Two-way extruding type packing mechanism

A two-way extrusion and unsealing technology, applied in the directions of sealing/isolation, wellbore/well components, earth-moving drilling, etc. Strong barrier capacity and good annular sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

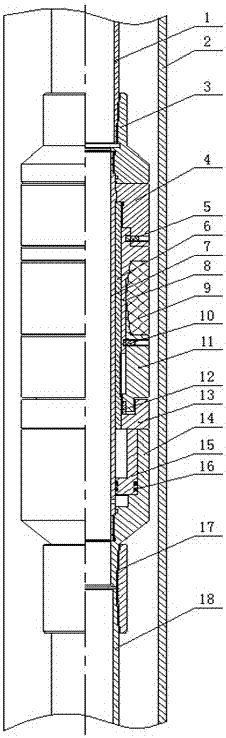

[0015] according to figure 1 , a two-way extrusion type sealing mechanism, the upper joint 3, the unsealing sleeve 4, the unsealing shear nail 5, the support sleeve 6, the central pipe 7, the upper compression sleeve 8, the rubber cylinder 9, the setting shear nail 10, The lower compression ring 11, locking ring 12, adjustment ring 13, lower joint 14, setting piston 15, and O-ring 16 form a two-way extrusion type sealing mechanism. The upper part and the upper oil pipe 1, the lower part and the lower The oil pipe 18 is connected and placed in the casing 2. The central pipe 7 is connected with the upper joint 3 and the lower joint 14 with the upper part of the thread; the support sleeve 4 is outside the central pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com