Axial direction magnetic flux motor packaging stator inner insert

A technology of axial magnetic flux and inserts, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of difficult production, high processing and manufacturing costs, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

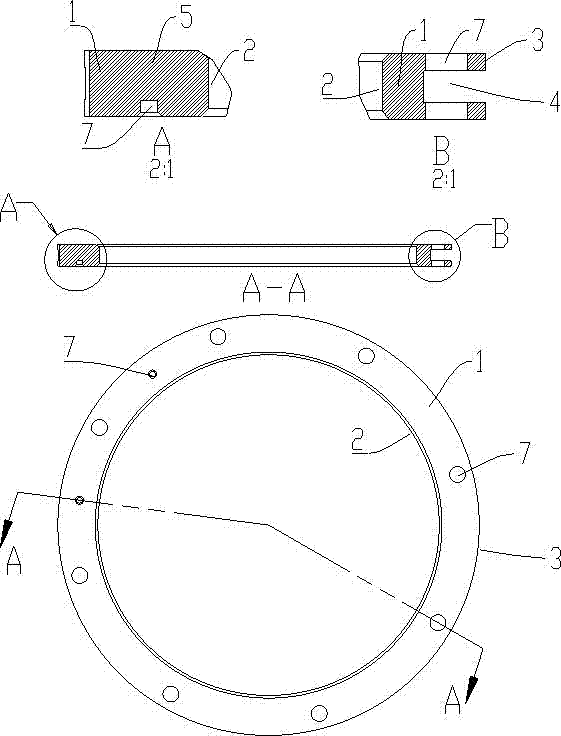

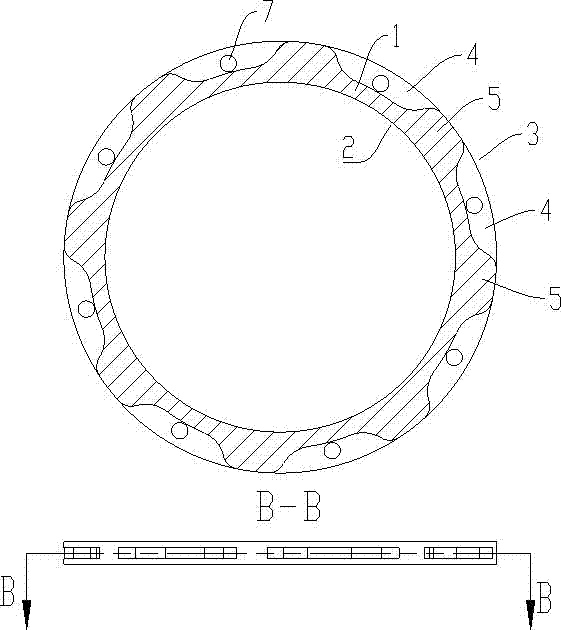

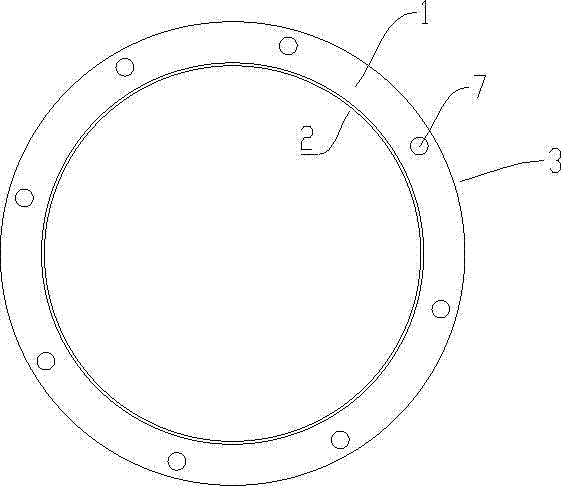

[0011] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the axial flux motor packaging stator inner insert of the present invention is connected by the inner edge (2) of the inlay (1) and the outer circular inlay edge (3) of the inlay (1), and the inner edge (2) The shape can be any shape. There is a hollow position (4) inside the mosaic body (1) and the outer circular mosaic edge (3), which is used for packing filler. Between the hollowed out position (4) and the hollowed out position (4), it is connected with the spacer position (5) for reinforcement. When the motor is a three-phase axial flux motor with an outer rotor, there are phase electrode avoidance positions (6) on the inner sides of the inlay (1) and the outer circular inlay (3), which are used for placing and assembling the phase electrode PCB boards. When the motor is an inner rotor three-phase axial flux motor, the phase electrode avoidance hollowing out position (6) is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com