Adjustable forced centering support for automatic monitoring devices for high speed rails, railway tunnels, reservoir dams and the like

A monitoring equipment and forced centering technology, applied in mechanical equipment, machine/stand, supporting machine, etc., can solve problems such as limiting the accuracy of measurement and widespread popularization, unable to meet long-term measurement, and the instrument does not move, etc. To achieve the effect of excellent anti-destructive, good protection, and ensure the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

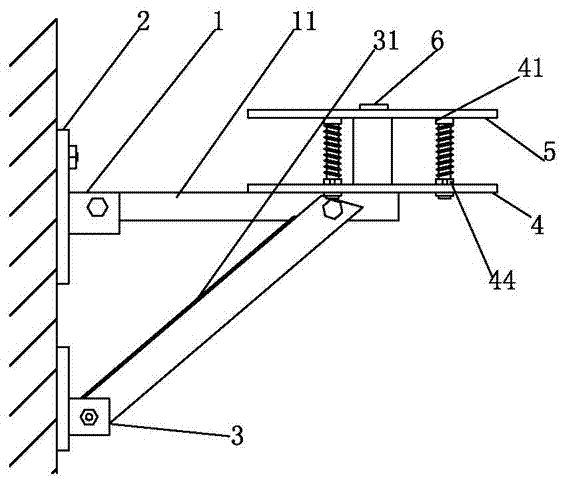

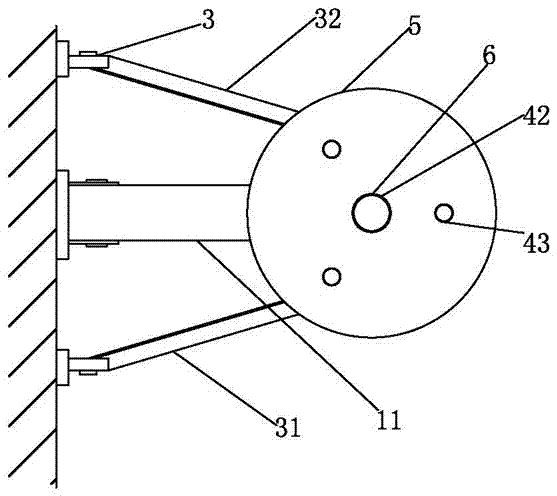

[0012] see Figure 1-2 , in an embodiment of the present invention, an adjustable forced centering support for automatic monitoring equipment such as high-speed railways, subway tunnels, reservoir dams, etc. The fulcrum 3 is fixed on the wall, the upper fulcrum 2 is hinged with a cross bar 11, the lower fulcrum 3 has two, and the two lower fulcrums are hinged with left and right oblique struts (31, 32), left and right oblique struts ( 31, 32) The ends away from the lower fulcrum are respectively hinged on the side of the cross bar 11, the upper end of the cross bar 11 is provided with a base 4, the base 4 is disc-shaped, the base 4 is provided with a plurality of screw holes, and the center of the base is provided with a through hole . The base 4 is provided with a base 5 , the base 5 is disc-shaped, and the base 5 is provided with a plurality of screw holes 43 and through holes 42 matched with the base 4 .

[0013] The installation process is to first fix the upper fulcrum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com