Wiring method for high-speed wire rods

A high-speed wire and wiring method technology, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve the problems of poor high-speed wire signals, affecting work efficiency, and costing wiring engineers' energy, reducing manual search time, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

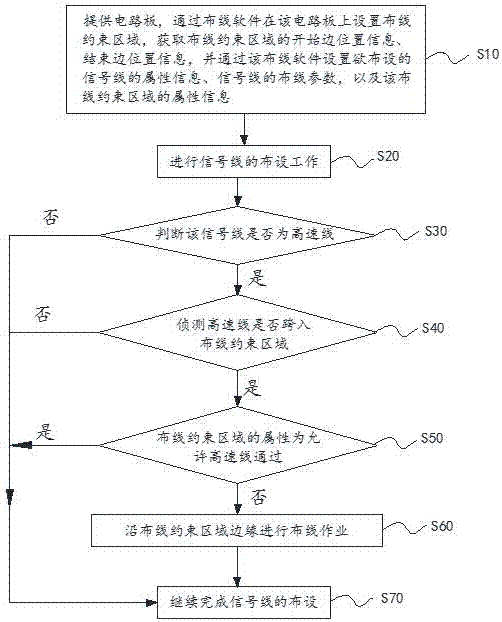

[0023] like figure 1 As shown, a high-speed wire wiring method provided by this embodiment includes the following steps: first, step S10 is performed, a circuit board is provided, a wiring constraint area is set on the circuit board through the wiring software, and the wiring restriction area is set through the wiring software. The attribute information of the signal line to be routed, the routing parameters, and the attribute information of the routing restricted area. In this embodiment, the routing restricted area is a GAP (Ground Gap).

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com