Guiding assembly and bag-open technology using guiding assembly

A technology for guiding components and guiding strips, applied in sewing machine components, textiles and papermaking, sewing equipment, etc., can solve problems such as affecting aesthetics, and achieve the effects of improving production efficiency, maintaining smooth lines, and improving aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

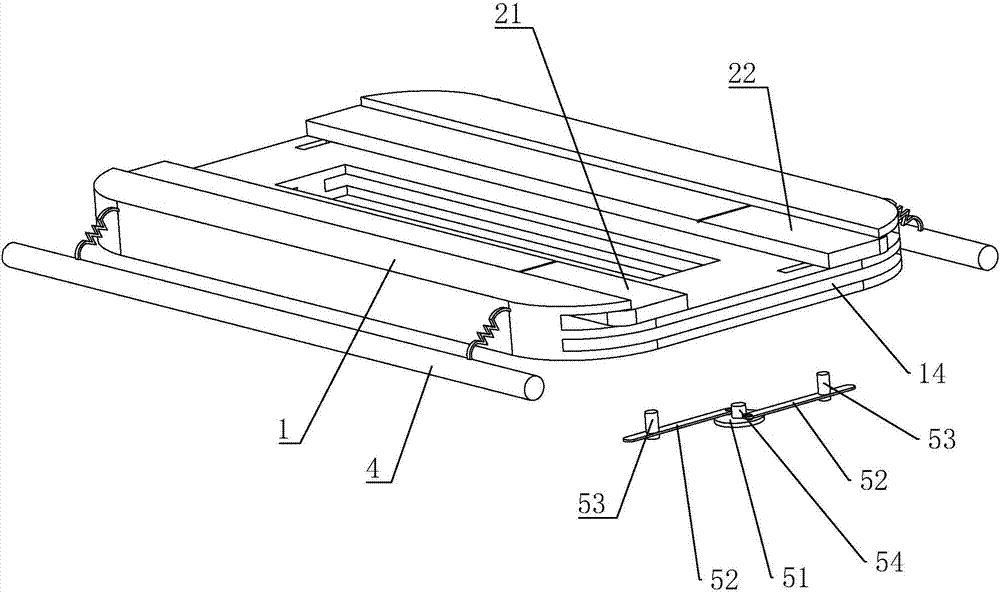

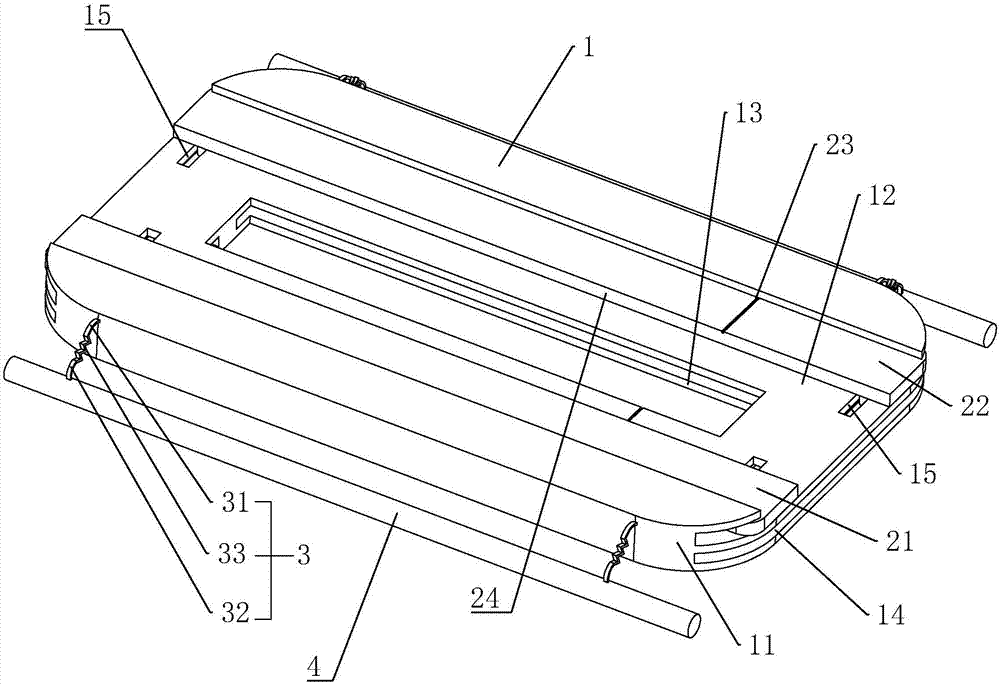

[0048] Embodiment 1: A kind of guiding component, such as figure 1 and figure 2 As shown, the guide plate 1 is included, and the guide plate 1 is elongated, and arc-shaped surfaces 11 are provided on both sides of the guide plate 1 in the width direction.

[0049] A placement groove 12 is provided on the guide plate 1 along its length direction, and a first guide strip 21 and a second guide strip 22 are placed in the placement groove 12, and the first guide strip and the second guide strip 22 are long plates. shape, and the length direction is parallel to the longitudinal direction of the placement groove 12 and the guide plate 1; the width direction is parallel to the width direction of the placement groove 12 and the guide plate 1. The upper and lower surfaces of the first guide bar 21 and the second guide bar 22 are both in contact with the inner wall of the placement groove 12 .

[0050] In order to enable the first guide bar 21 and the second guide bar 22 to move simul...

Embodiment 2

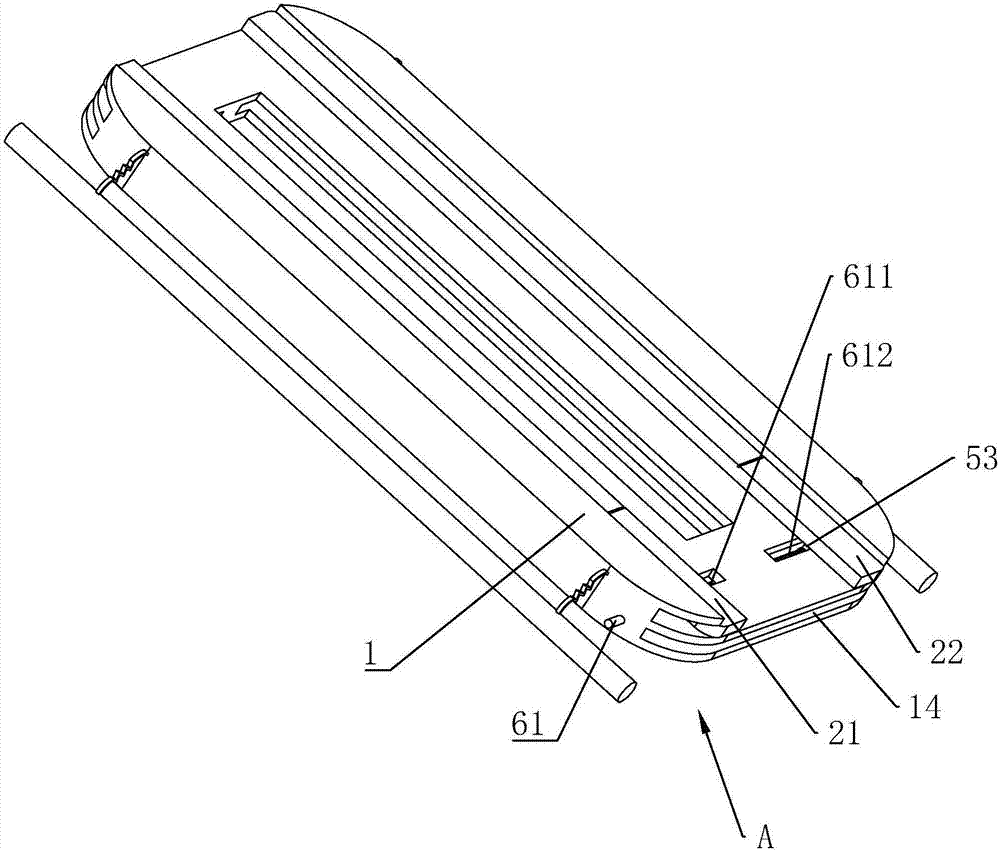

[0056] Embodiment 2: A boot component, such as Figure 3 to Figure 5 As shown, the difference with embodiment 1 is that the linkage plate 51 is removed (see figure 2 )setting.

[0057] Through a strip-shaped threaded mandrel 61 on the guide plate 1, the threaded mandrel 61 is provided with a total of two reverse threads of the first thread 611 and the second thread 612, and one end of the threaded mandrel 61 passes through the guide plate 1. The other end is placed in the installation groove 14 and connected with the inner wall of the installation groove 14 through the bearing 64 .

[0058] The first thread 611 is sleeved and threaded with a first guide sleeve 62 , the second thread 612 is sleeved and threaded with a second guide sleeve 63 , and the first guide sleeve 62 is fixed to the first guide bar 21 through the guide post 53 The second guide sleeve 63 is fixedly connected with the second guide bar 22 through the guide post 53 .

[0059] When in use, by rotating the s...

Embodiment 3

[0060] Embodiment 3: a kind of boot assembly, such as Figure 6 to Figure 8 As shown, the difference with embodiment 1 is that the linkage plate 51 is removed (see figure 2 )setting.

[0061] The first gear 71 and the second gear 72 meshed with each other are connected by rotation in the installation groove 14 , and the radii of the first gear 71 and the second gear 72 are equal. The first gear 71 meshes with the first rack 73, the second gear 72 meshes with the second rack 74, and the first rack 73 and the second rack 74 are arranged in an L shape; the first rack 73 passes through the guide groove 15 and is fixedly connected with the lower surface of the first guide bar 21 , the second rack 74 passes through the guide groove 15 and is fixedly connected with the lower surface of the second guide bar 22 .

[0062] A guide rod 75 is fixed in the guide groove 15, and the guide rod 75 passes through the first rack 73 and the second rack 74. The length direction of the guide rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com