Bilateral buckle type stone powder pressed line provided with concave arc

A concave arc, snap-on technology, applied in the direction of construction and building structure, can solve the problems of affecting the overall effect and aesthetics of decoration, affecting aesthetics, poor firmness, etc. abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

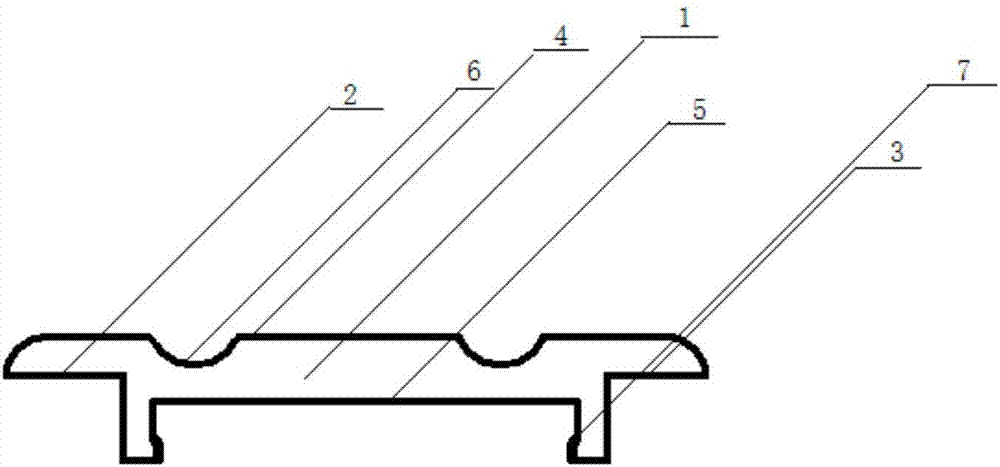

[0015] Embodiment 1: A double-sided buckle-type stone powder pressed line with a concave arc shape. The line body 1 is a slender and long strip pressed by stone powder. The cross-sectional shape of the line body 1 is a long rectangle. The bottom of the line body 1 is set There is a bottom surface 5, the two ends of the bottom surface 5 are provided with the left pressing block 2 and the right pressing block 3 parallel to the bottom surface 5 for pressing the plate, and the middle of the bottom surface 5 is provided with a buckle groove 7 for buckling the line body 1, and the line body 1 There is an upper plane 4 and a concave arc 6 on it.

Embodiment 2

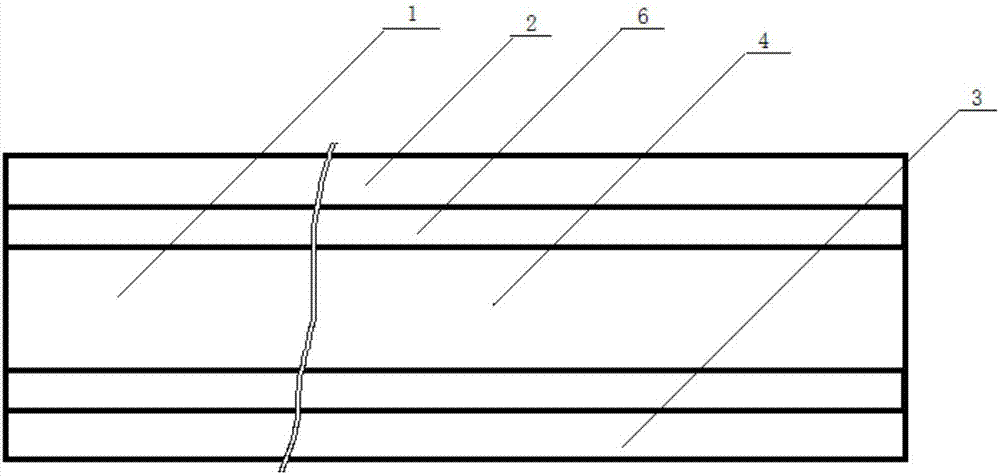

[0016] Embodiment 2: A double-sided buckle-type stone powder pressed line with a concave arc shape. The line body 1 is a slender and long strip pressed by stone powder. The cross-sectional shape of the line body 1 is a long rectangle. The bottom of the line body 1 is set There is a bottom surface 5, the two ends of the bottom surface 5 are provided with the left pressing block 2 and the right pressing block 3 parallel to the bottom surface 5 for pressing the plate, and the middle of the bottom surface 5 is provided with a buckle groove 7 for buckling the line body 1, and the line body 1 There is an upper plane 4 and a concave arc 6 on it. The surface of the strip body 1 is sequentially provided with a pattern layer, a primer protection layer and a wear-resistant layer.

Embodiment 3

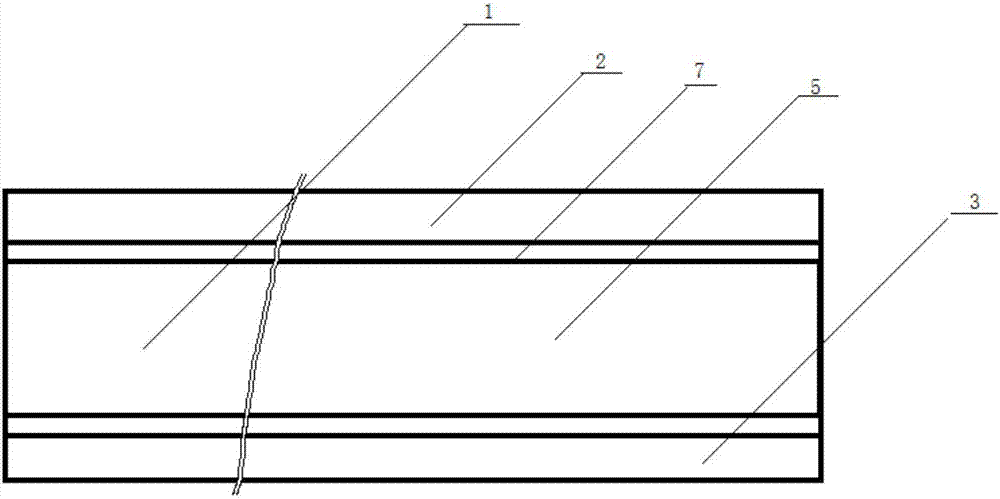

[0017] Embodiment 3: A double-sided buckle-type stone powder pressed line with a concave arc shape. The line body 1 is a slender and long strip pressed by stone powder. The cross-sectional shape of the line body 1 is a long rectangle. The bottom of the line body 1 is set There is a bottom surface 5, the two ends of the bottom surface 5 are provided with the left pressing block 2 and the right pressing block 3 parallel to the bottom surface 5 for pressing the plate, and the middle of the bottom surface 5 is provided with a buckle groove 7 for buckling the line body 1, and the line body 1 There is an upper plane 4 and a concave arc 6 on it. The surface of the strip body 1 is sequentially provided with a pattern layer, a primer protection layer and a wear-resistant layer. Inward protrusions are provided in the buckle groove 7 on the bottom surface 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com