Laser marking method and marking device for IC card

A laser marking method and laser marking technology, which are applied in the field of IC card laser marking methods and marking devices, can solve the problems of low equipment production capacity and low marking efficiency of marking devices, so as to improve production capacity and reduce laser marking. The effect of marking the average time and improving the efficiency of laser marking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with specific embodiments, but the present invention is not limited thereto.

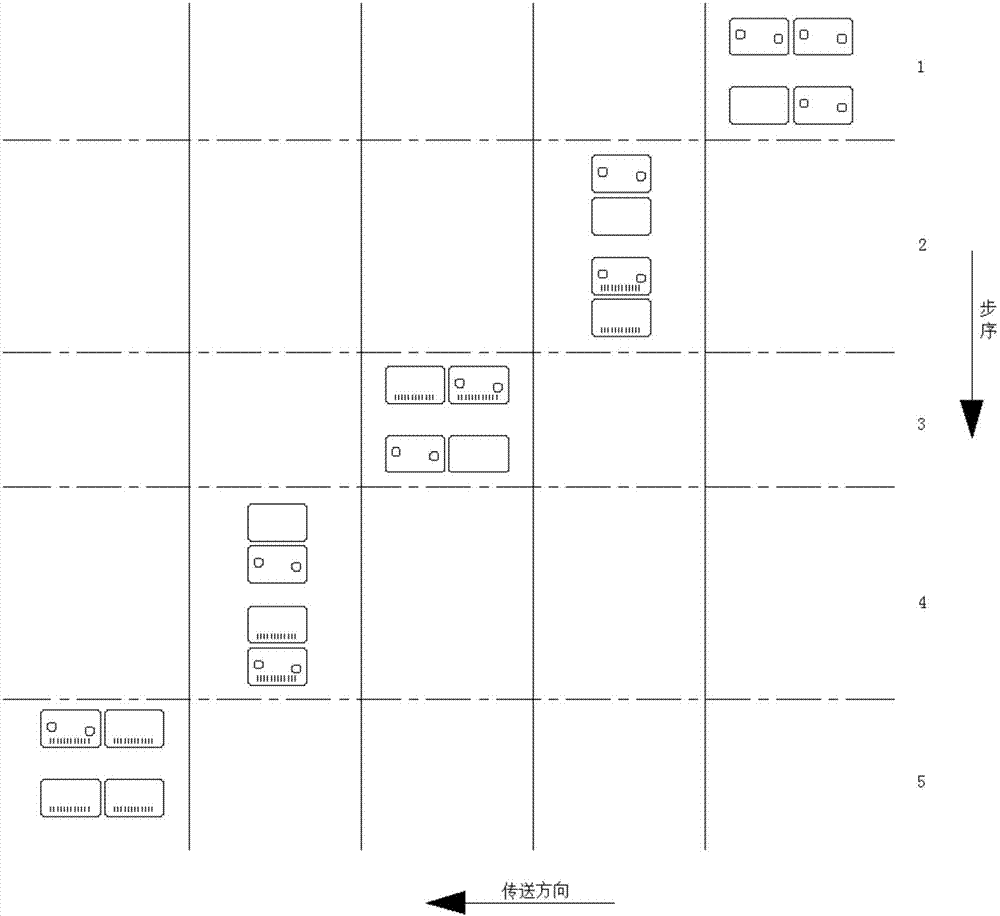

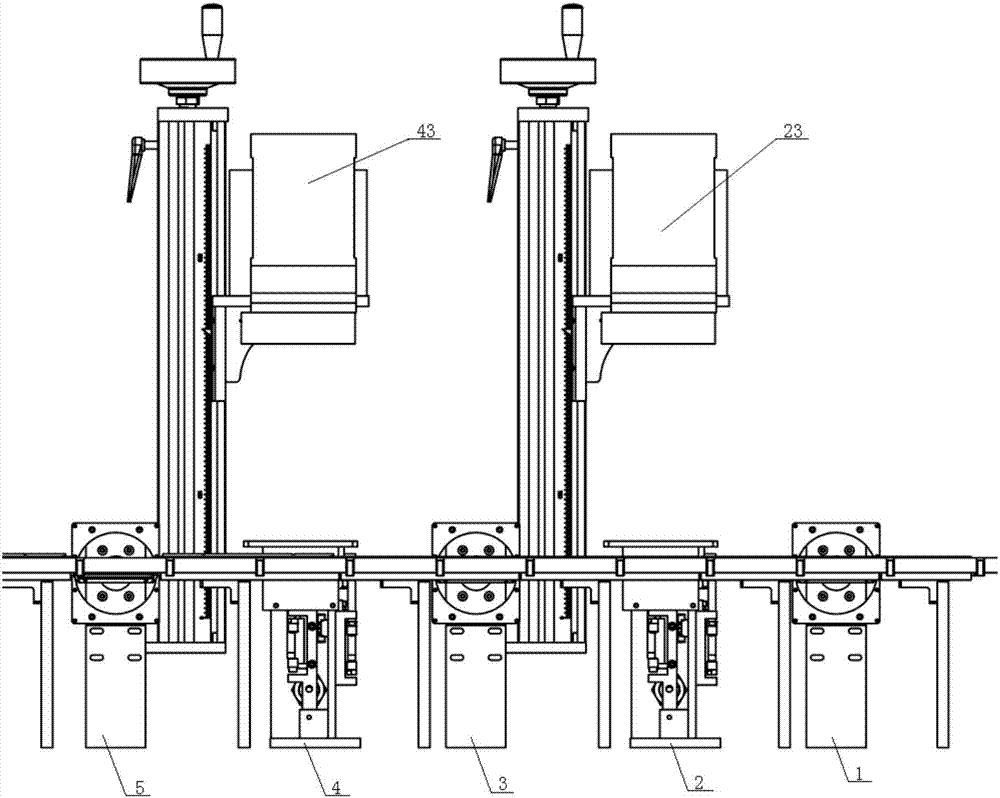

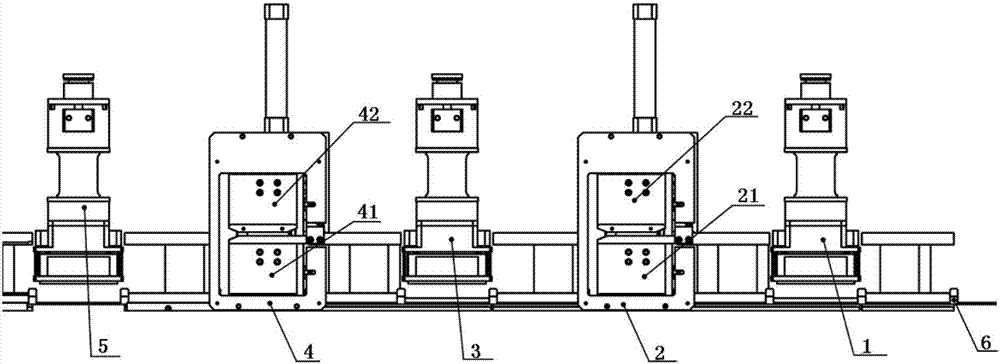

[0029] In order to solve the problems of low IC card laser marking efficiency and low equipment capacity in the past, the present invention provides an IC card laser marking method, which is used to perform double-sided marking on the IC card to be marked with the same side facing the same side. Marking, specifically includes the following steps:

[0030] 1) Turn over the intervals of the IC cards to be marked, so that the IC cards are arranged alternately on the front and back sides;

[0031] 2) Send the IC cards to be marked alternately arranged on the front and back to the first laser marking device in sequence. After receiving the IC cards, the first laser marking device will move the IC cards to the working area On position I and position II, where there is at most one IC card on position I and position II with the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com