Conveyor system

A technology of conveying system and conveying device, which is applied in the field of conveying system, and can solve the problems such as the deviation of the cloth from the transfer position and the difficulty of detaching from the electrified device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

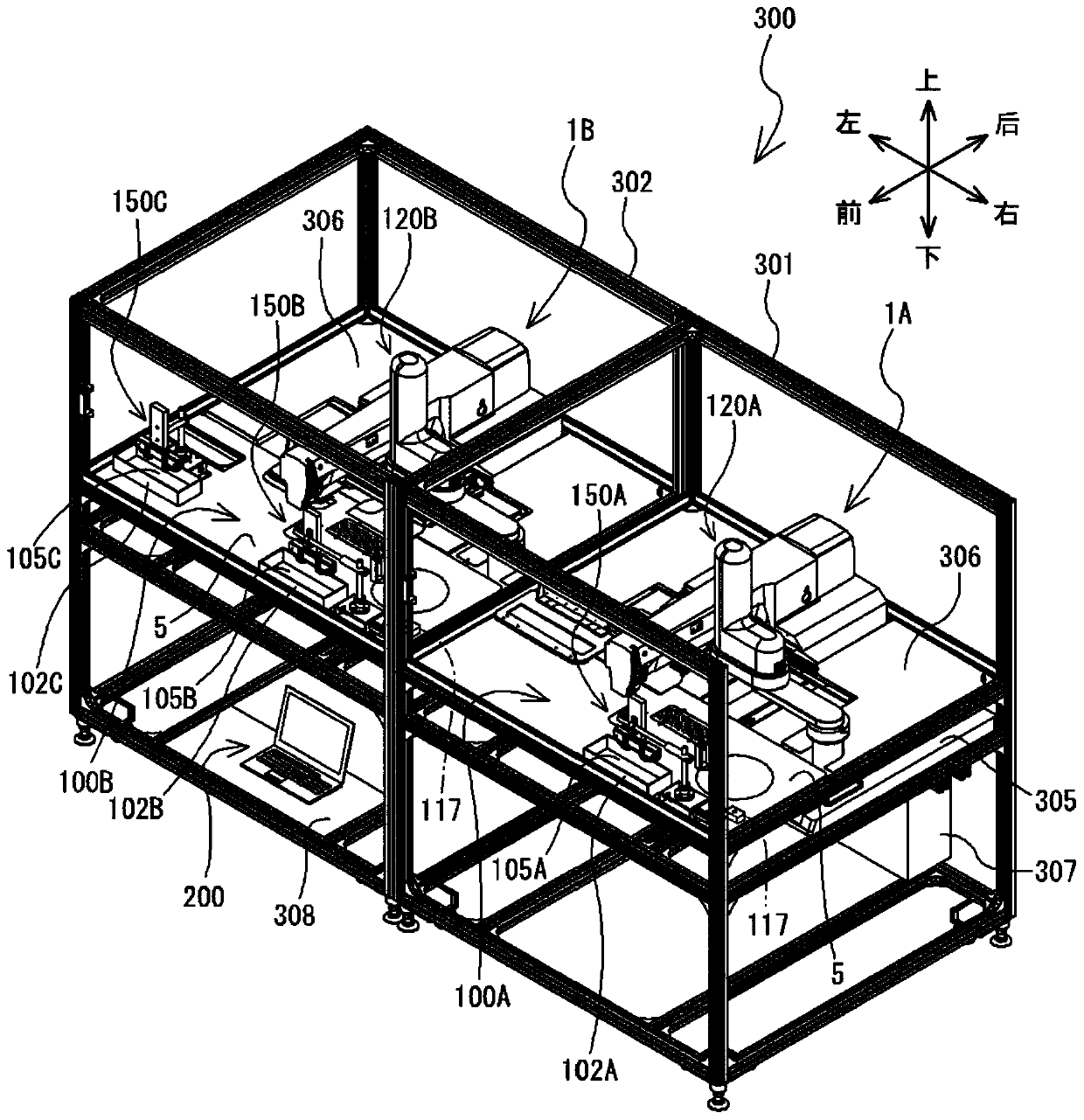

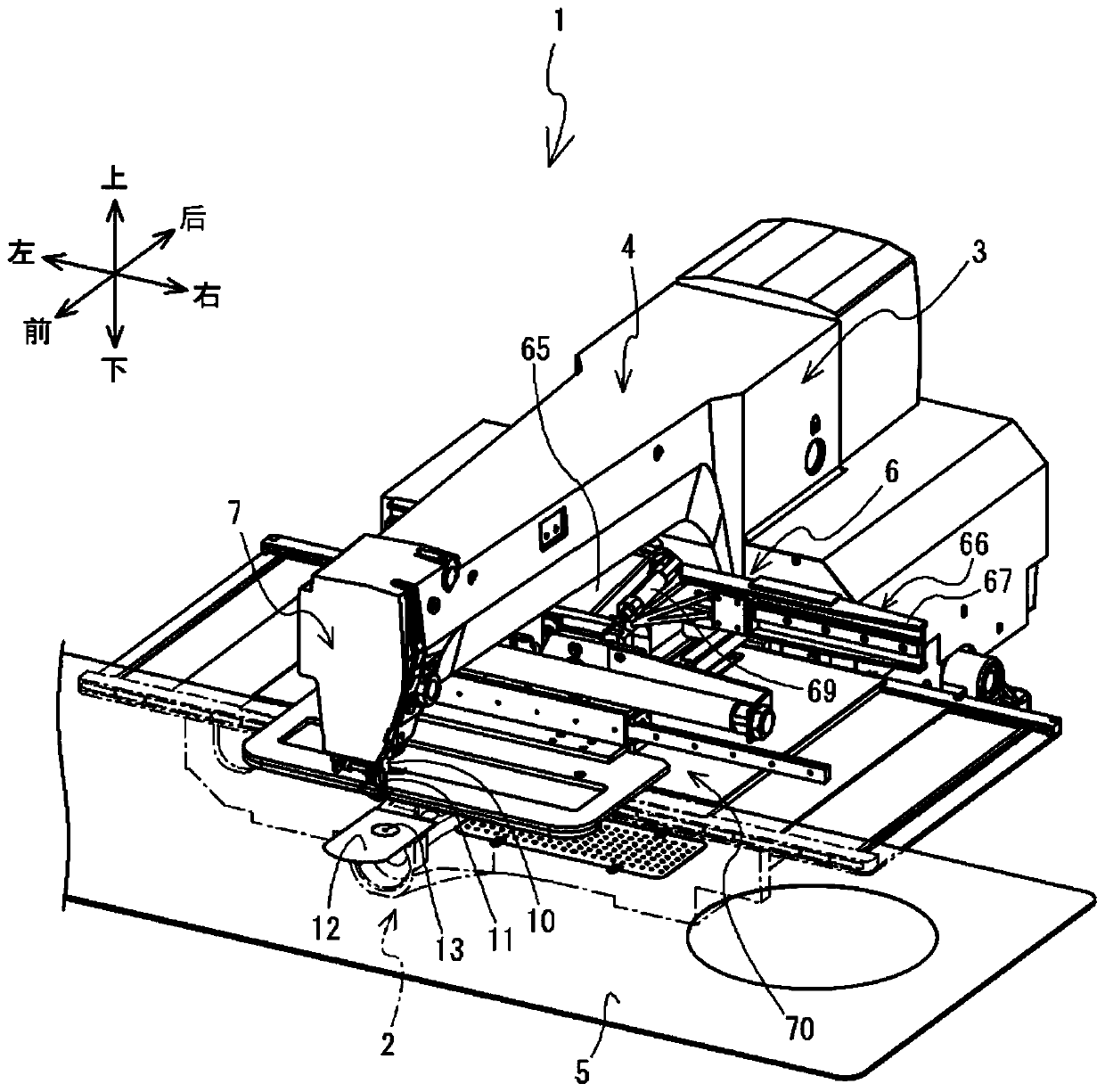

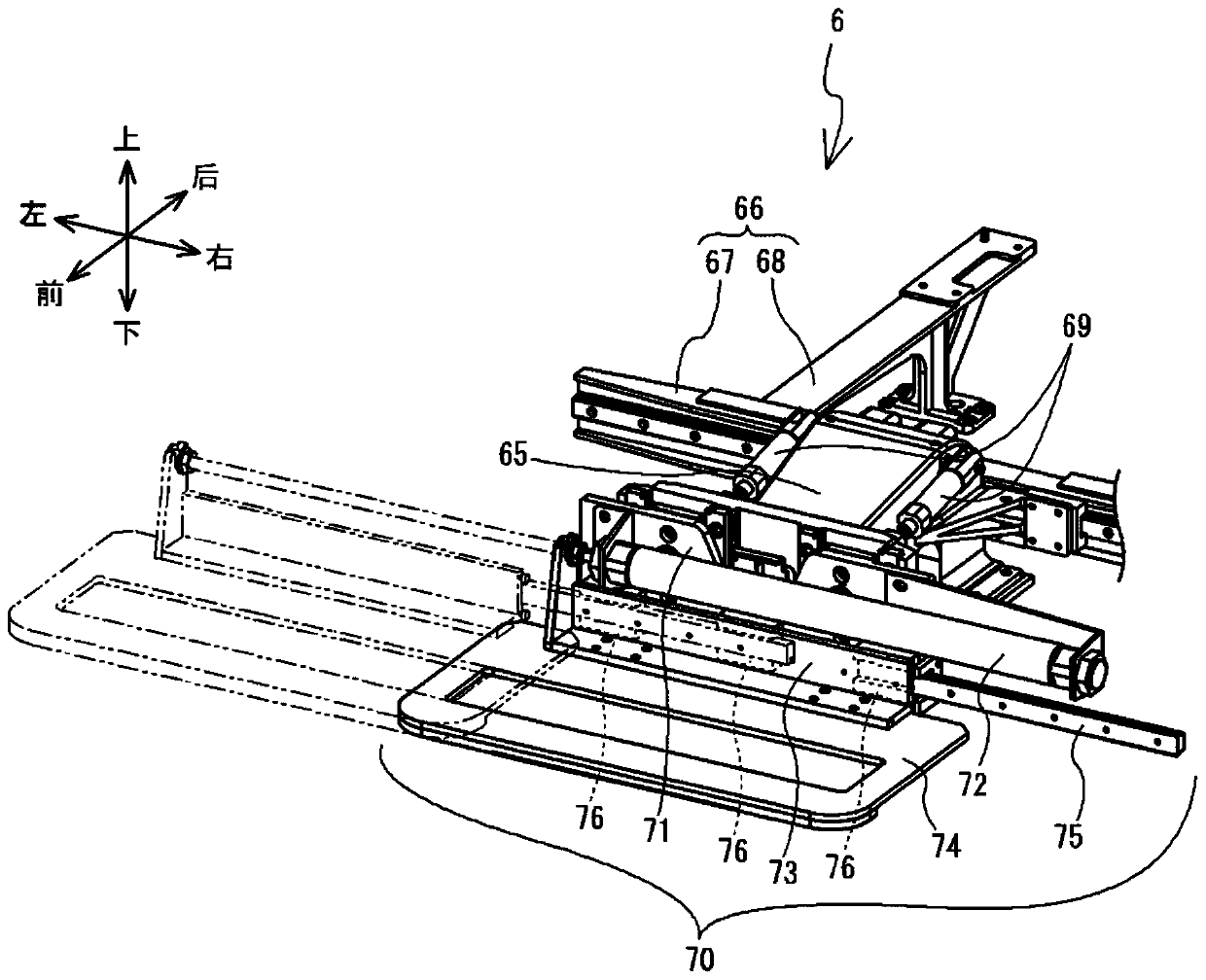

[0034] One embodiment of the present invention will be described with reference to the drawings. A schematic structure of the delivery system 300 will be described. The following description uses left and right, front and rear, and up and down indicated by arrows in the drawings.

[0035] Such as figure 1 As shown, the conveyance system 300 has two sewing machines, a sewing machine 1A and a sewing machine 1B, two conveyance devices, a conveyance device 100A and a conveyance device 100B, and one computer 200 . The sewing machine 1A and the sewing machine 1B have substantially the same configuration. In the following description, the sewing machine 1A and the sewing machine 1B are collectively referred to as the sewing machine 1 . The transport device 100A and the transport device 100B have substantially the same configuration. In the following description, the delivery device 100A and the delivery device 100B are collectively referred to as the delivery device 100 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com