An axial flux motor Ding stator

An axial magnetic flux and stator technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of difficult application and popularization of high-efficiency and energy-saving motors, low production efficiency, and high processing and manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

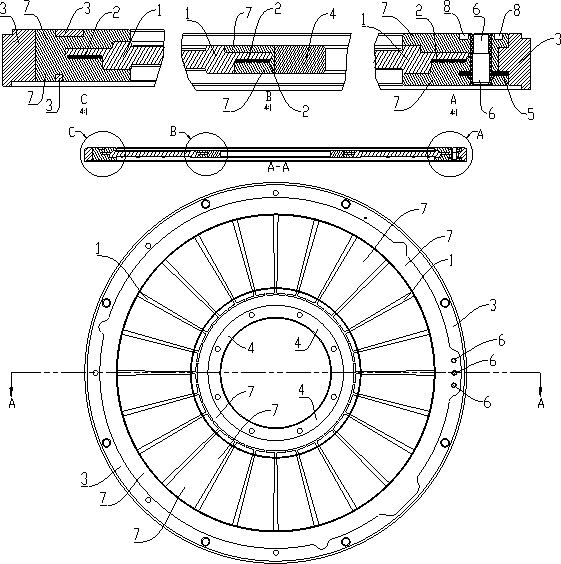

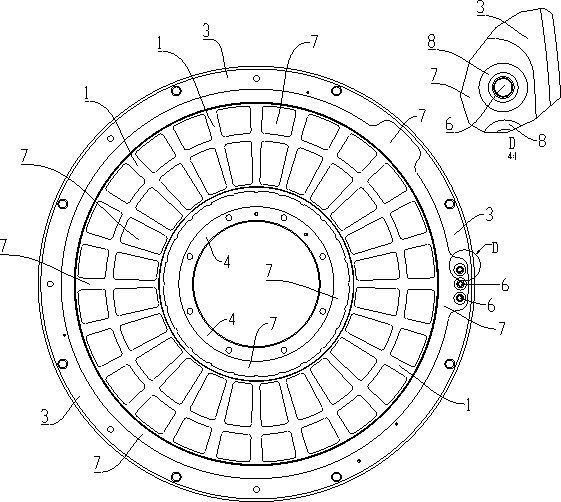

[0011] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the Ding stator of the axial flux motor of the present invention is composed of the produced winding bracket (1), coil group (2), outer insert (3), inner insert (4), phase electrode PCB Plate (5), phase electrode connector (6), package body (7), phase electrode waterproof ring groove (8); the coil group (2) is wound on the produced winding bracket (1) as required The coil group of the wire, the number of coil groups is equal to the number of motor phases; the outer inlay (3) is the outer inlay that has been produced according to the requirements, and the inner inlay (4) is the inner inlay that has been produced according to the requirements, and the outer inlay is used Part (3) and inner insert (4) are mainly to increase the product structure strength and product precision of the Ding stator, simplify the vacuum packaging mold, and facilitate vacuum packaging; the phase electrode P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com