A magnetic pole opposite to that of an axial flux motor is double-sided attache to a rotor bracket

A technology of opposite magnetic poles and axial magnetic flux, applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc., can solve problems such as easy loosening of screws, difficulty in popularizing motors, and damage to stators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

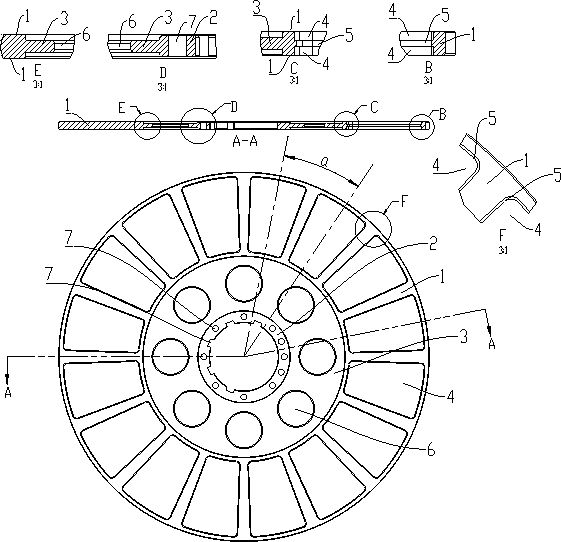

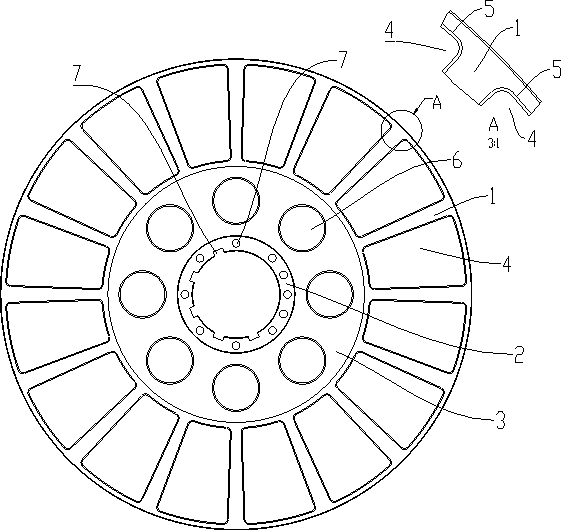

[0011] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the opposite-sex magnetic poles of the axial flux motor of the present invention are double-sidedly bonded to the rotor bracket. The air gap body (1) and the power transmission body (2) are connected through the coupling body (3), and the air gap body (1) has Evenly distributed hollowing positions (4) according to the shape of magnetic poles, the number of hollowing positions (4) = number of motor pole pairs * 2, angle a = 360 degrees / (number of motor pole pairs * 2), in the hollowing position (4) There are convex shoulders (5) connected inside, and the processed magnetic poles are put into the hollowed out position (4) from the upper and lower sides in the way of bonding the opposite sides of the magnetic poles, and the convex shoulders (5) respectively clamp and position the upper and lower magnetic poles, so that The strong suction force of the upper and lower magnetic poles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com