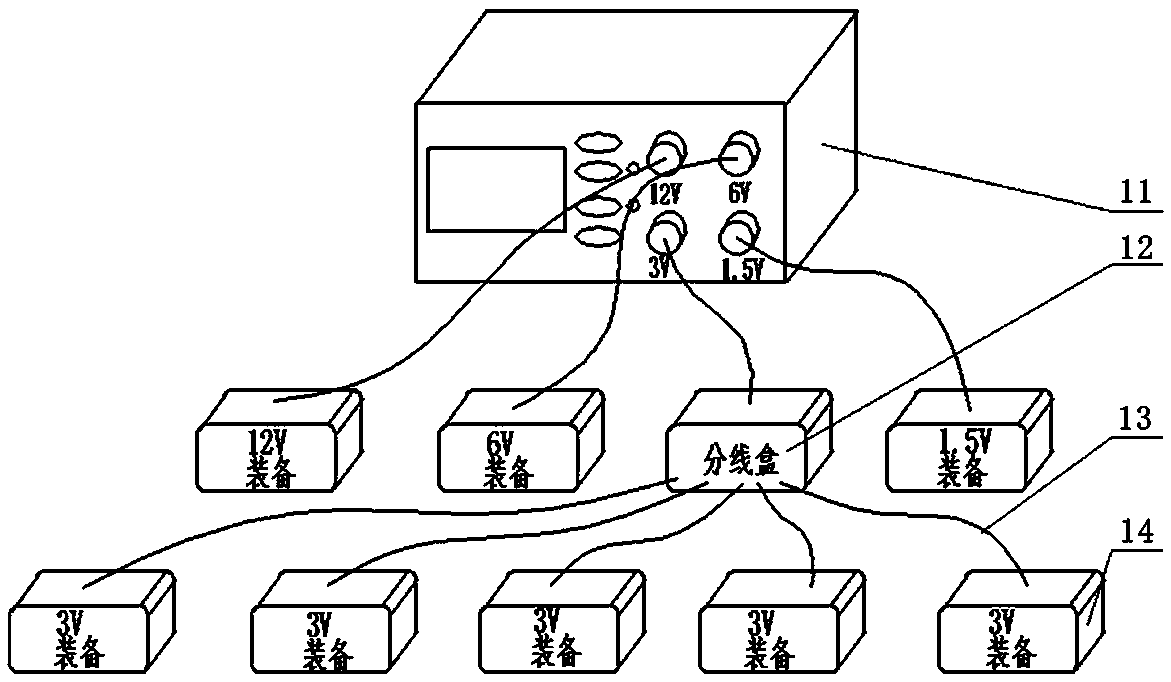

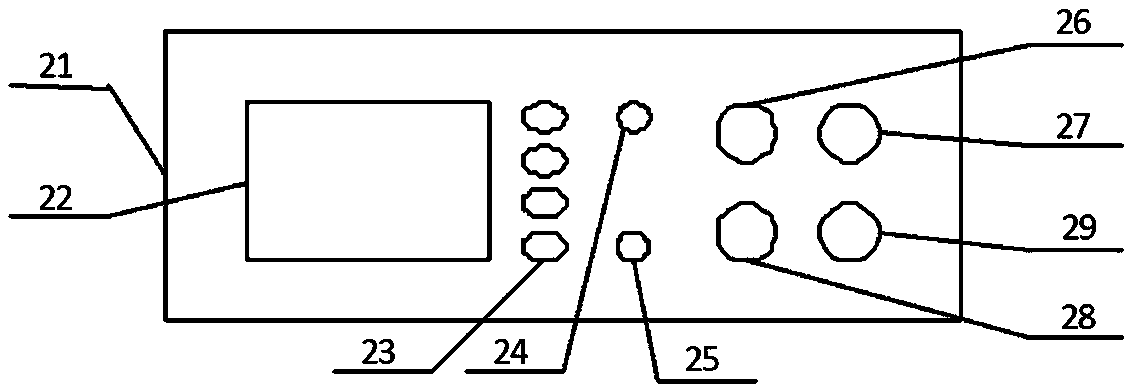

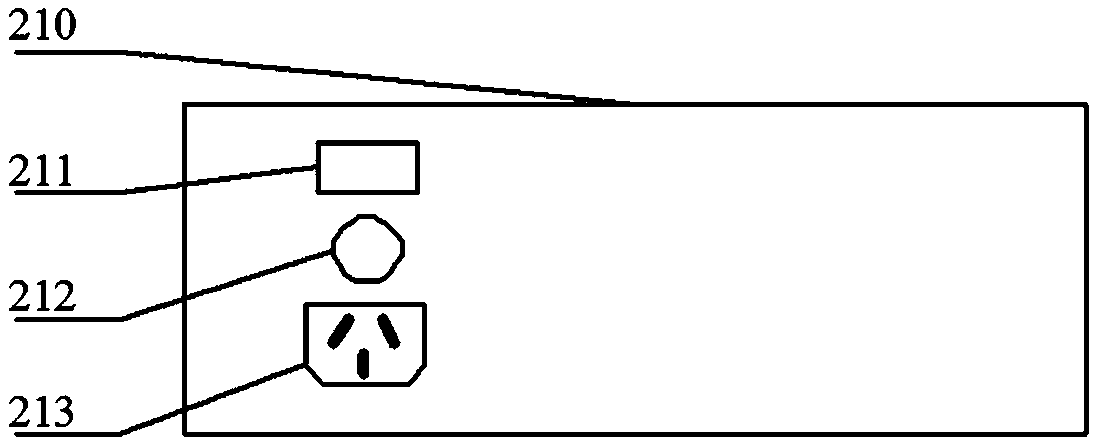

[0039] Such as figure 1 As shown, the self-powered maintenance device for optoelectronic equipment provided by the present invention includes a host 11 (or called the main unit of the self-powered maintenance device), a junction box 12 and supporting cables 13 . The main frame 11 is a cuboid box body structure, and it comprises a case shell, and a front control panel 21 (such as figure 2 shown), a rear control panel 210 is provided on the rear panel of the chassis shell (such as image 3 shown), with a circuit board inside the chassis shell. The host 11 can output 1.5V, 3V, 6V, 12V multi-level DC voltage at the same time, cooperate with the junction box 12 to expand the interface, and can support multiple types of equipment for simultaneous maintenance, which greatly improves the efficiency of power-on maintenance. The voltage output by the host 11 can be directly connected to the optoelectronic equipment, or can be connected to the optoelectronic equipment 14 after going t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com