Corn combine capable of harvesting both spikes and stalks

A combine harvester and corn technology, applied to the chassis of harvesters, balers, and agricultural machinery, etc., can solve the problems of inconvenient use, non-adjustable angle and height of the front silage, and achieve the effect of convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

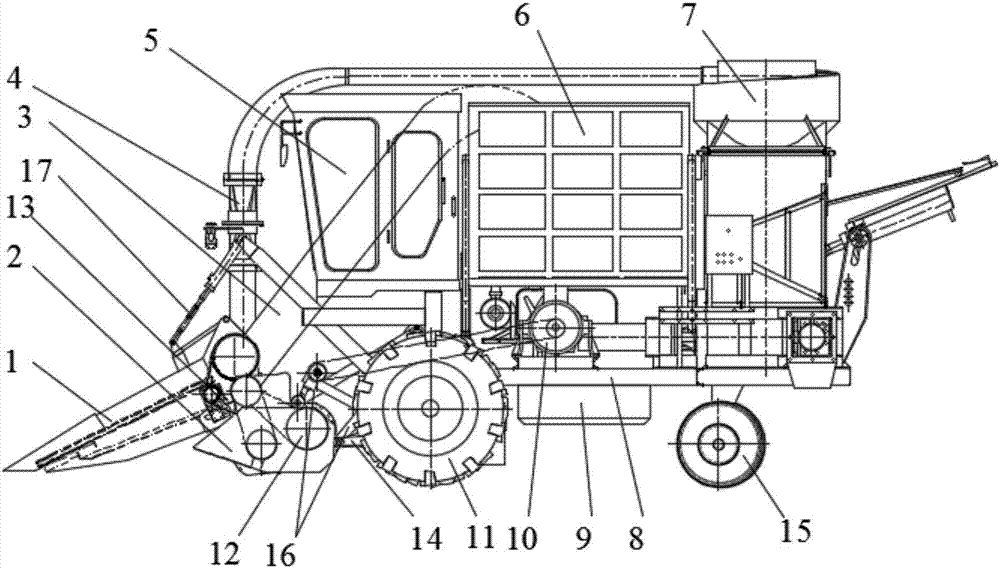

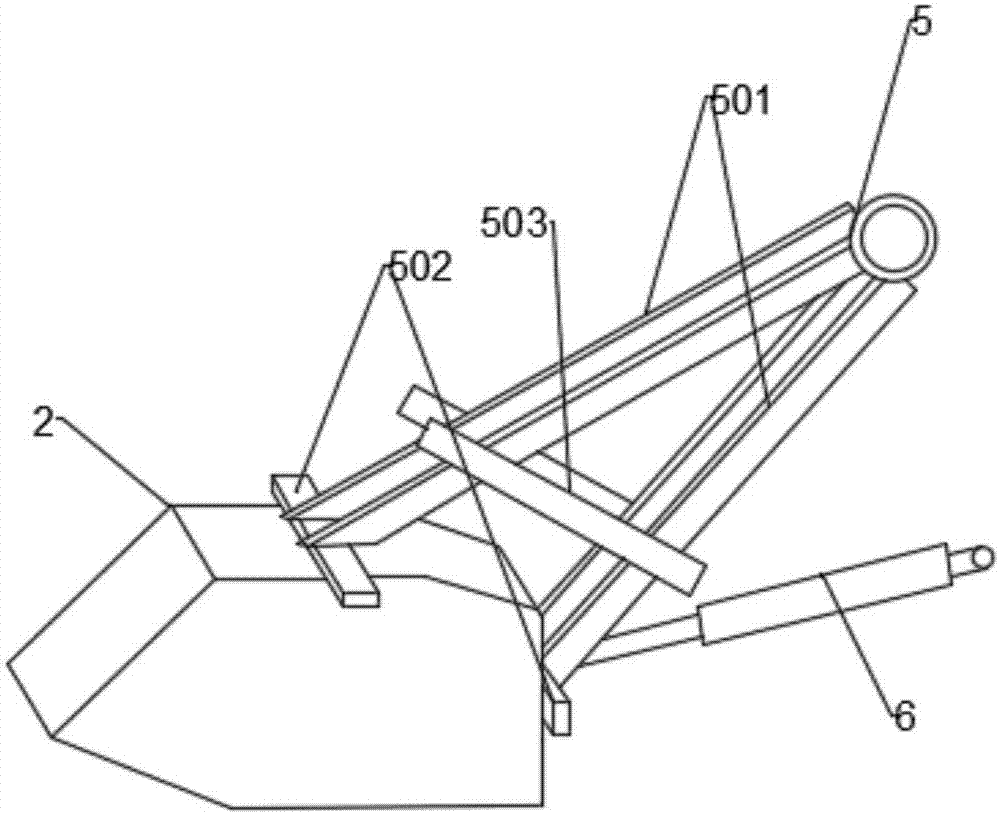

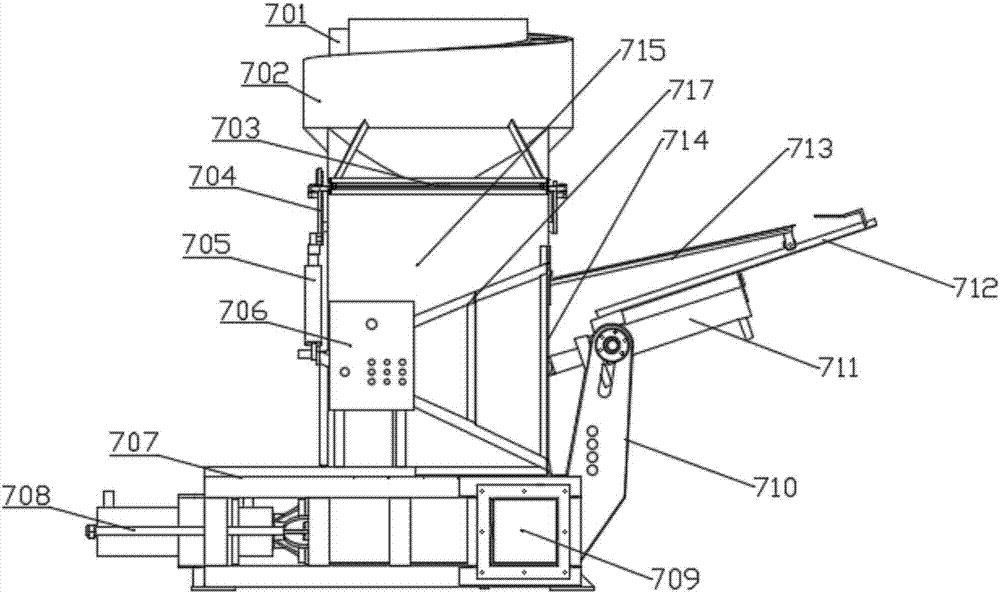

[0023] Such as figure 1 and 2 Shown, a kind of corn combine harvester of ear and stalk harvesting type comprises frame, and described frame lower end is provided with front drive wheel 21 and rear guide wheel 15, and described frame is provided with cab 5 near the front end, close to The middle part is provided with an engine 10 and an oil tank 9, and the front end of the frame is provided with a header 1, and a front silage 2 is arranged between the header 1 and the front drive wheel 11, and the front silage 2 and The headers 1 are all driven by the transmission system. The front silage 2 is fixedly connected to the lower end of the suspension device 16. The upper end of the suspension device 16 is hinged and fixed to the chassis 8 of the frame through a shaft. The suspension device 16 The rotation angle of its relative shaft is controlled by the first electro-hydraulic telescopic rod 14 so as to adjust the height and angle of the front silage 2 from the ground. The front si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com