Inner hexagonal piston rod hydraulic cylinder

A technology of piston rod and hydraulic cylinder, applied in the direction of fluid pressure actuating device, etc., can solve the problem that the wrench cannot be inserted, and save time and manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

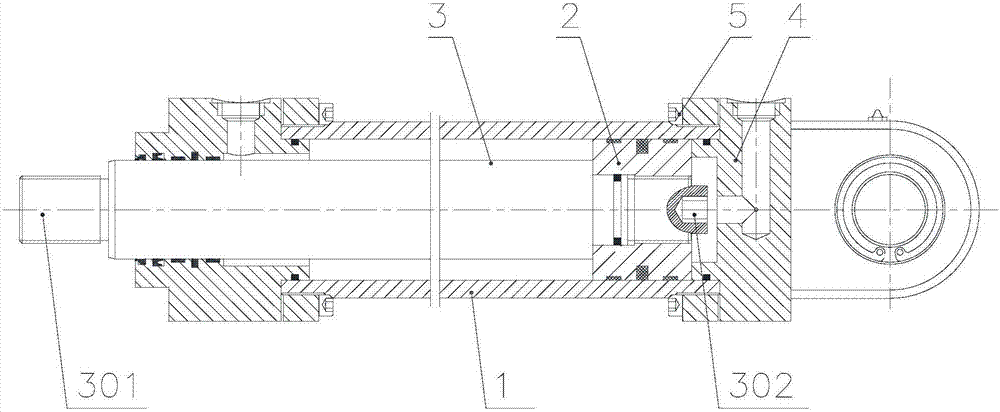

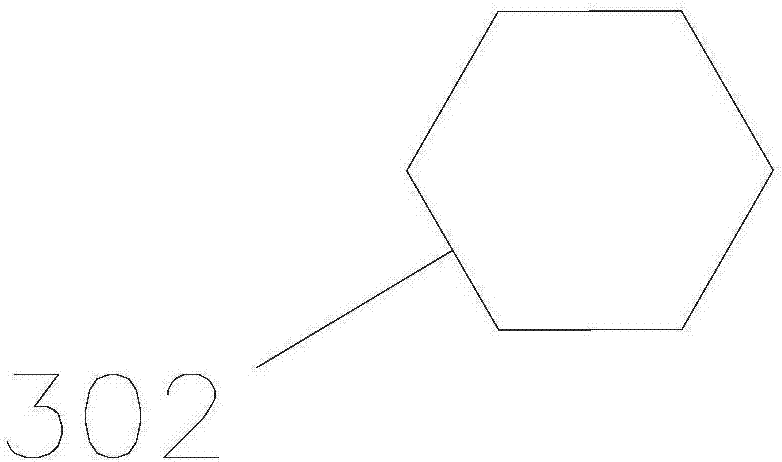

[0016] Such as Figure 1-2 As shown, a hexagonal inner piston rod hydraulic cylinder includes a cylinder body 1, a piston 2, a piston rod 3 and a cylinder bottom 4. The piston 2 is slidably arranged in the cylinder body 1, and one end of the piston rod 3 is arranged On the piston 2, the other end of the piston rod 3 extends out of the cylinder 1, the end of the piston rod 3 away from the piston 2 is provided with a threaded connection portion 301, and the cylinder bottom 4 is fixedly connected to One end of the cylinder 1 away from the threaded connection portion 301, one end of the piston rod 3 is provided with a disassembly hole 302 for matching tools and driving the piston rod 3 to rotate. The disassembly hole 302 is located at the piston rod 3 near the cylinder bottom 4 One end.

[0017] The cross-sectional shape of the disassembly hole 302 is a polygonal structure. The disassembly hole 302 is an inner hexagonal hole.

[0018] When the above-mentioned hexagonal inner piston ...

Embodiment 2

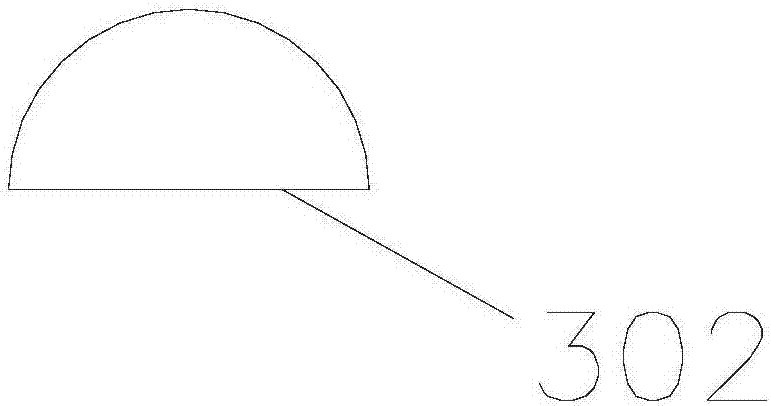

[0020] The difference between embodiment 2 and embodiment 1 lies in: image 3 As shown, the cross-sectional shape of the disassembly hole 302 is a semicircular structure. Setting a wrench that matches the cross-sectional shape of the disassembly hole 302 can make the piston rod 3 rotate, thereby disassembling the piston rod 3 and the connecting device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com