Wheel balance automatic correcting device

An automatic and balanced technology, applied in the direction of metal processing equipment, etc., can solve the problems of reduced production efficiency, affecting the beat of the production line, and low accuracy, so as to reduce the incidence of accidents, meet the fast-paced production, and achieve the effect of low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

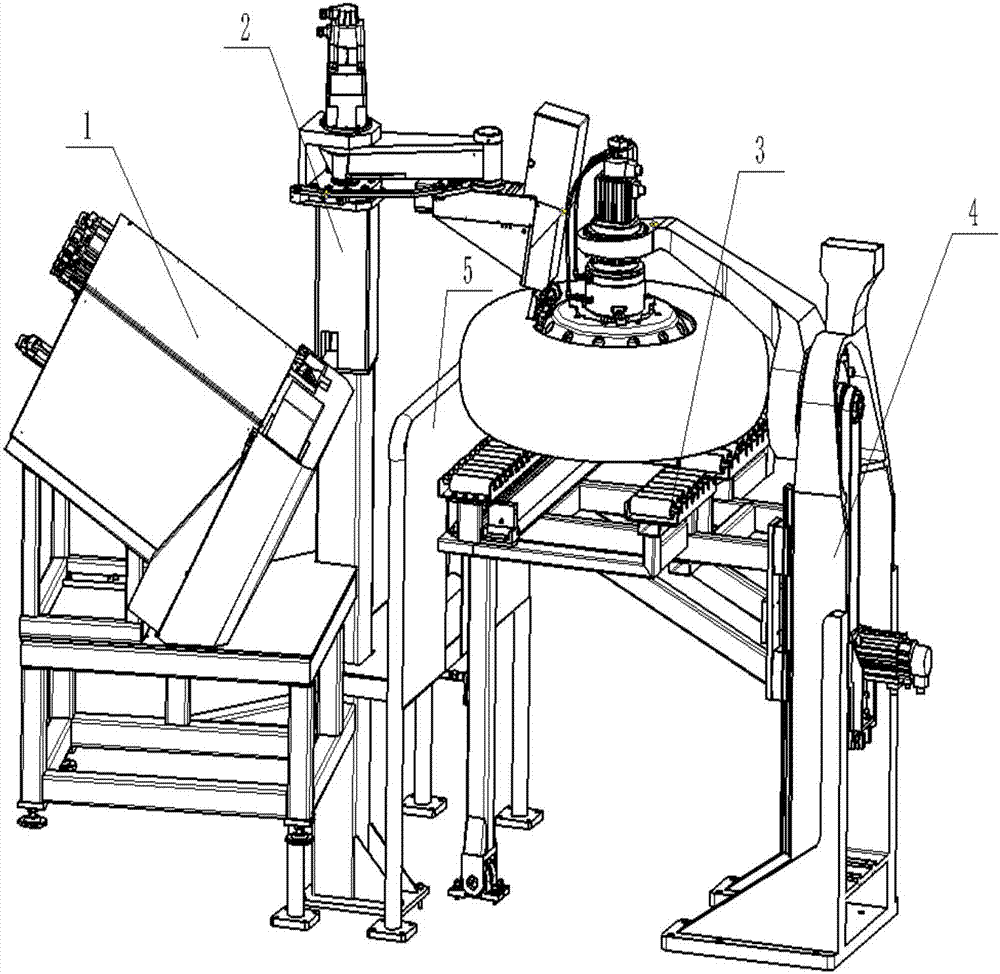

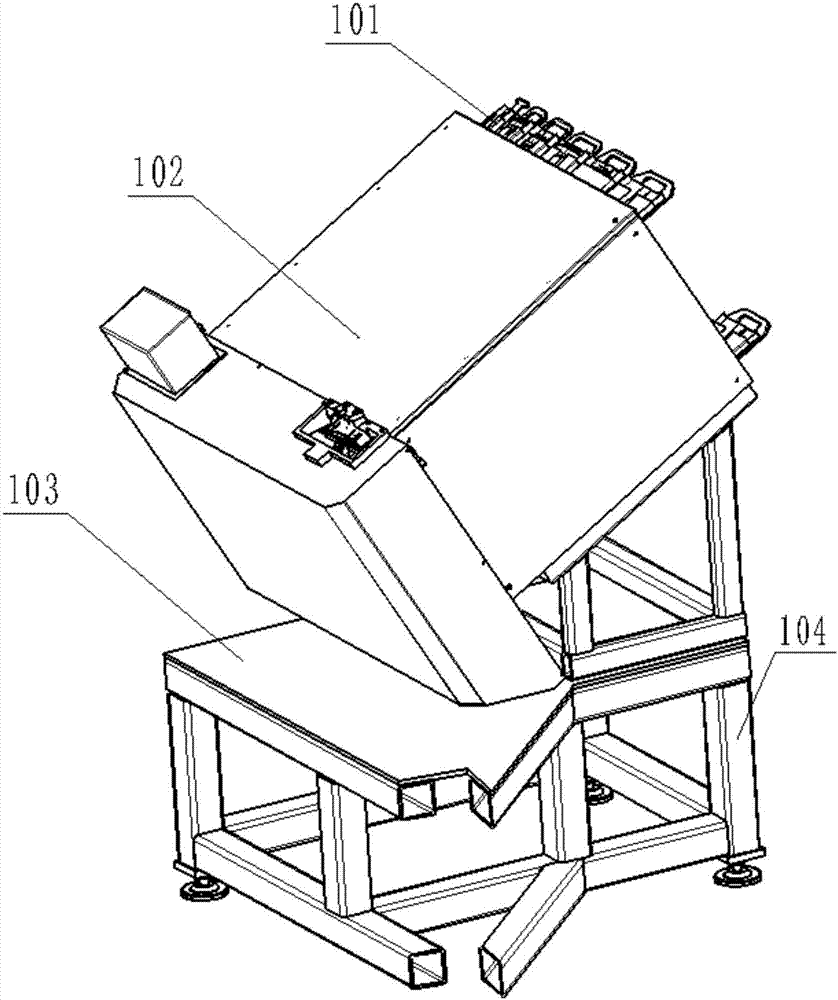

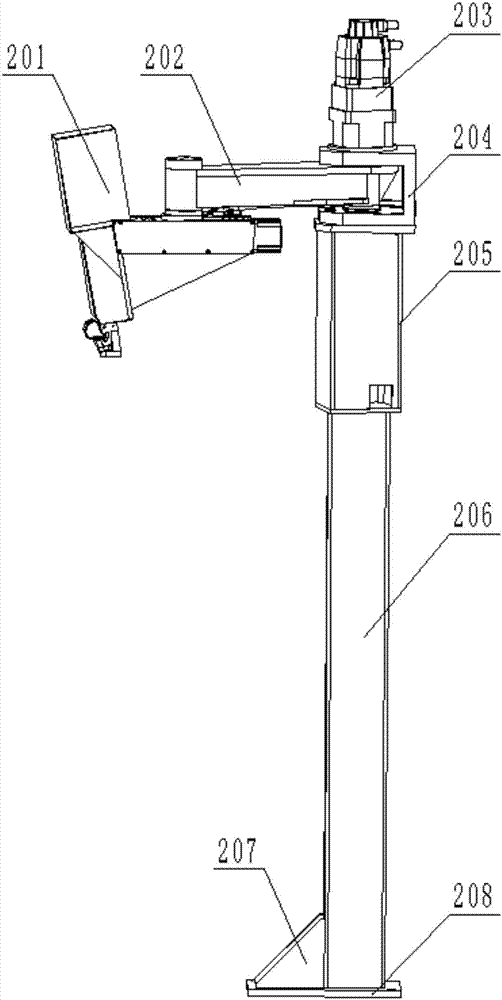

[0011] Such as figure 1 As shown, a wheel balance automatic correction device is composed of a discharge mechanism (1), a block mechanism (2), a correction tray mechanism (3), a turning mechanism (4), and a guardrail (5), wherein the discharge mechanism ( The discharge support frame (104) in 1) and the height bracket II (206) in the block mechanism (2) are connected by welding to realize the function of structural stability; the height bracket II (206) in the block mechanism (2) ) and the guardrail bracket (503) in the guardrail (5) are connected by welding to realize the function of structural stability; the slide block (301) in the tray mechanism (3) and the slide rail (407) in the turning mechanism (4) are corrected It is a gap fit connection to realize the function of correcting the movement of the pallet mechanism (3) up and down to lift the wheel (401); correct the cylinder connection block (306) in the pallet mechanism (3) and the cylinder push head (502) in the guardra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com