Method for controlling screwing spindle

A control method, piston technology, applied in the direction of bottle filling, packaging, screw caps, etc., can solve the problem of damage to the cap or the neck of the package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

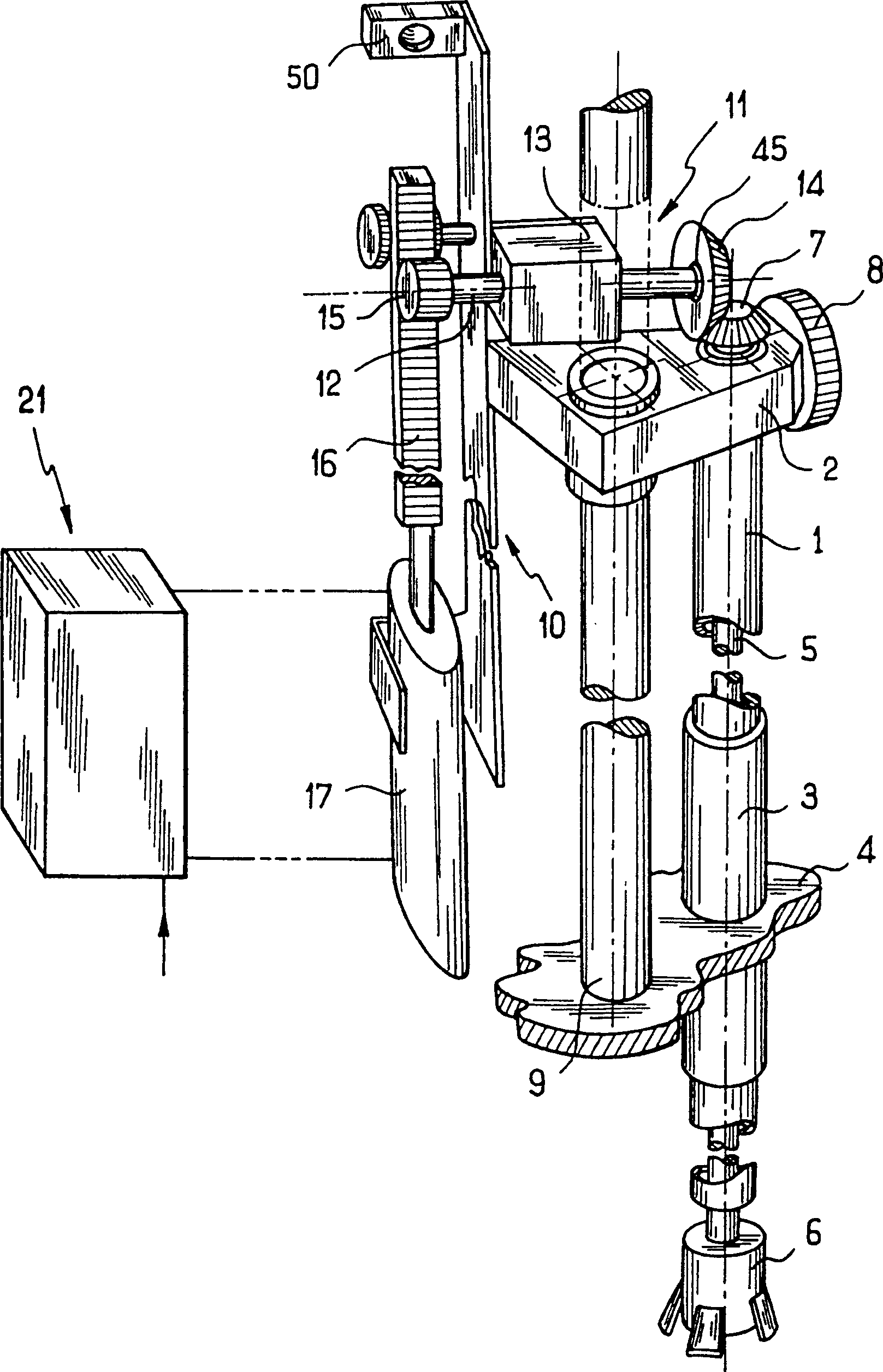

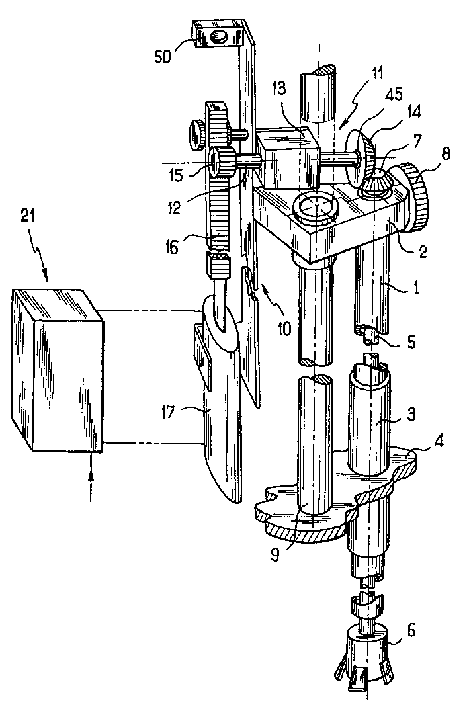

[0019] Referring to the drawings, the screwdriver controlled by the method of the present invention is conventional in structure and operation, some of its components not shown in the figures. In the embodiment shown, the shaft comprises a vertical guide tube 1 housed in a shaft support 2 and slidable vertically in a bushing 3 fixed to a rotating platform 4 . The guide tube 1 rotatably receives a mandrel 5, the bottom end of which protrudes outside the guide tube 1, and has a jaw chuck device 6 on which the cover is placed. The top of mandrel 5 has a bevel gear 7, and this gear and reference figure 1 Cooperate with the drive components shown in the overall above.

[0020] The shaft support 2 is mounted so as to slide on a column 9 fixed to the rotating platform 4, the support has a wheel 8 designed to cooperate with a cam of a stationary structure for positioning the support 2 and in the vertical direction. Fits with its associated parts in the vertical direction.

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com