Peeling testing device and testing method thereof

A technology for testing devices and moving plates, applied in measuring devices, adopting mechanical devices, instruments, etc., can solve the problems of tediousness and high cost, and achieve the effect of strong practicability, simple structure, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

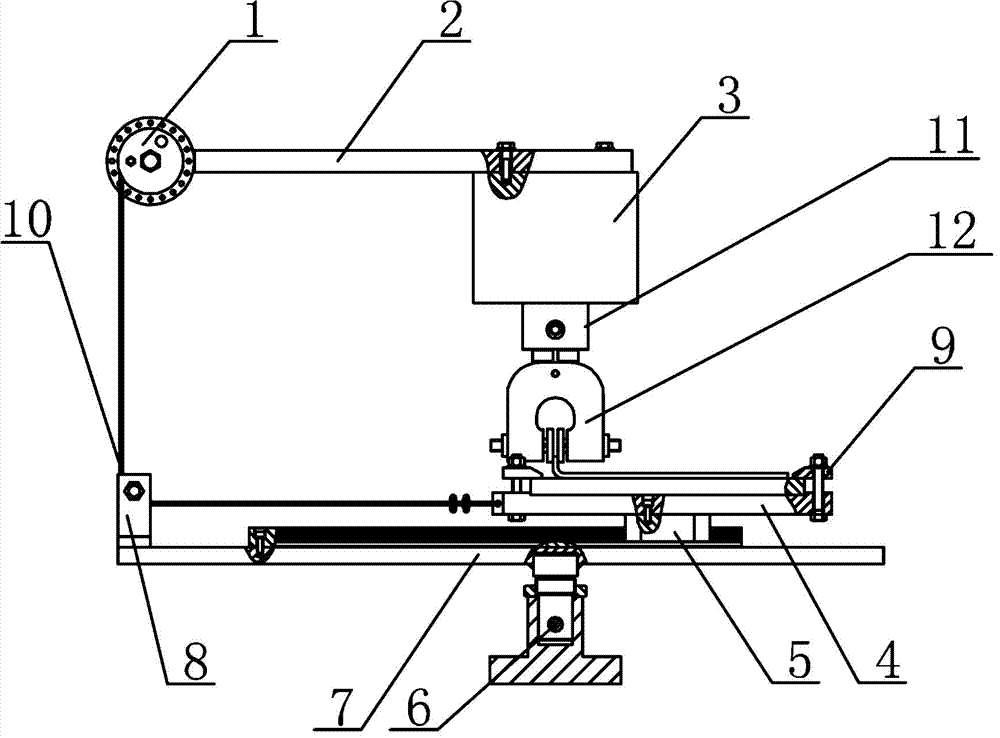

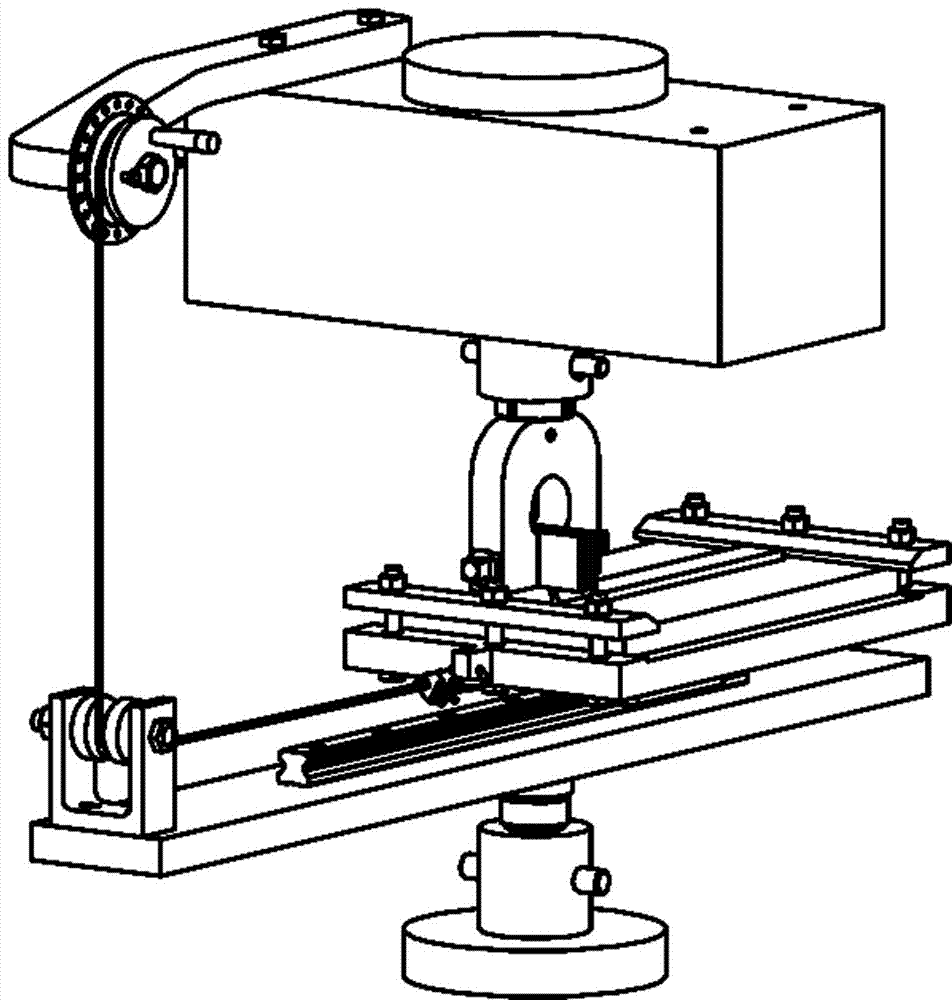

[0020] like Figure 1-Figure 2 As shown, a peeling test device includes a bottom plate 7, a guide rail 5 is installed on the bottom plate, a moving plate 4 is connected to the guide rail, a stretching column 11 of a stretching machine is arranged above the bottom plate, and a connecting seat is installed on the top of the stretching column 11 3. The connecting seat is equipped with a connecting plate 2, and the other end of the connecting plate is installed with a reel 1; one end of the guide wire 10 is connected to the reel 1, and the other end is connected to the moving plate; a clamp is provided under the stretching column 11 12. A pressing plate 9 is provided on the moving plate.

[0021] The stretching machine in this embodiment is Instron Instron5567 stretching machine.

[0022] In a preferred solution, a plurality of threaded holes are installed on the moving plate, and the pressing plate is installed and fixed through the cooperation of bolts and threaded holes. In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com