Anti-pulling and anti-skid foundation and construction method thereof

A foundation and foundation slab technology, which is applied in foundation structure engineering, earthwork drilling, surveying, etc., can solve the problems of difficult construction, long time and high cost, and achieve the effect of superior performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

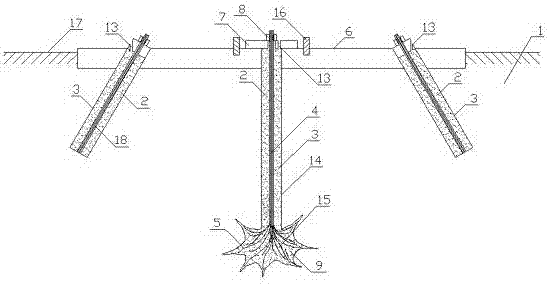

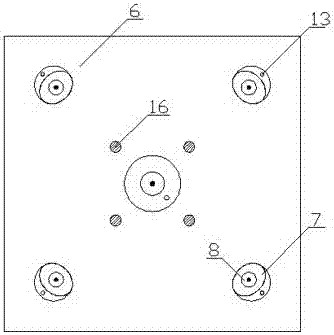

[0039] Such as Figure 1~3 As shown, the anti-pull and anti-skid foundation includes a square base plate 6 embedded in the foundation and the upper surface is higher than the ground 17, a set of hair anchor rod body 4, several full-length bonded anchor rods 18 and respectively connected with the hair and hair bolts. Anchor rod body 4 is matched with pad 7 and anchor plate 8 of full-length bonded anchor rod 18.

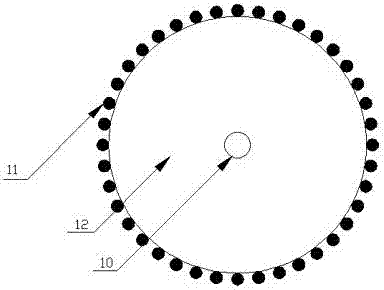

[0040] The center of the foundation plate 6 is provided with an anchor hole I, and each corner is provided with an anchor hole II; each spacer 7 is provided with an anchor hole III in the center; the bottom end of the hair anchor body 4 is anchored , the top of which passes through anchor hole I, and connects with anchor plate 8 through anchor hole III; hair anchor body 4 is composed of tensile filament 11, that is, it is made of Steel wire or (and) other wires. The lower part of the tensile filament 11 is bundled with the water-resistant explosive 12 equipped with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com