A kind of bone conduction music pillow and its processing method

A processing method and bone conduction technology, applied in pillows, applications, home appliances, etc., can solve the problems of moldy traditional Chinese medicine, hygienic health, uneven layers of health care pillows, and failure to promote sleep, so as to relieve shoulder and neck pressure and use Long life and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

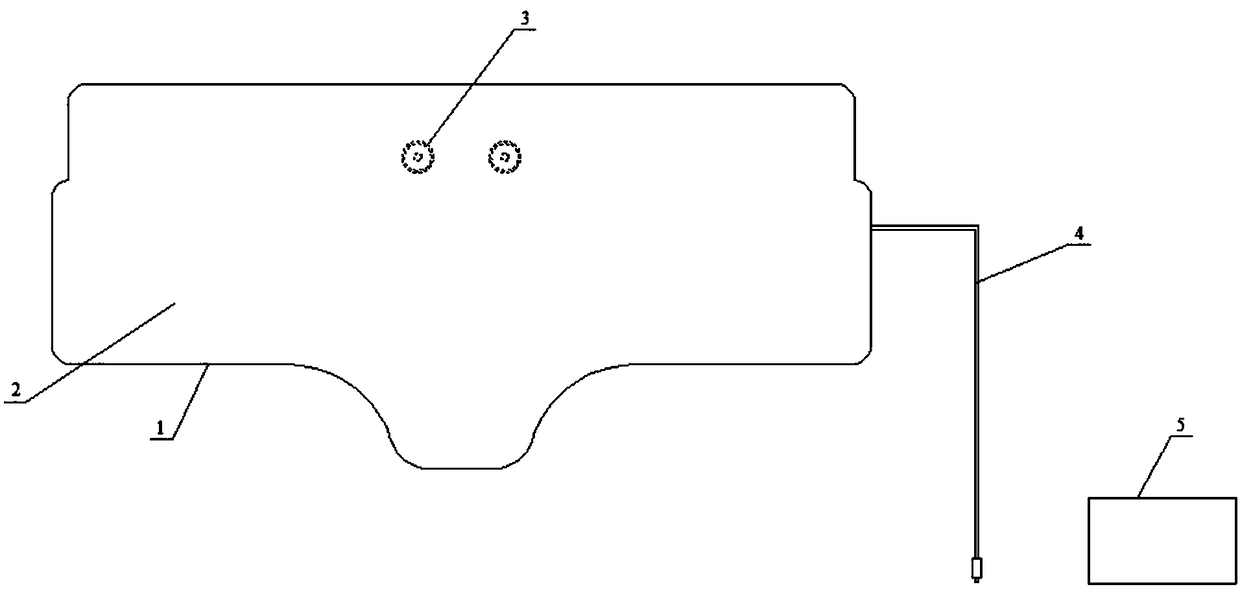

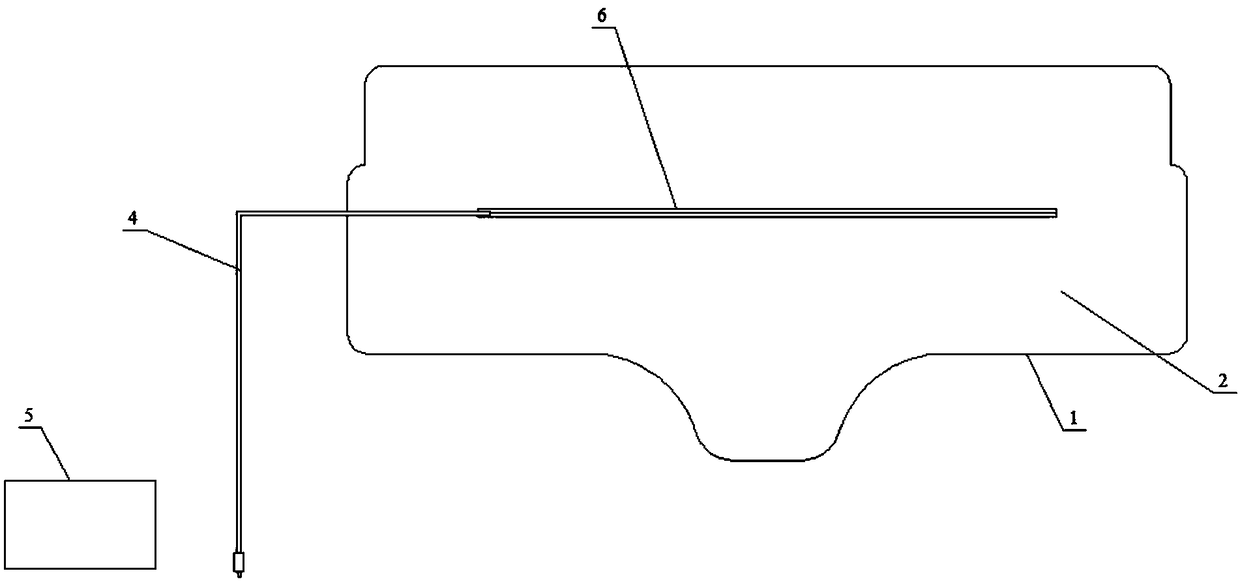

[0028] Such as figure 1 and figure 2 Shown, a kind of bone conduction music pillow comprises pillow body, and described pillow body is butterfly-shaped structure, comprises the pillow case 1 that is made of velvet fabric, the pillow core 2 that is made by slow-rebound sponge and is fixed on the top of pillow core The loudspeaker 3 is connected to the audio player 5 outside the pillow body through the audio connection line 4. The audio player is selected from a smart phone, a tablet computer or other players with audio output and volume adjustment functions. The loudspeaker is symmetrically provided with 2 , with a zipper on the back of the pillowcase6.

[0029] (1) select the high-grade velvet that is produced as the pillowcase fabric with acetate fiber and acrylic fiber as raw material, through cutting, sewing, make the pillowcase that outward appearance is butterfly structure;

[0030] (2) Use slow rebound sponge as the filling material of the pillow core, process the slo...

Embodiment 2

[0038] Preparation of slow rebound sponge: Add 5kg of down fiber and 3kg of soybean fiber to 10kg of gelling aid, raise the temperature to 120-125°C for 15min, heat-preserve and grind for 15min, then microwave for 5min at a microwave frequency of 2450MHz and an output power of 700W to obtain gel Glue fiber: Stir 70kg polyether polyol, 15kg trihydroxy polyether, 5kg blowing agent and 0.5kg catalyst at a speed of 4000-4500r / min for 30s, then add gel fiber, 2kg glycerol polyether and 1kg foam stabilizer , continue to stir for 10 seconds, pour the foamed liquid into the mold, and cut after 24 hours to obtain a slow rebound sponge.

[0039] Wherein, the polyether polyol is selected from polyoxypropylene triols with a hydroxyl value of 45-65 and a functionality of 2.5-4.5.

[0040]The catalyst consists of 50% by mass of amine catalyst A33, 30% of organotin catalyst T9 and 20% of catalyst A1.

[0041] Preparation of gelling aid: Add 90-95°C hot water to 5kg of polyvinyl alcohol resi...

Embodiment 3

[0060] The slow resilience sponges prepared in Example 1, Example 2, Comparative Example 1, Comparative Example 2 and Comparative Example 3 were tested for performance, and the test results are shown in Table 1.

[0061] The performance of slow rebound sponge made in table 1

[0062]

[0063] Note: The determination condition of support coefficient is 80% pressure limit vs. 25% pressure limit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com