Supporting device for curing oven

A technology of supporting device and curing furnace, which is applied in the directions of furnace, charge, furnace components, etc., can solve the problems of inability to change the position of curing furnace and complex structure, and achieve the effect of simple structure and flexible change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

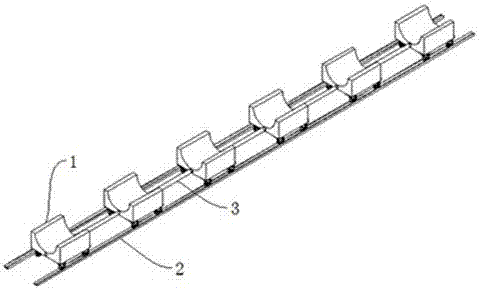

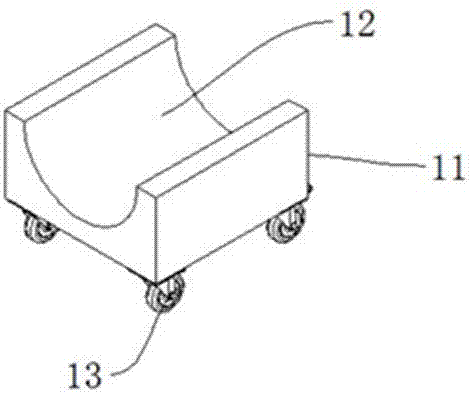

[0017] refer to figure 1 and figure 2 , a curing furnace supporting device, comprising six curing furnace supporting cars 1 on the same straight line and two guide rails 2 positioned below the curing furnace supporting cars; adjacent curing furnace supporting cars are fixedly connected with a connecting rod 3; Described curing furnace supporting vehicle comprises curing furnace supporting vehicle body 11 and four wheels 12 positioned at the bottom of described curing furnace supporting vehicle body; Described curing furnace supporting vehicle body upper surface is provided with groove 13; Described groove upper surface It has a shield layer. Described wheel has locking device. The fender layer is made of glass fiber impregnated epoxy resin. There is a wool felt layer on the guard plate layer.

[0018] The above-mentioned embodiments are only to illustr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com