Method and device for identifying pitch angle consistency deviation based on blade load

An identification method and pitch angle technology, which is applied in the monitoring of wind turbines, wind power generation, wind turbines, etc., can solve the problems of three-blade pitch angle deviation, difficulty in effectively identifying wind turbines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

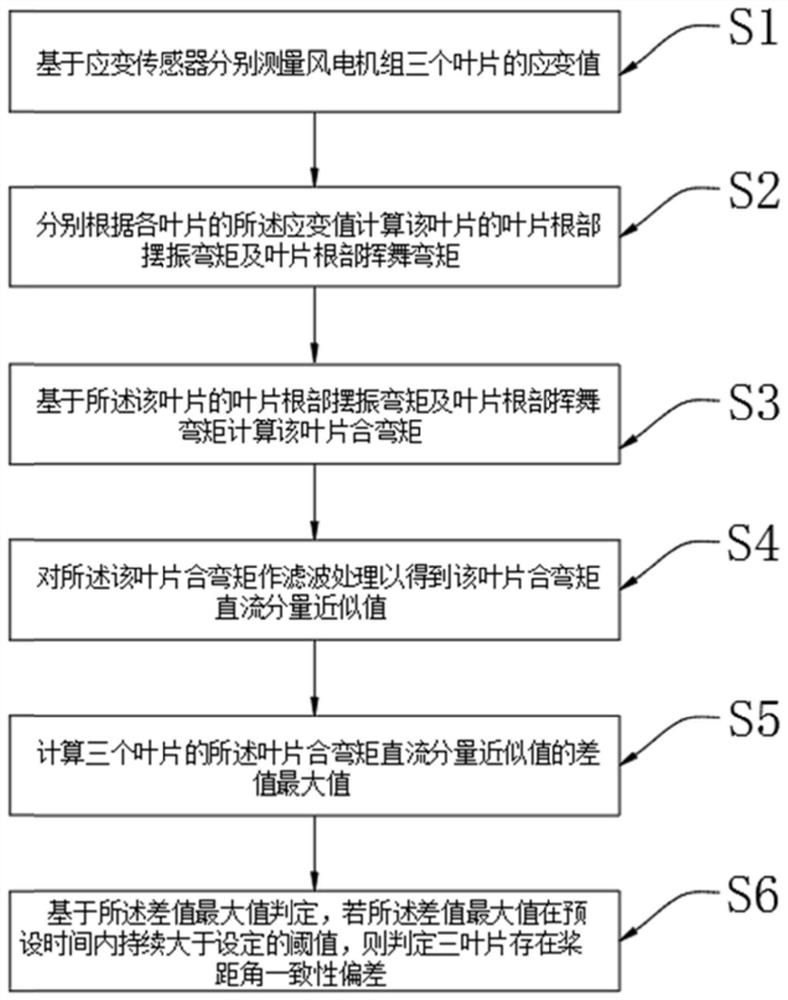

[0039] see figure 1 , the present invention provides a method for identifying deviations of pitch angle consistency based on blade loads, comprising the following steps:

[0040] S1. Measure the strain values of the three blades of the wind turbine based on the strain sensor respectively;

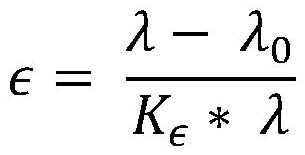

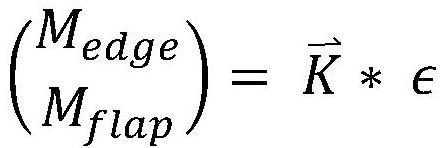

[0041] S2. Calculating the blade root shimmy bending moment and the blade root flapping moment of the blade according to the strain values of each blade respectively;

[0042] S3. Calculate the combined bending moment of the blade based on the shimmy bending moment at the blade root and the swinging bending moment at the blade root;

[0043] S4. Filtering the resulting blade bending moment to obtain an approximate value of the DC component of the blade resulting bending moment;

[0044] S5. Calculating the maximum value of the difference between the approximate values of the direct current component of the combined bending moment of the blades of the three blades;

[0045] S6. Base...

Embodiment 2

[0062] The present invention also provides a pitch angle consistency deviation identification device based on blade load, comprising:

[0063] The measurement module is used to respectively measure the strain values of the three blades of the wind turbine based on the strain sensor, and transmit the strain values of each blade to the processing module;

[0064] The processing module is configured to receive the strain values of the blades returned by the measurement module, and calculate the blade root shimmy bending moment and the blade root flapping moment of the blade according to the strain values of each blade respectively, and based on the The shimmy bending moment of the blade root of the blade and the flailing bending moment of the blade root are used to calculate the combined bending moment of the blade; it is also used to filter the combined bending moment of the blade to obtain the approximate value of the DC component of the combined bending moment of the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com