Double-mode valve device and fluid supply system thereof

A valve device, valve device technology, applied in valve device, multi-port valve, engine components and other directions, can solve the problem of rough control of water temperature and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] A valve device, comprising a valve device for controlling a fluid passing state when the fluid passes through, and an operating mechanism for realizing the aforementioned control by operating in its operating region, the valve device has a first fluid inlet port, a second fluid inlet port and a fluid At the outlet end, the operation area of the operating mechanism is divided into a mixing degree adjustment area for adjusting the mixing degree of the first fluid and the second fluid, and a flow adjustment area for adjusting the flow rate of the fluid outlet in the mixing degree adjustment area. The mixing degree adjustment area includes necessary The fluid outlet port exits only the first fluid region of the first fluid, and the fluid outlet port exits only the second fluid region of the second fluid, and there may be a fluid outlet port exiting the mixing region of the mixed fluid of the first fluid and the second fluid The flow rate of the operating mechanism at the m...

Embodiment 2

[0101] This embodiment is similar to Embodiment 1, the difference is that in this embodiment, the water-saving valve core is in the critical state of Mode A when the control handle is placed in the lower stop position of Mode A, and when the control handle is placed in the lower stop position of Mode B The water spool is in the closed state, from the lower stop of mode A to the upper stop of mode A is the large flow adjustment area of the water-saving spool A mode, and from the lower stop of mode A to the lower stop of mode B is the water-saving spool A mode Small flow regulation area.

[0102] In this embodiment, the flow rate in the critical state of mode A of the water-saving valve core is set to 5 liters / minute. In this way, the adjustment area of the water-saving valve core A mode is divided into a large flow adjustment area and a small flow adjustment area, that is, from the lower stop position of the A mode to the upper stop position of the A mode, the water-saving ...

Embodiment 3

[0105] Such as Figure 1 to Figure 6 As shown, this embodiment is basically the same as Embodiment 1. More specifically, this embodiment is a ceramic disc single-handle dual-mode water-saving valve core. The control handle has an upper stop, an adjustment area and a lower stop. The core state has an on state and an off state. In this embodiment, the water-saving valve core is provided with a mode and a mode B. The maximum flow rate in the adjustment area of the A mode is 20 liters / minute, and the maximum flow rate in the adjustment area of the B mode is 5 liters / min.

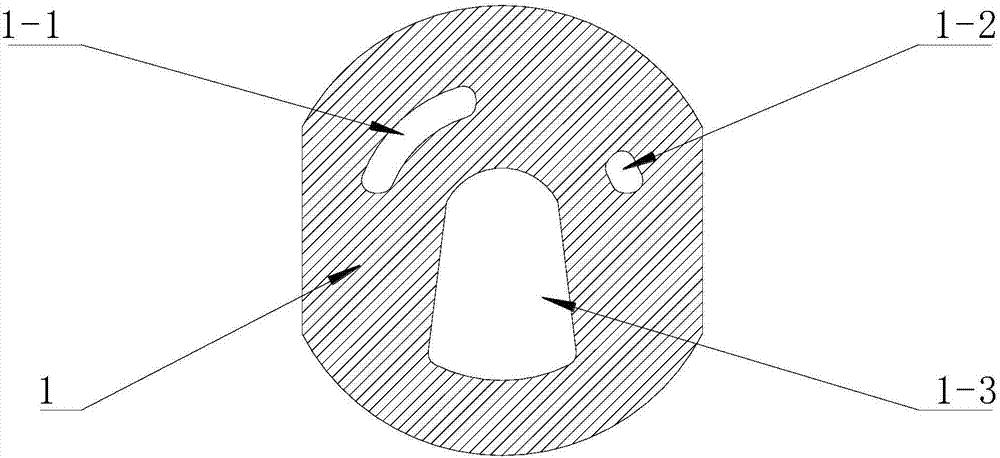

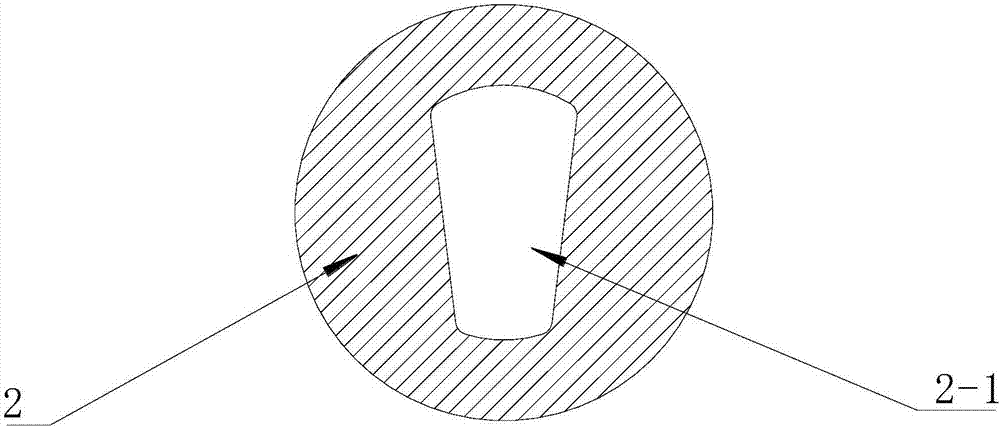

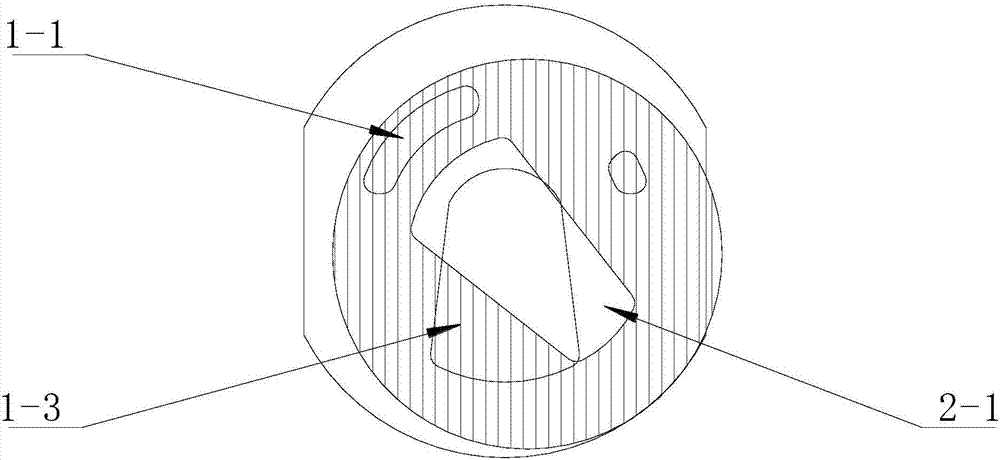

[0106] figure 1 Be fixed plate 1 sectional schematic diagram, (among the figure) top left side is first water inlet 1-1, top right side is second water inlet 1-2, and bottom is water outlet 1-3. figure 2 It is a schematic cross-sectional view of the moving piece 2, and the middle part (in the figure) is the channel 2-1. The single-handle double-mode water-saving valve core of the present embodiment is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com