Auxiliary frame for electronic component welding

A technology of electronic components and auxiliary racks, applied in welding/cutting auxiliary equipment, auxiliary devices, welding equipment, etc., can solve the problems of wires on the workbench, holding the circuit board to make it leave the workbench, etc., to achieve applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

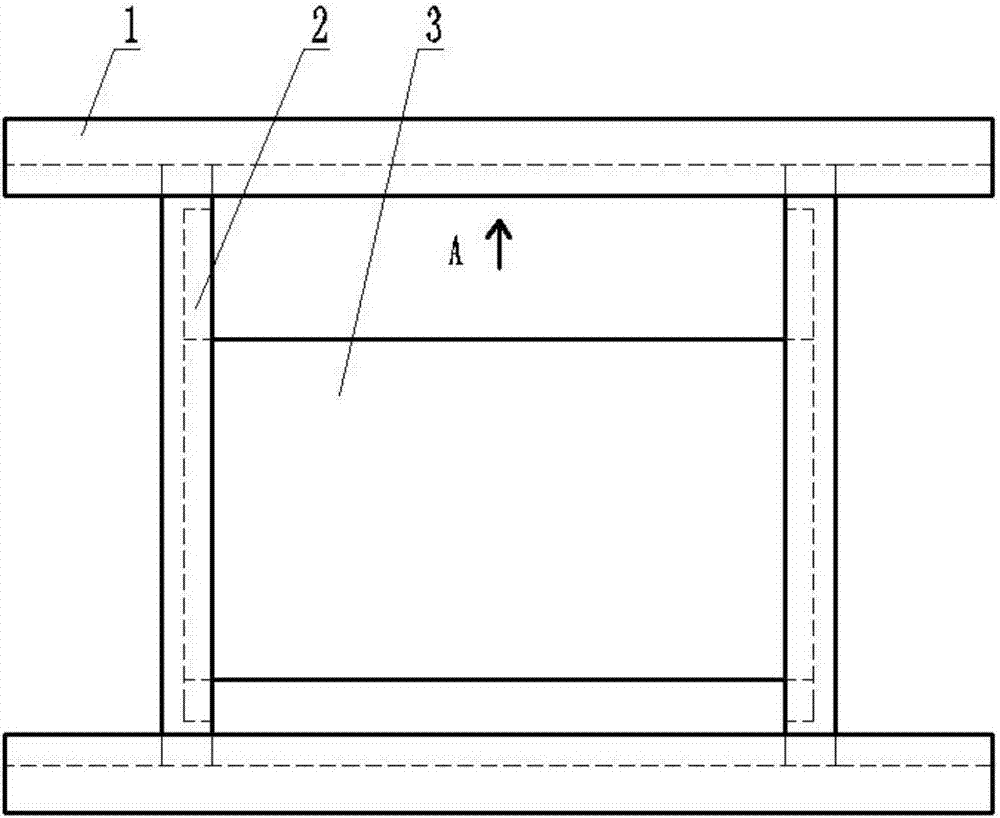

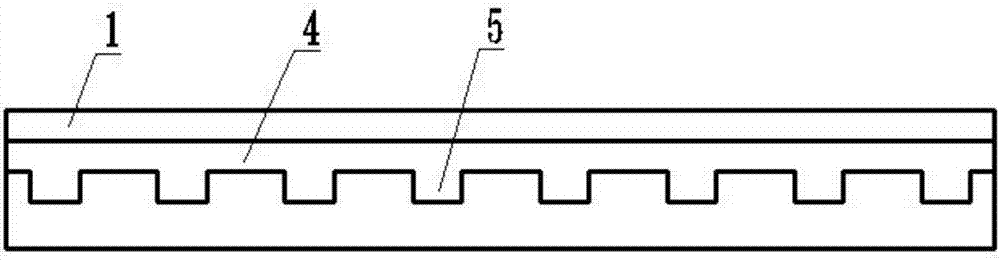

[0014] An auxiliary frame for welding electronic components, comprising two horizontal strip-shaped support blocks 1 and two longitudinal support plates 2, the two horizontal strip-shaped support blocks are placed in parallel and spaced apart, and guide grooves are mirror-symmetrically formed on the opposite surfaces of the two horizontal strip-shaped support blocks 4. Slidingly install two longitudinal support plates in the guide groove between the two horizontal bar support blocks. There are slots formed in the mirror image symmetry on the opposite surface of the two longitudinal support plates, and insert them into the slots between the two longitudinal support plates. circuit board3.

[0015] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com