Belt pressure wheel of a textile two-for-one twister

A technology of double twister and dragon belt, which is applied in the directions of spinning machine, textile and papermaking, continuous winding spinning machine, etc., to achieve the effects of high plasticity, easy acquisition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

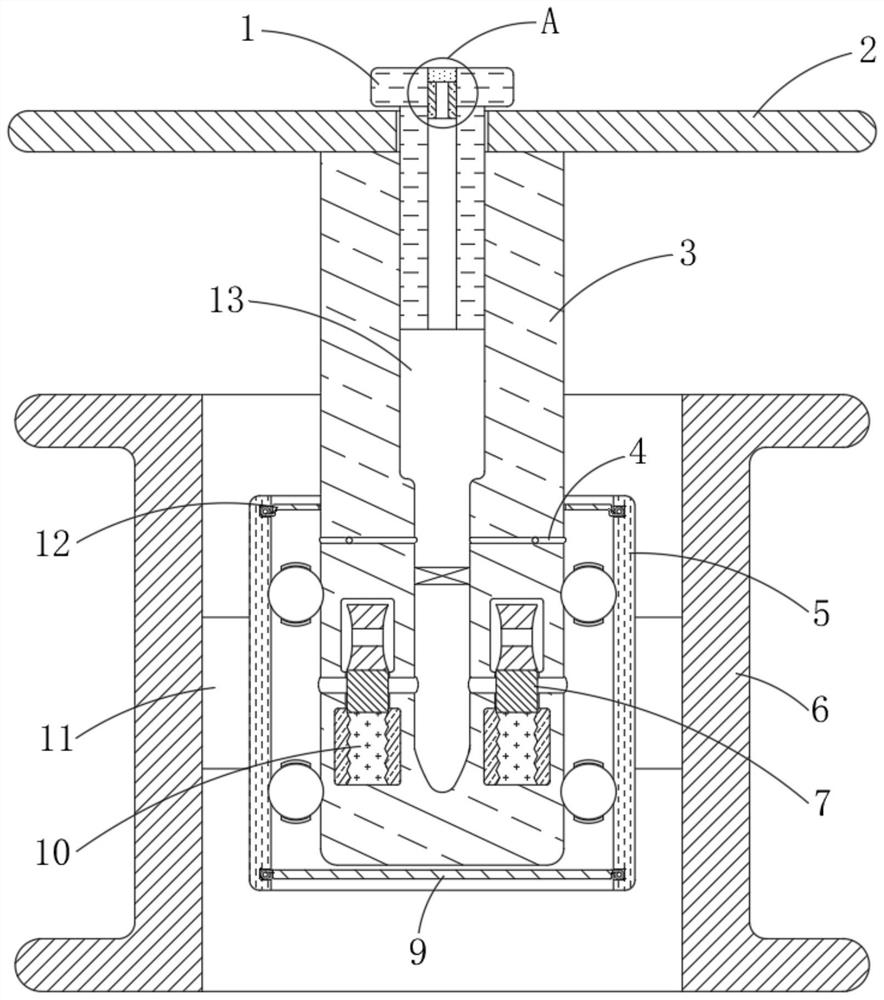

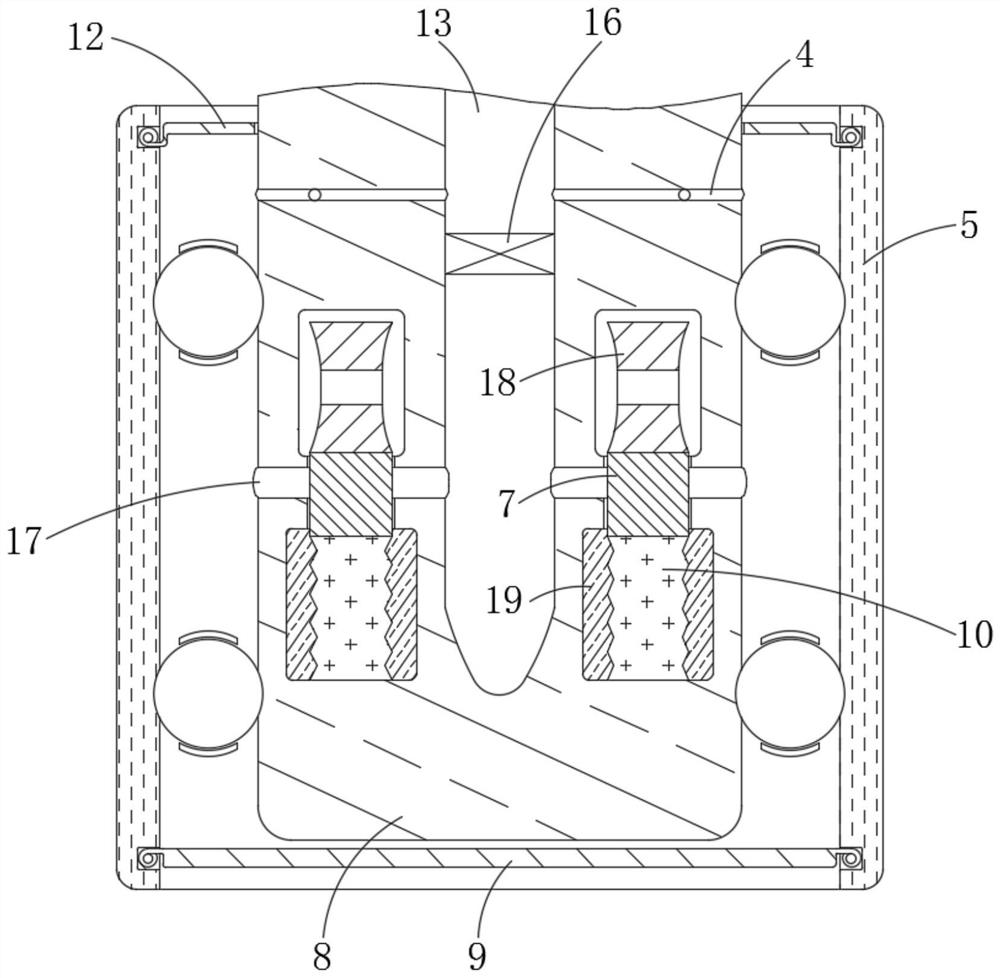

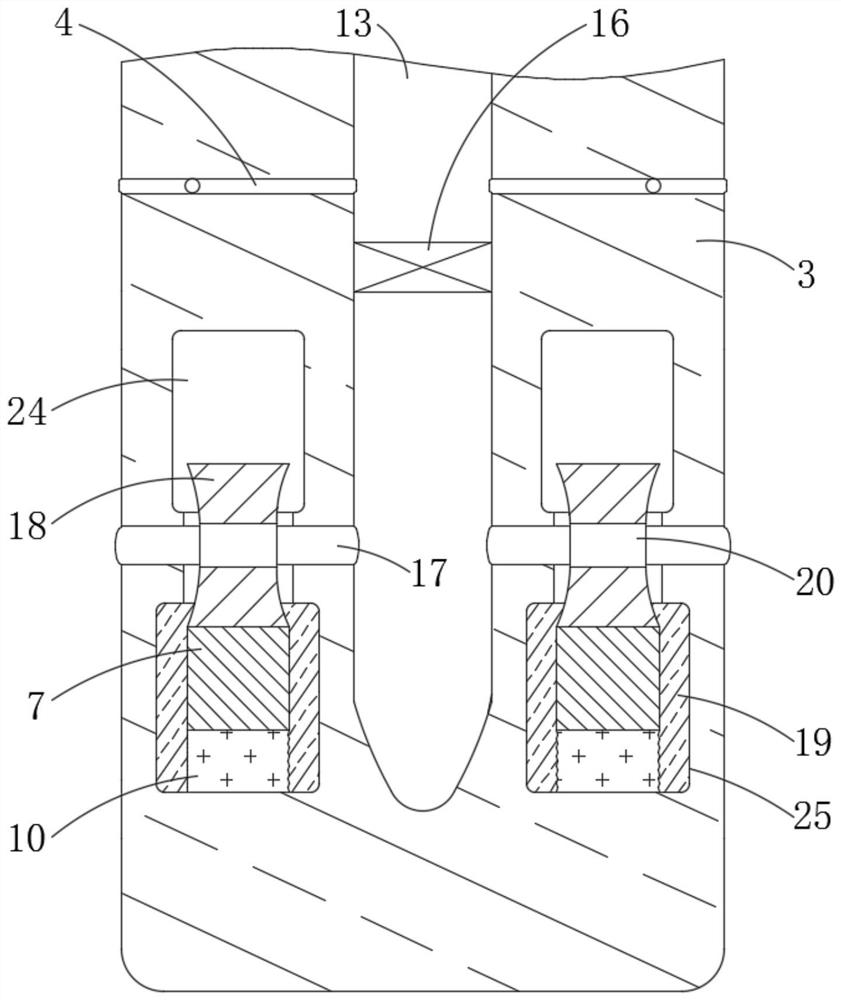

[0033] refer to Figure 1-6 , a kind of textile two-for-one twister belt pressure wheel, including body plate 2, fixed shaft 3, outer ring 5 and outer wheel 6, and a lubricating cavity is provided between the fixed shaft 3 and the outer ring 5, and the fixed shaft 3 passes through the bolt 1 is fixed on the side wall of the fuselage plate 2, and the outer ring 5 is fixed on the outer wall of the fixed shaft 3. The fixed shaft 3 and the bolt 1 are respectively provided with an oil injection cavity 13 and an oil injection cavity 23, and the oil injection cavity 23 is located in the oil injection cavity. within 13;

[0034] An oil filling nozzle 15 is stuck inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com