Self-balanced anti-fatigue testing platform of large-size cantilever type bearing structure

A load-bearing structure and self-balancing technology, which is applied in the field of anti-fatigue experiments, can solve problems such as poor load conditions in the foundation area, easy damage to the foundation, and large local loads at the anchorage point at the fixed end, so as to achieve a firm structure of the tooling body and avoid fatigue The effect of loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

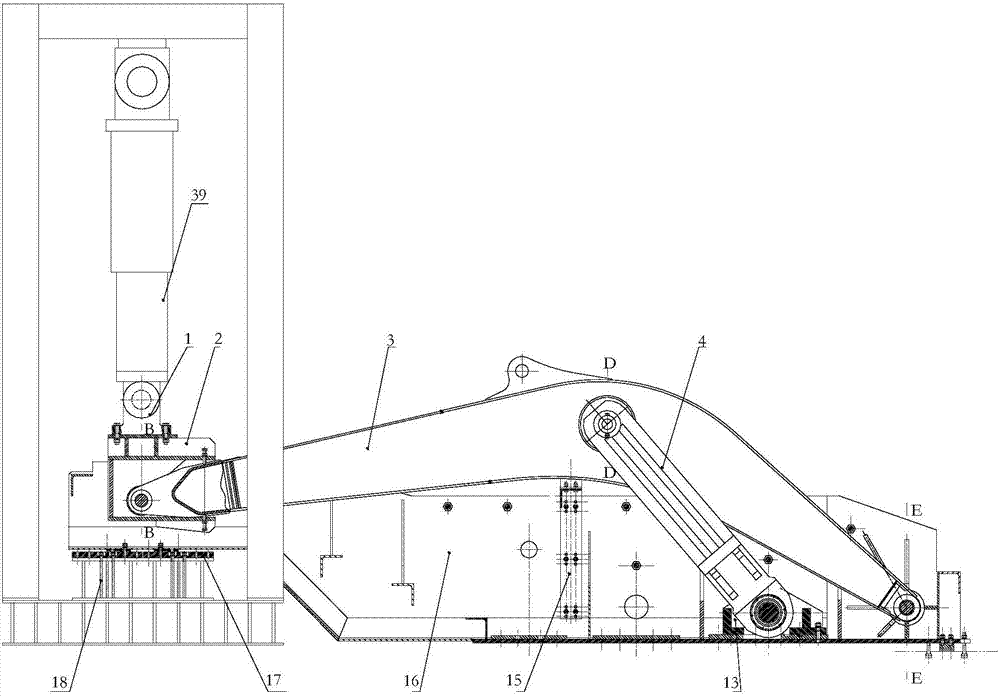

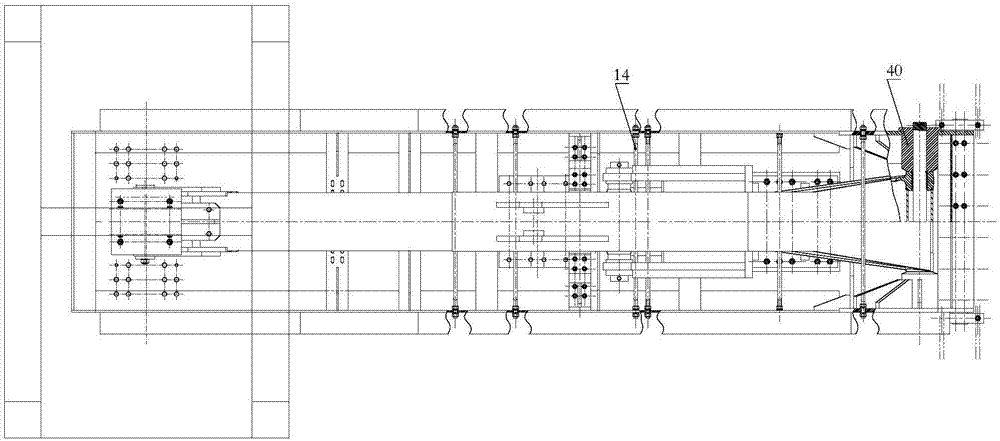

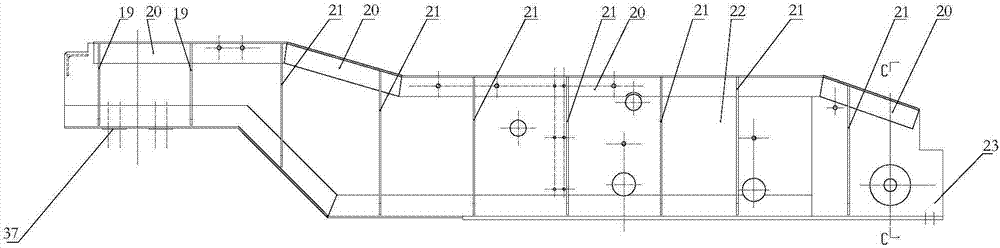

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] In the following, the end where the actuator 39 is located is taken as the left, and the actuator 39 is located above the force applying frame 2, which is only for describing the present invention more clearly, rather than limiting the present invention.

[0034] Such as Figure 1 to Figure 2 As shown, the present invention comprises a bearing frame, a tooling body 16 installed on the carrier frame, a test piece 3, and a force-applying frame 2. The carrier frame is connected with the beam below the column of the fatigue testing machine by bolts, and the left end of the tooling body 16 passes through the first A screw is fixed on the bearing frame, and the right end of the tooling body 16 is fastened to the T-shaped groove on the foundation by bolts. The test piece 3 is a cantilever structure fatigue test piece, and the right end of the test piece 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com