Improved oil smoke purification device

An oil fume purification and improved technology, applied in the direction of coupling device, oil fume removal, two-part connection device, etc., can solve the problems of arcing or conduction, potential safety hazards, electric shock accidents, etc., to prevent electric shock accidents, high safety, plugging The effect of continuous operation is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

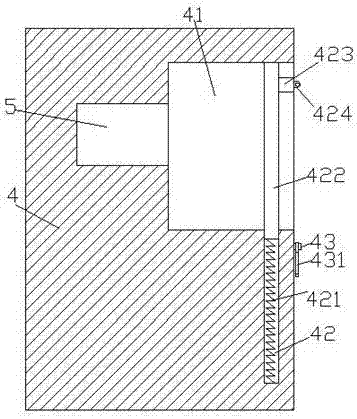

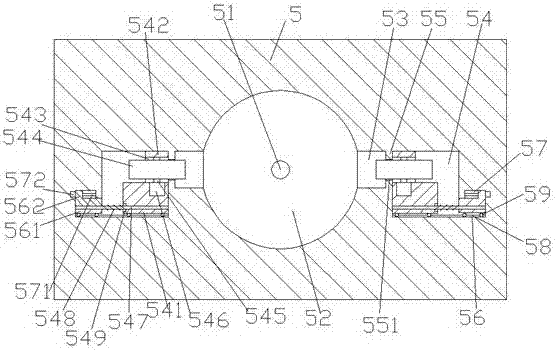

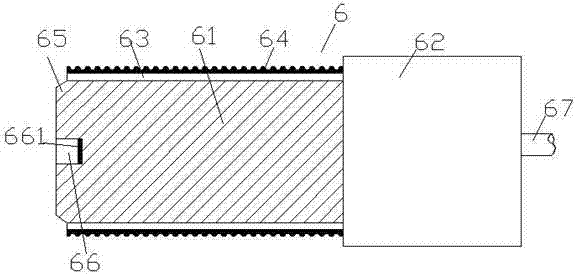

[0020] Such as Figure 1-Figure 4 As shown, an improved oil fume purification device of the present invention includes a body 4 and an electrical connection head 6. A storage tank 41 is provided in the body 4, and an electrical connection part 5 is provided in the inner end surface of the storage tank 41. The electric connection part 5 is provided with an electric connection groove 52, and the electric connection needle 51 is arranged at the center of the inner end surface of the electric connection groove 52, and the left and right sides of the electric connection groove 52 are equally provided along the electric connection groove 52. Stretching guide slots 53, each of the guide slots 53 is provided with a sliding cavity 54 in the electrical coupling part 5 on the side facing away from the electrical coupling slot 52, and the sliding cavity 54 is connected to the electrical coupling part 5. A separation plate 55 is provided between the feeding grooves 53, and a communication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com