Single-trough and dual-roll secondary coating structure

A double-coating and single-slot technology, which is applied to the device for coating liquid on the surface, coating, and pre-treated surfaces, etc., can solve the problems of inconvenient operation, low efficiency, uneven gluing, etc., and improve production efficiency , Efficiency improvement, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

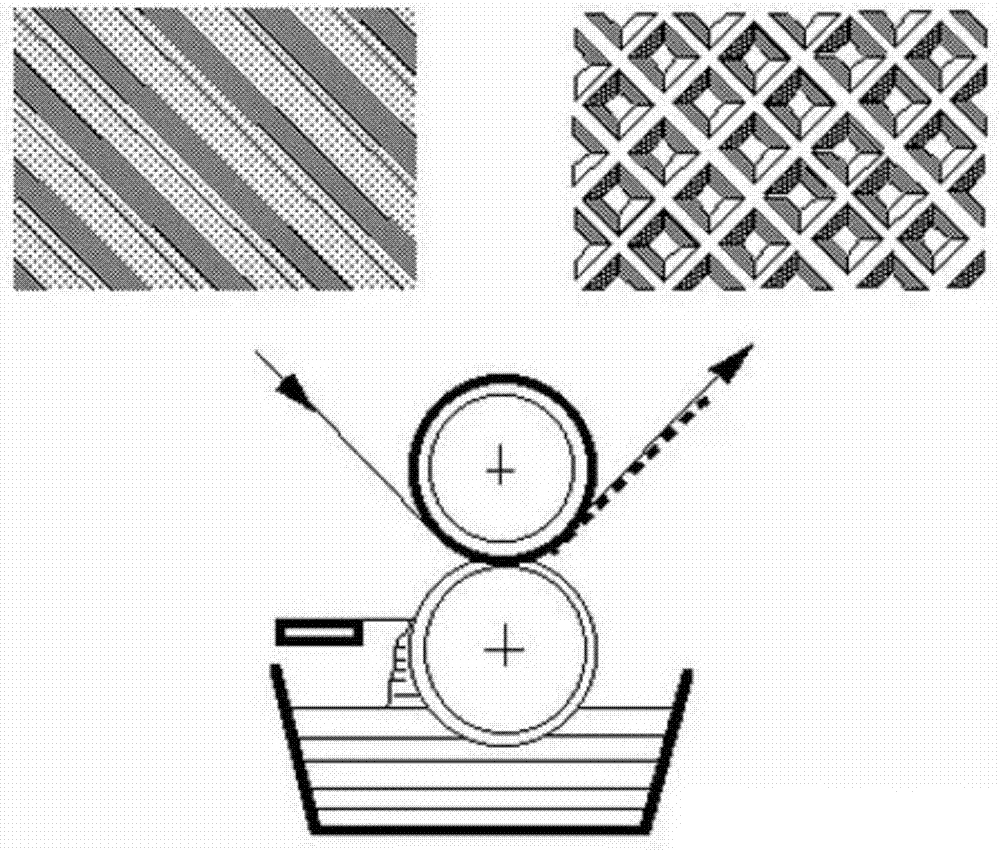

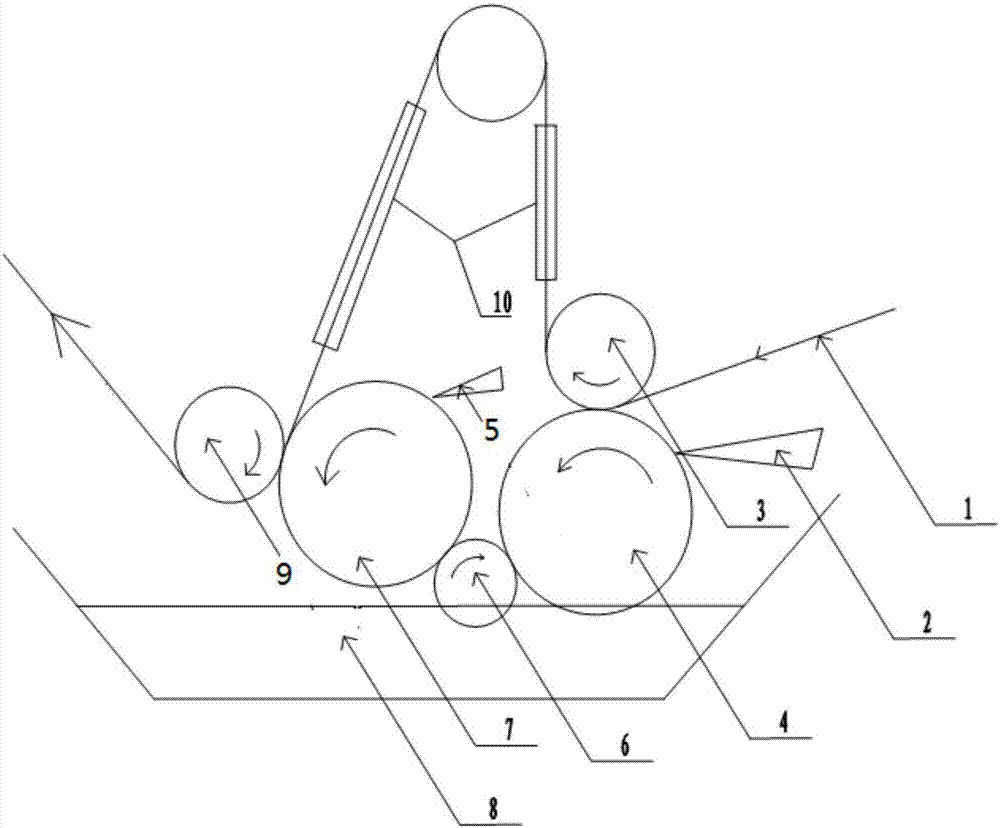

[0025] Such as figure 2 As shown, the substrate 1 enters the first coating mechanism and passes through the first mesh roller 4 to carry the material. After the first scraper 2 is scraped off, the coating is coated on the substrate 1 under the pressure of the first pressure roller 3, and passes through the oven 10. It enters the second coating mechanism composed of the second screen roll 7 and the second pressure roll 9. After the first screen roll 4 finishes coating, it is attached to the defoaming rubber roll 6 to prevent air from entering the first screen roll 4 and prevent air bubbles from appearing in the first coating.

[0026] The paint in the trough 8 is transferred to the second screen roller 7 through the defoaming rubber roller 6, and after being scraped by the second scraper 5, it is bonded with the base material under the pressure of the second pressure roller 9, and the The coating is transferred to the base material to complete the secondary coating.

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com